If you work in automotive manufacturing, you know one thing for sure: the industry is changing fast. Electric vehicles (EVs), stricter quality demands, labour shortages and the push for sustainability are changing the way cars are made.

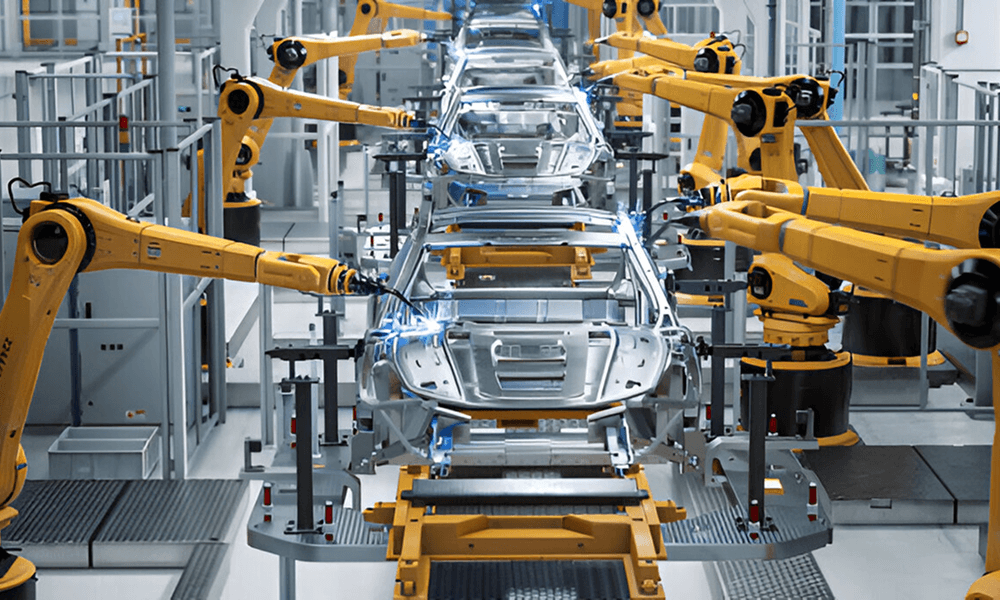

To keep up with these changes, manufacturers are turning to automation. It’s playing a key role in helping automotive plants stay competitive, improve efficiency, minimize errors and consistently meet strict quality standards.

In this article, we’ll walk through how automation is impacting the automotive industry, the unique challenges that come across, what technologies are leading the way and the real financial benefits you can expect.

If you are a plant manager, engineer or executive looking to integrate industrial automation services into your automotive plant, this is your practical guide.

Why Automotive Automation Isn’t Optional Anymore

According to the International Federation of Robotics, the automotive sector is using more industrial robots than any other industry worldwide. This shows how deeply automation is woven into every part of automotive manufacturing: from BiW welding and painting to parts assembly and final inspection.

Did you know? BMW now automates 95% of its body-in-white production. This allows the company to efficiently produce both internal combustion engine (ICE) and electric vehicle (EV) models on the same assembly line, without the need to rebuild their entire plant.

The move to industrial automation is driven by several powerful forces:

- The rise of electric vehicles: EVs require new production lines with flexible setups because battery packs and electric drivetrains differ greatly from traditional engines. Automation allows rapid reconfiguration without expensive downtime.

- Complex product variations: Many manufacturers now produce multiple variants on the same line. Different models, trims or even custom features. Manual processes struggle to maintain quality and speed here, but automation keeps things running smoothly.

- Labor shortages: The manufacturing sector faces a growing gap in skilled workers. According to Deloitte, over 2 million manufacturing jobs in the US alone may go unfilled by 2030. Automation helps fill that gap and reduces reliance on scarce labor.

