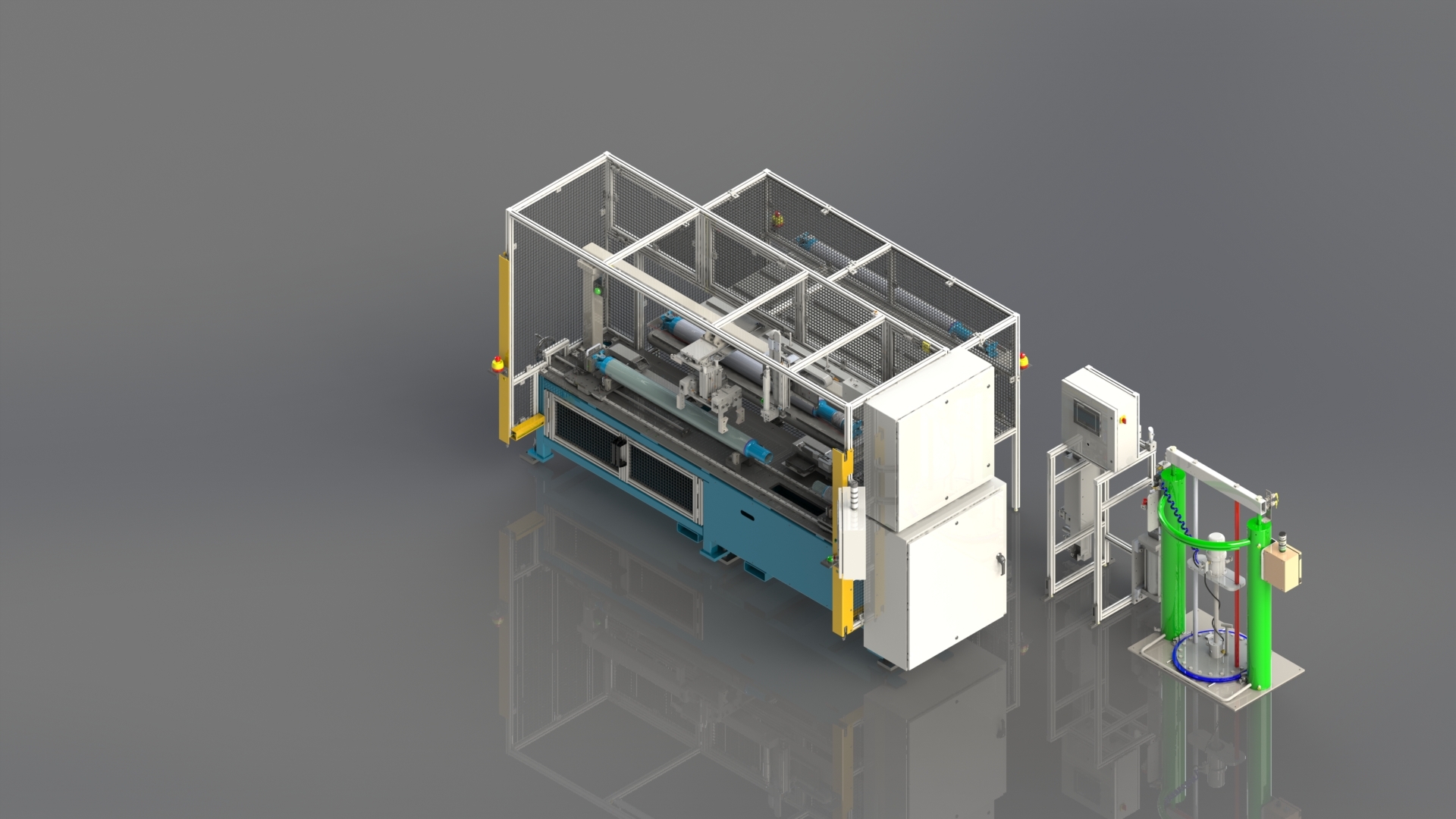

The project involved the comprehensive redesign and optimisation of the Relay Panel Assembly, with a focus on creating a more compact, lightweight, and efficient solution.

The scope included:

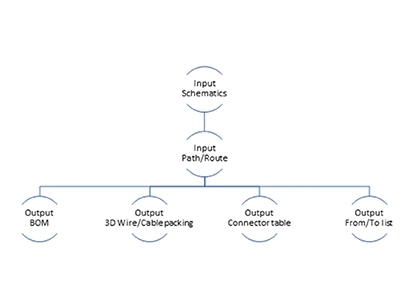

Needs Assessment: Collaborating closely with the client to understand their unique requirements and constraints, ensuring that the new relay panel would meet their specific needs. Design Innovation: Utilising cutting-edge aerospace technology to conceptualise a new, streamlined design incorporating lightweight materials and efficient wiring solutions. Prototyping and Testing: Developing prototypes of the new design and conducting rigorous testing to ensure compliance with safety and performance standards. Manufacturing Optimisation: Simplifying the design to ease production complexity, thereby improving manufacturing efficiency and reducing production time.