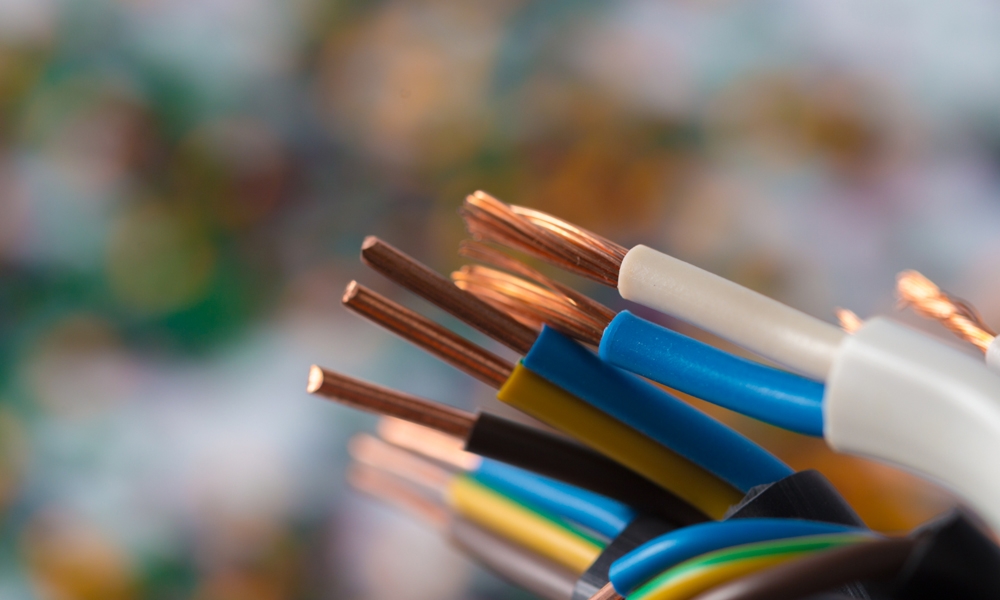

In today's rapidly evolving world, where innovation and technological advancements reign supreme, staying ahead of the curve is essential for businesses across various industries. One area that holds immense importance, yet often goes unnoticed, is wiring harness design. The intricate network of wires and connectors plays a vital role in powering modern-day machinery, vehicles, and electronic systems.

In this blog post, we will explore the fascinating world of wiring harness design and delve into why it is crucial for businesses to be future-ready in this aspect.

The Way Ahead for Wiring Harness Design

The field of wiring harness design is witnessing several advancements and innovations that are shaping the future of this essential technology.

As technology continues to advance, wiring harnesses will play a crucial role in enabling the seamless integration of various systems, supporting the electrification of vehicles, and ensuring reliable data transmission. By embracing these advancements, businesses can stay at the forefront of the rapidly evolving landscape of wiring harness design.

Here are some of the upcoming trends and features:

High-speed Data Transmission As technology evolves, the demand for faster data transmission increases. Wiring harnesses are being designed to support high-speed data transfer, enabling seamless communication between various components and systems.

Lightweight and Compact Designs The pursuit of light weighting and space optimisation will continue to be a driving force in wiring harness design. With the focus on weight reduction and space optimisation, wiring harnesses employ lightweight materials and compact designs. This not only enhances overall system efficiency but also allows for easier installation and maintenance.

Intelligent and Adaptive Systems Wiring harnesses will integrate intelligent features and adaptive systems. These harnesses can self-diagnose, monitor performance, and adjust electrical connections dynamically, enhancing functionality and reducing downtime.

They are built to withstand harsh environments, extreme temperatures, and vibration. They incorporate advanced materials and protective coatings to ensure long-lasting durability and reliable performance.

Advanced Integration with Smart Technologies Wiring harnesses are becoming increasingly integrated with smart technologies such as IoT and AI. This integration enables real-time data monitoring, predictive maintenance, and remote diagnostics, optimising system performance and enabling proactive troubleshooting.

Wiring harnesses will play a crucial role in enabling the seamless integration of advanced technologies such as autonomous driving, connectivity, and advanced driver-assistance systems (ADAS). These harnesses will facilitate the transmission of data, power, and signals between various vehicle components and external systems.

Electrification and Connectivity With the rise of electric vehicles and connected systems, wiring harnesses are designed to handle the increasing power demands and complex connectivity requirements. These harnesses can support higher voltages, accommodate advanced safety features, and enable seamless integration with emerging technologies.

Modular and Scalable Designs To adapt to changing requirements and facilitate efficient manufacturing processes, wiring harnesses are designed with modularity and scalability in mind. This allows for easier customisation, replacement of components, and compatibility with evolving technologies.

Enhanced Safety and Compliance Wiring harnesses prioritise safety and compliance with industry standards and regulations. They incorporate advanced insulation, grounding techniques, and protection mechanisms to ensure electrical integrity and minimise the risk of failures or hazards.

Sustainability and Eco-Friendly Solutions The future of wiring harness design will align with the growing emphasis on sustainability. Harnesses will employ eco-friendly materials, recyclable components, and energy-efficient designs to minimise environmental impact and meet regulatory requirements.

Advanced Manufacturing Techniques The manufacturing processes for wiring harnesses will continue to evolve, incorporating automation, robotics, and advanced assembly techniques. This will improve production efficiency, reduce costs, and enable faster prototyping and customisation.

As we conclude this exploration of wiring harness design, it becomes evident that being future-ready is not just an option but a necessity. The world is witnessing rapid advancements in technology, and wiring harnesses play a pivotal role in facilitating these advancements across industries.

By embracing the trends, you can position yourself as a forward-thinking organisation ready to harness the power of advanced wiring harness design. Stay curious, keep learning, be at the forefront of innovation and drive the future of wiring harness design.