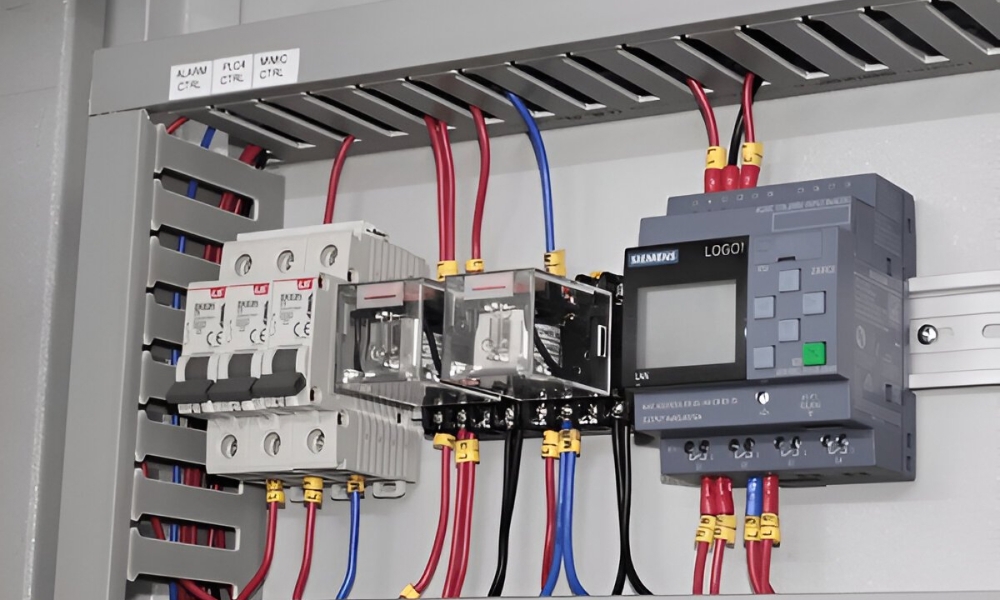

- Legacy systems: Many plants still rely on older equipment and PLCs (programmable logic controllers) that aren’t designed for today’s connected factory demands. Integrating new automation technologies with these legacy systems is a key challenge.

- Meeting quality standards: Automotive manufacturing requires strict compliance with standards like IATF 16949, which demands thorough traceability, documentation and process controls. Automation systems make it easy to consistently meet such requirements.

- Market competitiveness: Automation is now what sets automotive manufacturers apart. As product cycles shorten and customization increases, companies rely on smart automation to adapt quickly, maintain quality and control costs. Staying competitive today means having connected, flexible automated systems.

The Top Automation Trends Transforming Automotive Plants in 2025

What technologies are shaping this transformation? Here are six major automation trends:

1. Collaborative Robots (Cobots)

Unlike robots in automotive industry, cobots can safely work alongside human operators. They take on repetitive or physically demanding tasks like welding and material handling. This not just improves worker safety and reduces fatigue but also helps manufacturers manage labor shortages without losing productivity.

2. Edge Computing PLCs

In automotive manufacturing, fast decision-making is crucial. Edge computing PLCs analyze data locally at the machine level, enabling immediate detection of faults and faster responses. This helps with predictive maintenance and keeps downtime low. This technology is especially useful when plants are manufacturing both electric and combustion engine vehicles.

3. Modular and Integrated SCADA Systems

Modern automotive plants involve complex operations that require seamless coordination. Today’s SCADA systems are flexible and connect easily with systems like MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning). This gives managers real-time visibility, allowing them to spot issues quickly and keep production on track.

4. Advanced Human-Machine Interfaces (HMIs)

User-friendly HMIs have become essential in automotive manufacturing. Intuitive touchscreens and clear displays reduce operator errors and shorten training time. This leads to more consistent product quality and less production downtime, meeting the high standards demanded in the industry.

5. Robotic Simulation and Offline Programming

Stopping the entire production line to implement changes can be costly. Robotic simulation lets engineers create and test robot tasks in a virtual environment. Offline programming allows these tasks to be updated without halting the automotive assembly line, helping plants adapt quickly to changes.

6. Energy-Efficient Automation

Energy consumption is a major concern for manufacturers aiming to reduce costs and meet sustainability goals. Automation systems designed for energy efficiency help lower power consumption without compromising performance. This helps achieve both environmental and financial goals.

