We collaborated closely with the client to understand their long-term energy goals, battery vendor preferences, site constraints, and maintenance practices. From there, we created a comprehensive layout and system design that aligned with local codes, future expansion plans and operational needs.

Our product design engineering team led the mechanical side, while our controls engineering experts developed the communication and automation architecture. The result: a fully custom battery energy storage system (BESS) for data center, built to perform, scale and last.

Our comprehensive solution included six key stages:

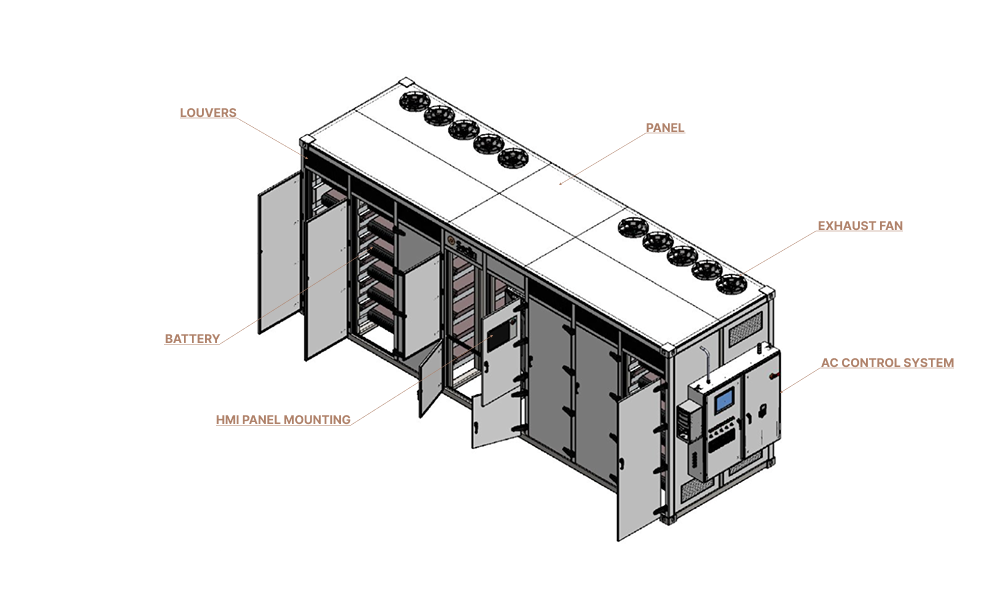

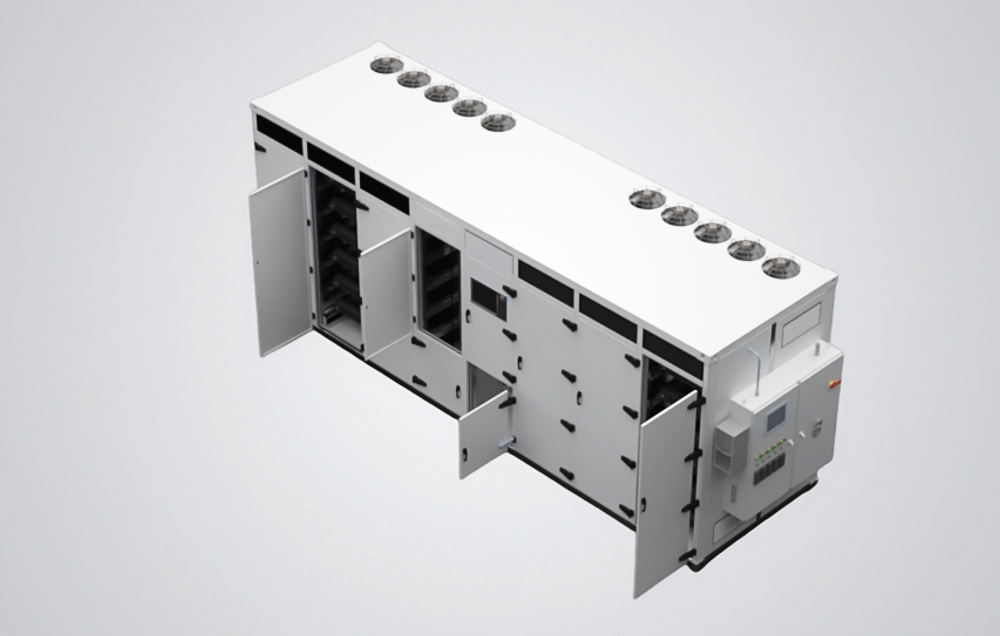

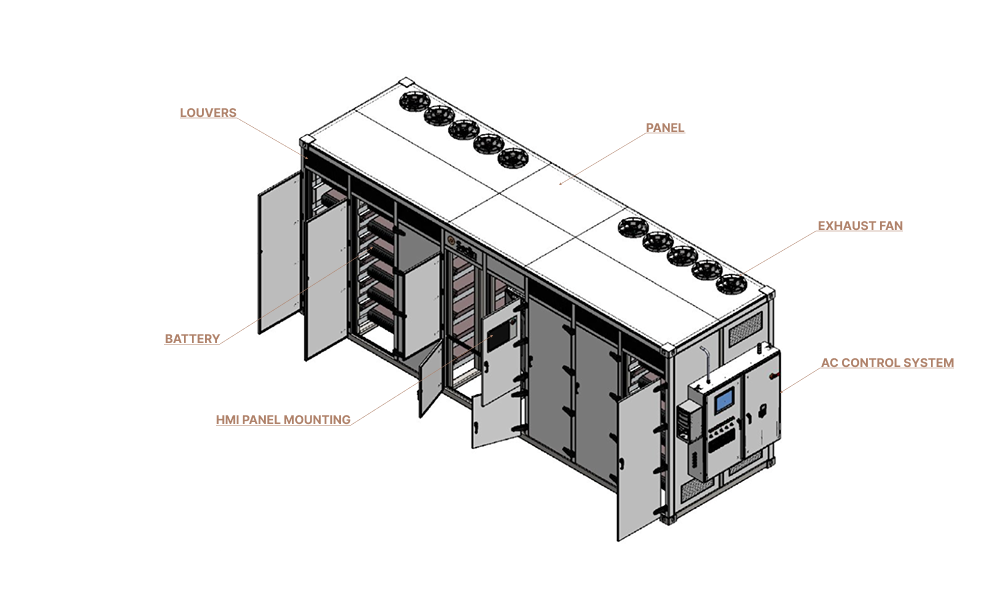

1. Purpose-Built Battery Storage Containers

Unlike standard shipping containers, we designed custom enclosures to safely and efficiently house high-density battery modules. Each container, sized at 25.4 ft × 7 ft × 9.8 ft, delivered 7.5 MWh of energy storage.

With 2-, 4-, and 8-hour discharge options, the client was able to set up deployment to match their data center’s needs. Containers were added or adjusted as per the requirements.

Inside each BESS container:

- Lithium iron phosphate (LFP) battery cells arranged in high-density modules to maximize energy storage capacity.

- Slide-out racks designed for easy maintenance access without disrupting operations.

- DC panels manage power distribution, with cable trays and busbars pre-installed to simplify wiring and minimize mistakes during installation

- Battery Management System (BMS) continuously monitors cell health and ensures operational safety.

- Programmable Logic Controller (PLC) manages container operations and performs diagnostics.

- Compartments divided into fire zones, separating battery modules from inverters and auxiliary equipment to enhance safety.

The containers were modular, skid-mountable, built to withstand harsh environments, and designed to contain fire risks safely.

