Leveraging their structural design and detailing expertise, our team conducted in-depth research and engineering analysis to develop a structurally sound, efficient, and fabrication-ready pedestrian bridge design. The goal was to ensure strength, durability, and ease of manufacturing, all while meeting industry standards.

Our solution included:

1. Material Selection

Our team carefully analyzed materials to ensure the bridge could withstand all weather conditions. We chose corrosion-resistant steels like ASTM A709 Grade 50W and A588, which provided an optimal balance of strength (345 MPa yield) and weight.

These materials enhance the bridge's structural durability in high humidity and extreme temperatures, ensuring long-term performance without additional coatings.

2. Structural Design and Analysis

We studied pedestrian traffic patterns, environmental loads, and material behavior to ensure the bridge could handle live loads, wind, and seismic forces with minimal deflection and vibration. The design followed AASHTO LRFD and AISC standards for safety and reliability.

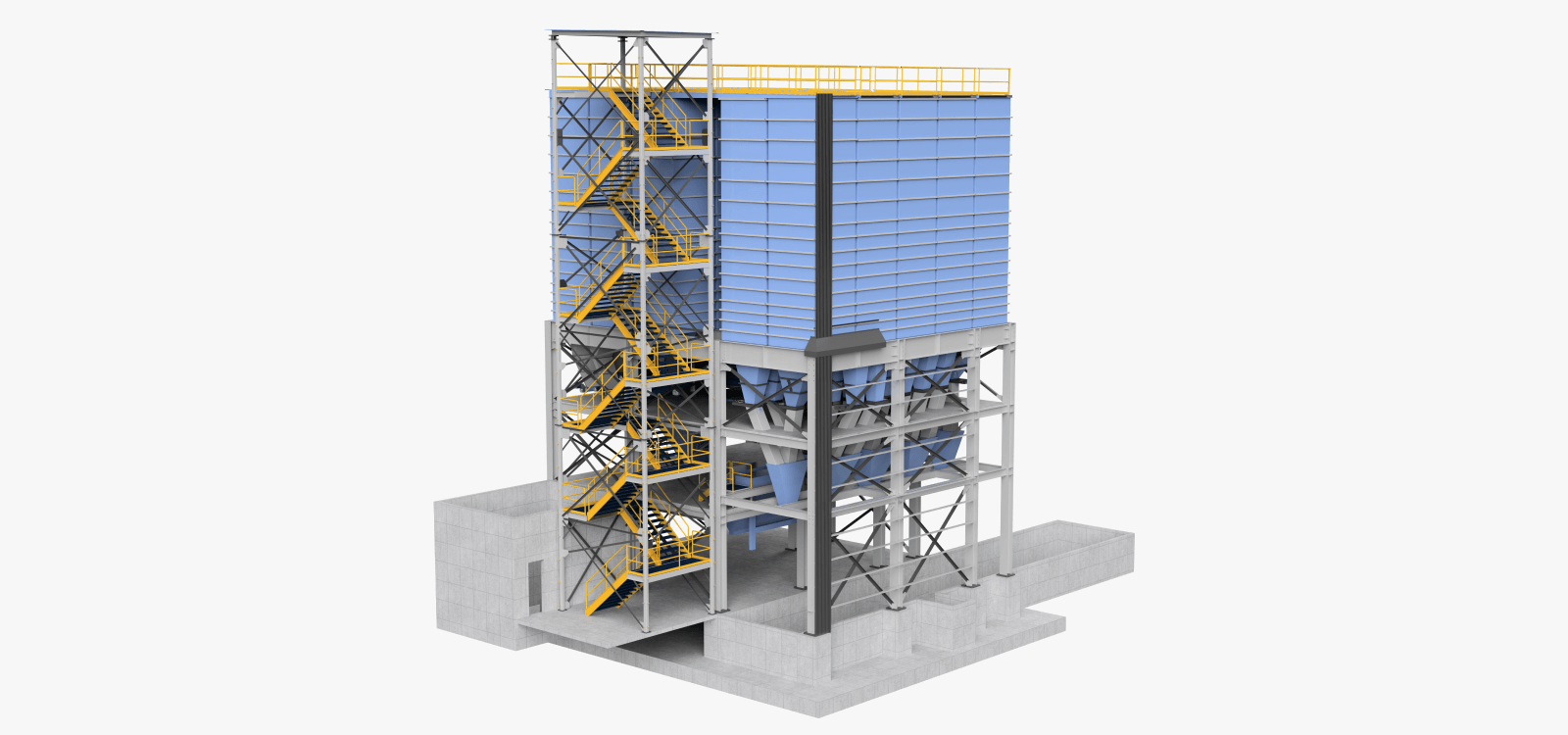

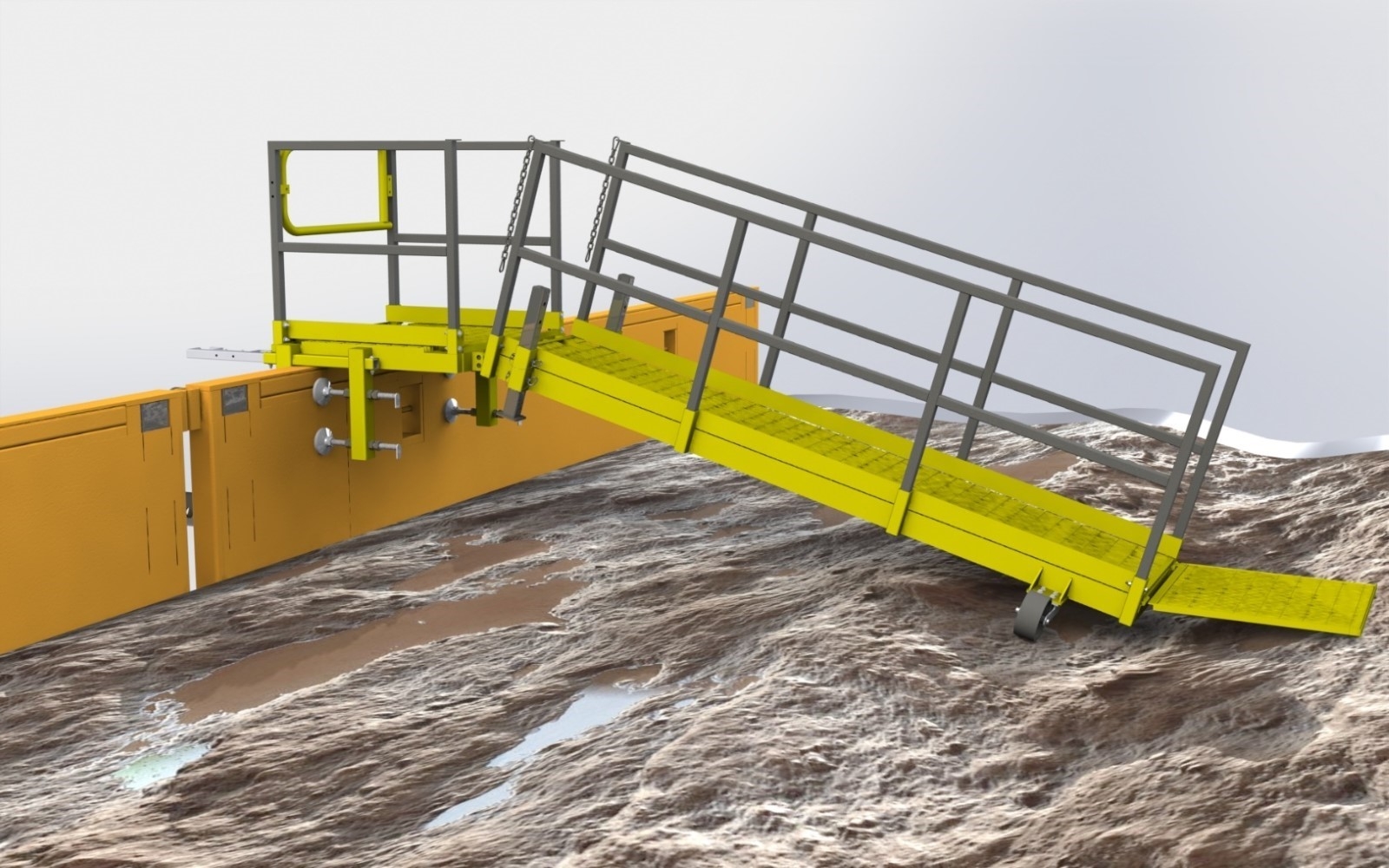

3. 3D Modeling & Detailing

Using Tekla Structures, we created highly detailed 3D models and fabrication drawings of the bridge, detailing frames, beams, braces, connections, and fasteners. This provided the client with clear, accurate information to minimize errors and speed up the production process.

4. Optimized Fabrication & Installation

We designed modular sections that simplified manufacturing and transportation. Using DFMA (Design for Manufacturing and Assembly) and DFMEA (Design Failure Mode and Effects Analysis), we ensured the bridge could be fabricated with minimal welding and installed quickly on-site.

Additionally, we provided a clear erection sequence to simplify material handling and assembly on-site.

5. Coating & Assembly Considerations

Our detailing included information about protective coatings to prevent corrosion, assembly and erection plans, and an efficient assembly process to cut down on labor and installation time. The design ensured the bridge could withstand all weather conditions.

Our final deliverables included detailed 3D models, fabrication drawings, and material specifications to support manufacturing and installation. We also provided shipping, and erection plans to ensure smooth on-site assembly.