Is outdated packaging slowing your delivery times?

Manual packing, frequent errors, and slow line adjustments can kill your productivity. And if you're struggling to keep up with demand, you're not alone.

Manufacturers today are under pressure to pack faster, handle more product types, and keep costs low.

That’s where automated packaging systems come in.

They seal, label, sort, and palletize, quickly and accurately. You get more done with fewer hands and less hassle.

In this blog, you’ll learn how packaging automation works, what benefits it brings, and how to get started. If you're in manufacturing and want a more efficient line, keep reading.

What are Automated Packaging Systems?

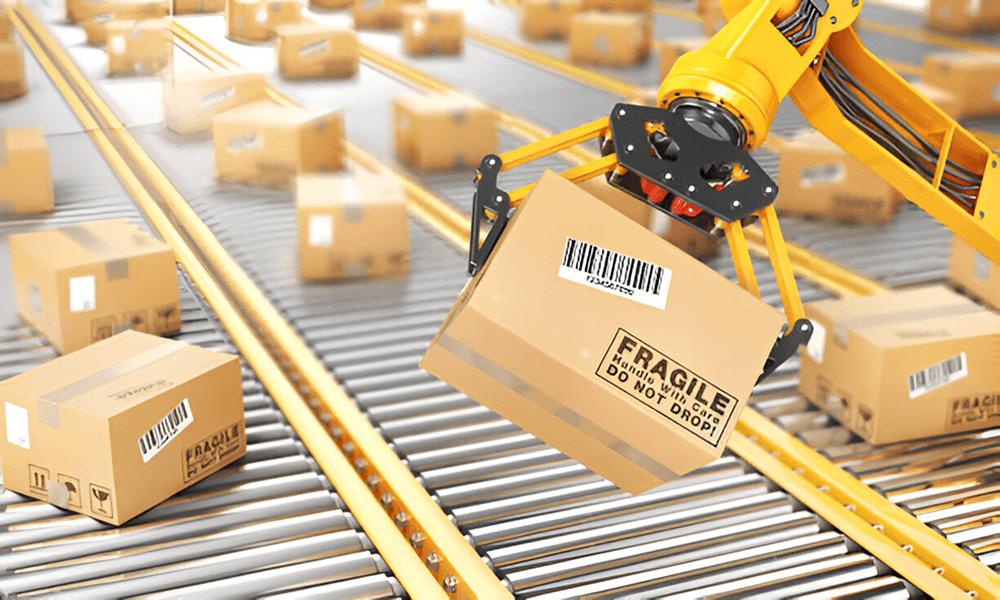

Automated packaging systems are machines that handle the packaging process with little or no human input. They can automatically fill, seal, label, wrap and palletize products, making packaging faster, more consistent, and less labour-intensive.

These systems are often used in manufacturing plants, warehouses, and distribution centers. They’re built to handle everything from food and beverages to pharmaceutical products and industrial parts.

Common Types of Automated Packaging Systems

Automated packaging systems can be grouped based on the stage they support in the packaging process:

1. Primary Packaging

These machines come into direct contact with the product and place it into its first layer of packaging, commonly used in food and beverage automation. Common examples include:

- Filling machines (liquids, powders, solids)

- Capping or sealing machines

- Flow wrappers and vacuum sealers

2. Secondary Packaging

Once the product is packed, these systems prepare it for grouping, identification, and protection:

- Cartoners and case packers

- Labeling and coding machines

- Vision inspection, checkweighers and metal detectors

3. End-of-Line Automation

These systems finalize the packaging for shipping and storage:

- Robotic or layer palletizers

- Stretch wrapping or banding machines

- Conveyors or AGVs for product movement

The Need of Automated Packaging Systems Across Different Industries

Manual packaging takes time, costs more and often leads to mistakes or inconsistent quality. As demand increases and skilled labour becomes harder to find, manufacturers across industries are facing growing pressure to improve their packaging operations.

Here’s what different industries are dealing with:

- F&B manufacturers need to handle short shelf lives, strict hygiene standards, and fast-moving production lines. Manual processes slow them down and increase the risk of contamination or product waste.

- Pharmaceutical companies must meet precise dosing, labeling and traceability standards. Human error in packaging can lead to compliance issues or safety risks.

- Logistics and warehousing teams struggle with high order volumes, late shipments and packaging inconsistencies. Manual packaging can’t keep up with fast shipping demands and frequent product changes.

- General manufacturing companies face rising labor costs and growing product complexity. Manual processes slow things down and cause delays on the shop floor.

In all these sectors, the need is clear: faster, more reliable and scalable packaging processes. That’s what’s driving the shift toward automation.

How Packaging Automation Works

Packaging automation replaces manual tasks with machines that handle everything from product sorting and filling to sealing, labeling, and palletizing.

It starts with sensors and conveyors that move items through each stage. Depending on your setup, robots, vision systems and PLCs control the flow and quality, ensuring accurate, repeatable results.

Whether it’s semi-automatic or fully automated, the goal is the same: faster packaging with fewer errors and less labor.

Benefits of Packaging Automation

As manufacturing becomes faster and more complex, packaging automation offers a strategic advantage over manually picking. Here are some key advantages that make automated packaging systems essential for manufacturers today:

1. Increased Speed and Efficiency

Automated systems can run 24/7, handling high volumes with minimal downtime. What might take a team hours to pack can now be done in minutes. You get more output without needing to hire more people. That makes it easier to hit tight deadlines, keep up during peak seasons and scale up as demand grows.

For instance, automated food packaging systems can package thousands of units per hour without needing to add shifts or extra workers.

2. Consistent Quality and Fewer Errors

Machines don’t get tired or distracted. Automated packaging ensures that every box is sealed correctly, every label is in place and every unit is packed according to the requirements. And the result? Less waste, fewer product returns, and a better customer experience.

