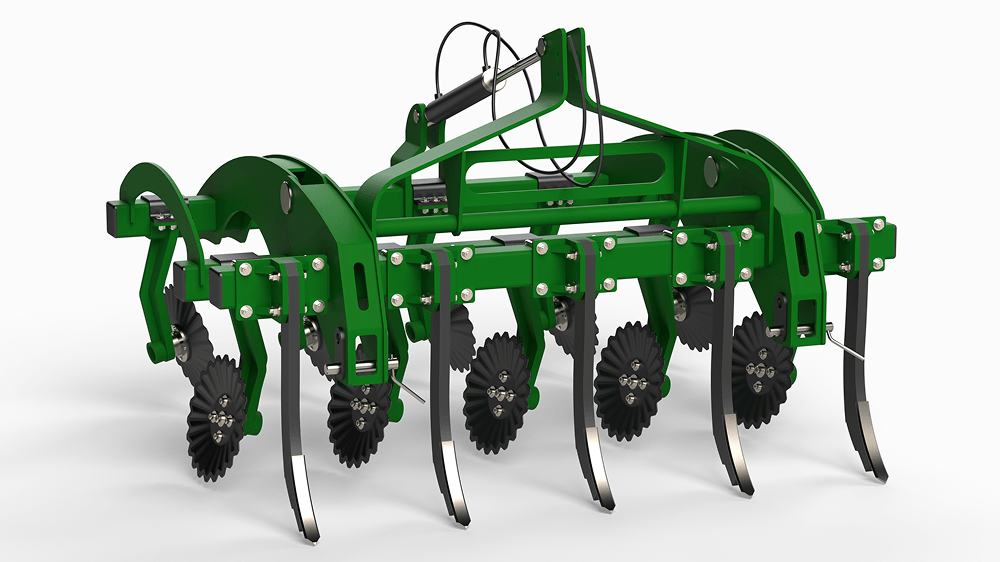

We began by understanding how bale grab attachments are used on skid steer loaders and other equipment in the field, especially in tough Australian farming and construction conditions. The client needed an efficient skid steer attachment that would be reliable, easy to service and simple to manufacture.

1. From Concept to Manufacturing-Ready Design

Our team handled the full product design process in-house. We began by reviewing the concept design provided by the client, aligning it with their performance goals and machine compatibility. From there, we moved into detailed design and 3D CAD modeling, making sure every part and assembly fit together smoothly.

We focused on adjusting the skid steer interface to ensure compatibility with the bale grab attachment, making it easy to integrate and handle bales with a 1800mm diameter.

Once the models of skid steer and bale grab attachment were finalized, we created precise 2D drawings with weld symbols, tolerances, and GD&T (as per ASME Y14.5) to ensure proper alignment. These clear drawings were easy for the client's team to follow.

We also provided a complete Bill of Materials (BOM) and standardized part numbers, simplifying procurement, reducing ordering confusion, and streamlining inventory management.

2. Hydraulic System Integration

A key part of the design was integrating the hydraulic system, including hoses, cylinders, valves and fittings, into a compact layout that allowed smooth movement. We followed ISO 18752 guidelines for hose routing and chose components for easy maintenance and durability.

The client required a 200 mm cylinder stroke length to ensure optimal arm movement. We incorporated this into the design while also adding a mechanical equalizer system to keep both grab arms in sync. This prevented bale slippage and provided stable handling, even at high speeds or on uneven terrain.

3. Material Selection and Compliance

We selected strong, locally available materials to keep manufacturing simple and durable:

⁃ Main structure and arms: Grade 250 mild steel

⁃ Hinge pins: AISI 1045 cold drawn steel for high strength

⁃ Fasteners: High-tensile bolts and Nylock nuts, compliant with AS/NZS 1252, AS 1111.1, and AS 1112.1

These choices made sure the attachment would be durable in the field and easy to build and repair with parts readily available in the Australian market.

4. Designed for Easy Fabrication and Assembly

We applied Design for Manufacturability (DFM) principles throughout the design. That meant using standard profiles, reducing weld complexity and making sure all parts could be assembled quickly without special tools. We also optimized the layout for field servicing, with accessible grease points and removable pins.