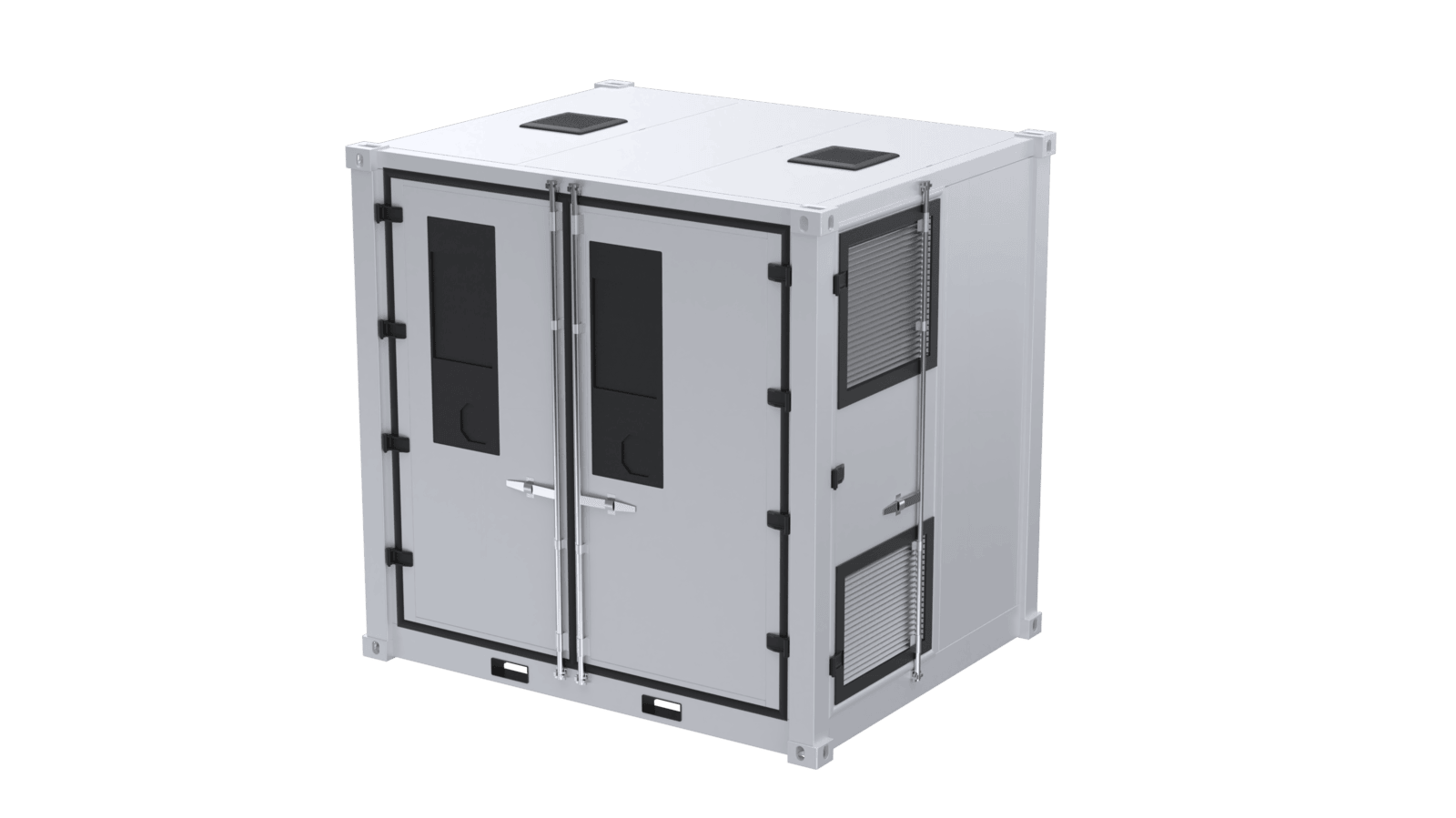

2. Modular Skid Design

Each BESS container was mounted on a rectangular skid, with four containers connected in series on one platform. These modular skids made transport, installation, and future scaling easier.

By arranging multiple skids in series and parallel, the system could be expanded to meet larger energy and power needs without changing the overall layout.

The skids housed advanced control and monitoring systems for real-time diagnostics, predictive maintenance and fast deployment with minimal downtime.

We also designed skids to mount transformers, which streamlined installation and reduced construction time.

3. High-Efficiency Thermal Management

Managing heat was a top priority in the design. We designed airflow paths to ensure consistent cooling across all battery modules inside each container. To maintain safe operating temperatures, we installed:

- Redundant HVAC systems with two-stage air cooling for reliability

- Environmental sensors to monitor temperature, humidity and gas levels

- Passive airflow channels in low-risk compartments to support natural ventilation.

These measures kept the internal temperature safely between 20–30°C, even during high-demand operation or hot weather. If the temperature rises above the safe limit, the system triggers alerts to allow a quick response.

Additionally, sufficient spacing was maintained between containers and skids to promote airflow and prevent heat buildup, ensuring efficient cooling throughout the entire system.

4. Built-In Safety Features

Safety was a key focus throughout the design. Our system was built to meet and exceed industry standards like UL 9540, UL 9540A, relevant IEC codes and more.

Each container was equipped with:

- Smoke detectors and thermal sensors strategically placed for early hazard detection

- Clean agent fire suppression systems pre-installed in critical zones

- A fire alarm system that triggers an external horn, strobe light and fast-stop shutdown

- Deflagration panels and fast-stop mechanisms to manage thermal and gas events swiftly

We integrated continuous monitoring to detect anomalies early and alert operators, ensuring 24/7 operational safety.

5. Smart Control Systems

Our controls team developed a robust system that gave the client full visibility and command of their storage operation. This included:

- Real-time monitoring of State of Charge (SoC), battery health, temperature and current

- Integration with local grid control systems via Modbus and IEC standards.

- Automated charge/discharge scheduling

- Predictive maintenance alerts tied to key hardware performance metrics

A custom dashboard allowed both plant operators and utility partners to view status and issue commands from anywhere, securely.

6. Designed for Easy Installation and Maintenance

From day one, we designed the system for quick and hassle-free installation. Modular skids and pre-integrated components meant less on-site assembly and faster setup. This approach reduced installation time and minimized errors.

Both the enclosures and skids were built with structural integrity in mind, designed to withstand harsh weather conditions without compromising safety or performance.

We also prioritized long-term serviceability. Every component, from battery racks to cooling units, was placed for easy access and minimal disruption during maintenance.

The final design included:

- Walk-in access with safe working clearances for technicians

- Removable panels and neatly routed cabling for quick servicing

To further support field teams, we provided:

- Comprehensive service and installation manuals

- A full inventory of critical spare parts

This approach ensured the system remained efficient, durable, and easy to maintain throughout its lifecycle.