This is especially critical in pharma, where mislabeling or dosage errors can have serious consequences.

3. Lower Operating Costs

Automation in packaging industry may require a higher upfront investment. But it saves money in the long run by cutting labor, rework and waste. For high-volume work, the savings add up fast.

In logistics, automated packaging systems handle everything from boxing to labeling without needing manual steps in between. That means fewer hands on each order, less room for error, and much faster fulfillment.

4. Better Compliance and Traceability

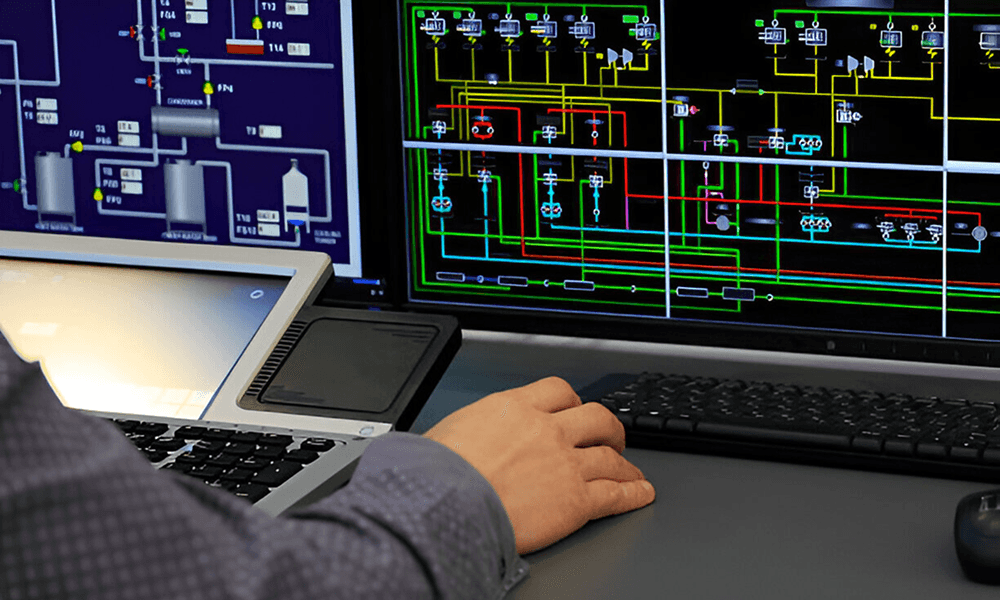

Automated systems can integrate with MES, ERP, or labeling systems to ensure regulatory compliance. This is essential in sectors like pharma and F&B, where every unit must be traceable and meet strict packaging standards.

With built-in barcode scanning and product codes, it’s easy to track every item at every stage. No manual checks needed.

5. Improved Workplace Safety

Repetitive tasks like lifting, taping, and sealing are major causes of injury in manual packaging lines. Automation reduces strain on workers and lowers the risk of accidents, especially in fast-paced or hazardous environments.

6. Flexibility for Mixed or Custom Packaging

Modern packaging systems can quickly switch between different products, sizes, or packaging styles. That means less time wasted on setup and more flexibility. This helps manufacturers and logistics teams handle different types of products, effortlessly.

7. Data and Insights for Optimization

Automated packaging machines can provide real-time data on output, downtime and defects.

How many items were packed today? Which machine had the most downtime? Where are packaging errors happening? Are we meeting our production targets? You can get answers to all these questions with built-in sensors, barcode scanners and connected software, all working together in real time.

8. Faster Time-to-Market

With automated systems, you can reduce packaging lead times and respond faster to market changes, promotions or new product launches. This kind of flexibility helps you stay ahead of the competition.

Future Trends in Packaging Automation

With the rise of industrial automation applications across different sectors, packaging systems are also evolving to become smarter, faster and more flexible. Here’s what to expect in the near future:

- More use of cobots: Collaborative robots are showing up more on the packaging line. They're safer to work around, easier to program and perfect for tasks like case packing, labeling or palletizing, especially when space is tight.

- AI and machine learning: These tools help systems learn from data, like spotting defects early, predicting maintenance needs, or adjusting settings automatically to reduce waste.

- Easy changeovers: Future packaging machines are being designed to switch quickly between different products, box sizes or materials. That means less downtime and more flexibility. Perfect for those who deal with short production runs or fast-changing product lines.

- Connected systems (IIoT): New automated packaging machine will have built-in sensors and data tracking. This means you’ll know exactly how each machine is performing, real-time data on speed, output, errors and downtime.

- Sustainable packaging: More machines will be designed to handle eco-friendly materials, like recyclable films or compostable trays, without slowing down the line or increasing defects.

How to Get Started with Packaging Automation?

Want to automate your packaging but not sure where to start? Here's a simple path forward:

1. Look at your current process

Break down each step: filling, sealing, labeling, boxing. Where are the delays? Where are workers doing the same thing over and over?

2. Find what’s slowing you down

Are changeovers taking too long? Are errors common? Is labor cost too high? Start with the area that’s causing the most trouble.

3. Start small if needed

You don’t have to automate everything at once. Begin with one part, like a case packer or labeler and build from there.

4. Talk to the right experts

Work with an automation team that understands manufacturing. They’ll help you choose the right machines based on your products, space and budget.

5. Train your team

Make sure your team knows how to use and care for the new equipment. The better the training, the smoother the results.

Need expert help to automate your packaging systems?

Sedin Engineering offers end-to-end industrial automation solutions for different applications like packaging, assembly lines, welding, testing, special-purpose machines, and more.

Let’s discuss how we can make your line faster, more efficient and cost-effective. Contact us today.