Avoiding Common Challenges: How to Ensure Your Automotive Automation Project Succeeds

Automation in the automotive industry brings big opportunities, but also real challenges. From outdated systems to training gaps, here are 6 key areas to focus on:

1. Upgrading legacy systems

Most plants still run on older PLCs and equipment. Replacing or retrofitting them isn’t always simple — and doing it without a solid plan can lead to costly downtime. Think ahead, and map out how new automation will fit into your current setup.

2. Getting your systems to talk

Your SCADA, MES, and ERP platforms need to share data seamlessly. If they don’t, you’ll end up with delays, bad data or missed issues. Choosing systems that work well together is key to smooth operations and better decision-making.

3. Training your team

New technology only works if your people know how to use it. Make sure operators, technicians and engineers get proper training. This builds confidence and helps you get the most out of your automation investment.

4. Protecting against cyber threats

Automation brings a lot of connected devices. And that means more risk. Protect both your IP and production uptime with layered, built-in security from the start.

5. Staying flexible

Avoid getting locked into one vendor. Open, modular systems let you grow and change as needed without being stuck with one supplier’s rules or pricing.

6. Considering outsourcing

Not every company has the time or team to handle everything in-house. Partnering with a trusted industrial automation service provider for mechanical design, controls engineering or system integration can speed up your project and reduce risk.

The Real ROI of Automation: What You Can Expect Financially

Automation is a smart investment. Here are some common benefits observed by automobile manufacturers:

- Reduced downtime: Plants report up to 27% less downtime after upgrading SCADA systems and introducing predictive maintenance.

- Improved efficiency: Overall Equipment Effectiveness (OEE) often increases by 20% or more with modern PLCs and robotics.

- Lower scrap rates: Automated inspections and vision systems reduce scrap by 30-35%, saving material costs and rework time.

According to Mitsubishi Solutions, manufacturers often experience a 40% ROI on automation investments, thanks to lower labor costs and increased efficiency.

Note: OEE (Overall Equipment Effectiveness) shows how well equipment performs. It’s calculated by multiplying three factors: Availability, Performance and Quality.

Sustainability: How Automation Supports Green Manufacturing

Beyond cost savings, automation helps automobile manufacturing plants reduce their environmental footprint. Here’s how:

- Shorter machine cycles help cut down on energy use and reduce waste.

- Higher first-pass yields mean fewer defective parts, which leads to less scrap ending up in landfills.

- Improved material tracking makes it easier to support reuse and recycling — key for circular economy efforts.

Many OEMs now include sustainability metrics in their automation KPIs, showing that efficiency and environmental responsibility can go hand in hand.

How Sedin Engineering Team Helps You Win

We understand the challenges of automotive manufacturing. Our automation services help you improve efficiency, cut downtime and keep production running smoothly.

Over the past 10 years, our team has worked across multiple industries, including automotive and knows what it takes to deliver results. Our solutions include

- Mechanical design for conveyors, fixtures and robot tooling to fit your exact process.

- PLC programming for Siemens, Rockwell, Omron and other platforms. Our code is optimized for speed, reliability and safety.

- SCADA development that connects with your MES and ERP systems, giving you real-time plant-wide visibility and control.

- User-friendly HMI design that reduces training time and operator errors.

- Robotics simulation and offline programming to test layouts and paths virtually. This helps you avoid expensive rework on the shop floor.

- Control panel and hardware design engineered for clean integration, easy installation and long-term reliability.

If you're looking to upgrade a line or automate your entire plant, we’re ready to support you with proven engineering expertise.

Further Reading: Optimize Battery Assembly Lines with Smart Design and Automation

Ready to Improve Your Automotive Plant’s Efficiency with Smart Automation?

Start by automating a single production line, upgrading control systems or testing with robot simulations. These steps will help you improve efficiency and reduce downtime without major disruptions.

Ready to see how automation can transform your manufacturing? Book a consultation with our senior engineers. We’ll assess your systems and recommend practical steps to increase ROI and keep you competitive.

Let’s take your automotive automation to the next level.