The project aimed to build an automated MIG welding cell for door reinforcement structures, ensuring high-quality welds that meet industry and customer standards. The solution required a fixture to securely hold BIW components, allowing precise alignment, accommodating various geometries, and improving welding efficiency.

Welding Automation

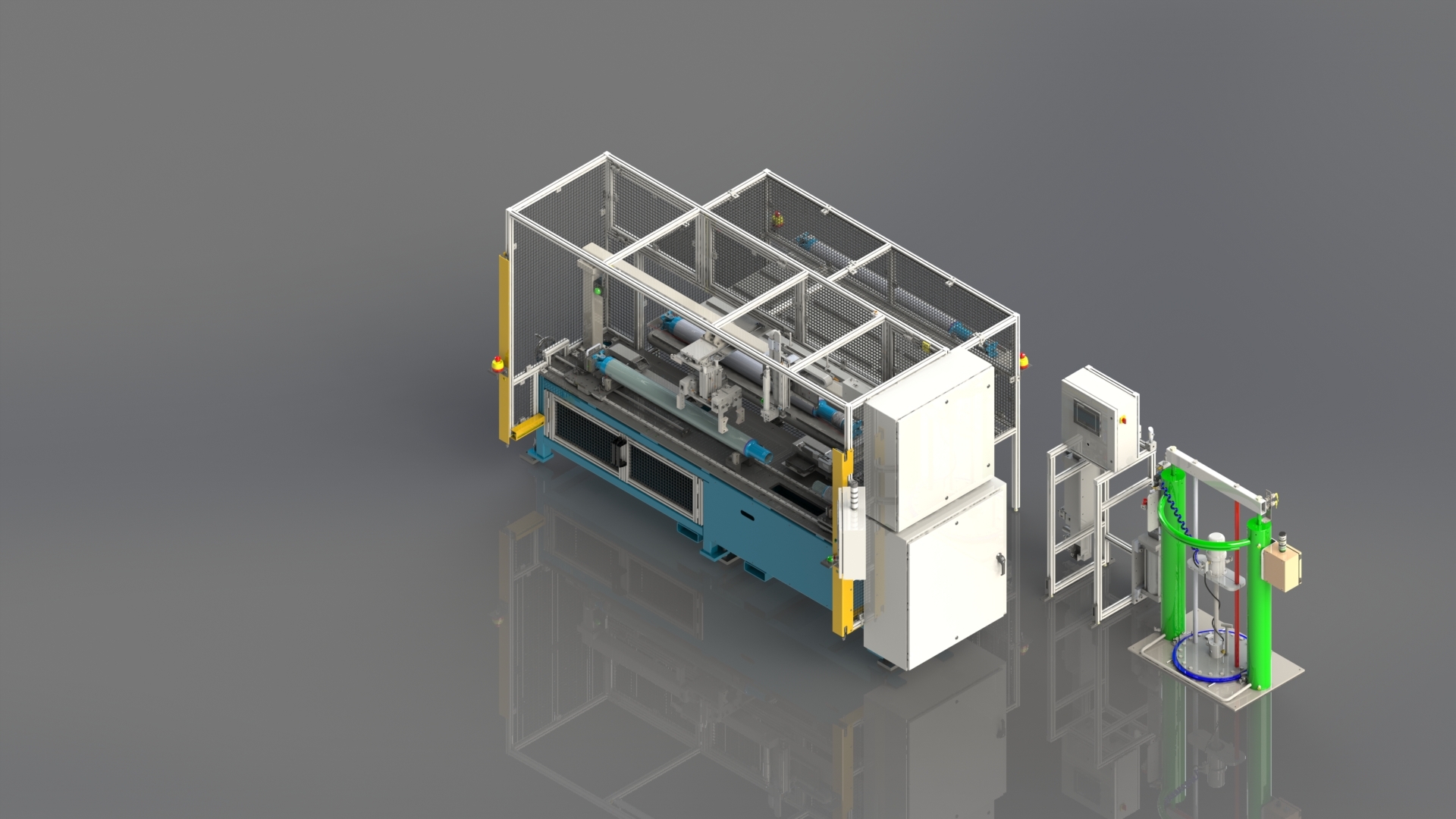

Automated MIG Welding Cell Design

The customer is a Tier-1 supplier to a major automotive company with a global presence, specializing in the development of Body-In-White (BIW) reinforcement and structural parts.

Scope

Challenge

- The complex geometry of the door reinforcement structures posed challenges in achieving precise welds in hard-to-reach areas, crucial for safety and structural integrity.

- Maintaining consistent weld quality across high volumes was critical to meet stringent client standards.

- The fixture needed to support both front and rear door parts, withstand continuous operation, and minimise maintenance downtime.

- Reducing cycle times while increasing throughput without sacrificing quality was a priority, especially for welding on multiple orientations of the reinforcement structure.

Solution

An advanced automated MIG welding cell was introduced to tackle the outlined challenges:

- A durable fixture was crafted to secure various door reinforcement structures, designed to handle slight size and geometry variations. Precise locating and clamping units ensured stability and accuracy during welding.

- A common, compact base was included to align both front and rear door parts correctly, with specific clamp units for each component.

- The fixture was mounted on a rotary frame, allowing for indexed positioning at optimal angles for welding the reinforcement structure’s pipe and its sub-components.

- Quick-release mechanisms facilitated rapid loading and unloading, cutting cycle times and enhancing throughput.

- The unit featured a chip/spatter collection tray to maintain cleanliness and operational efficiency.

- Inline quality monitoring systems were integrated to ensure welds consistently met quality standards, providing immediate feedback and rejecting components that did not comply.

- Safety measures, such as protective enclosures, safety shutters, and emergency stop buttons, were integrated, along with ergonomic enhancements for operator ease during loading and unloading.

- The fixture used heat-resistant materials to withstand arc welding temperatures, and comprehensive safety barriers ensured compliance with regulations.

- The design incorporated DFMEA principles to address potential failure modes, ensuring a robust, uninterrupted operation that significantly boosted productivity.

Value and Benefits

The tailored MIG welding cell delivered superior results, achieving precise positioning and high-quality welds for door reinforcement structures.

Quick-release mechanisms and ergonomic designs reduced cycle times, enhancing efficiency and helping the customer meet production targets.

Advanced welding technology paired with real-time quality monitoring minimised defects and rework, while the fixture’s adaptability allowed for future production adjustments.

Sedin's innovative approach ensured the welding cell not only met current demands but also set the stage for the customer's future growth in the automotive sector.