Rising production costs, shrinking margins, and strict quality demands—manufacturers today face more pressure than ever. Add tight deadlines and complex regulations, and delays feel almost inevitable. With all these challenges, new product development has gotten a lot more complicated.

However, with the right approach, such obstacles can turn into opportunities for innovation and growth.

In this blog, we’ll guide you through the new product development process, the challenges you may face, and practical strategies to overcome them—ensuring your product gets to market faster and more efficiently.

Do you have a new product concept or an existing product that needs to be designed into reality? Claim Sedin’s Product Design Engineering Service today!

What is New Product Development?

New Product Development (NPD) is the journey of turning a new idea into a product ready for the market. It’s all about creating products that are:

- Feasible and efficient

- Cost-effective

- Easy to manufacture

- Quick to market

- Compliant with industry standards

- Optimized for minimal waste

- Tested for potential risks

The goal of NPD is to deliver a product that solves a problem, is efficiently designed, and meets market needs. And with the right process, you can ensure your product is successful from concept to completion.

New Product Development Process

The New Product Development (NPD) process involves several key stages that ensure the final product meets the consumer demands and performance standards.

1. Requirements Definition

This stage involves creating a detailed list of functional and performance requirements based on resource availability and market research. It ensures that the product meets user needs, regulatory standards, and quality expectations, providing a clear foundation for design.

2. Product Design Conception

A product concept is a clear idea or vision of what a product will be, including its purpose, target audience, and key features. This stage of the new product development process involves defining the vision for the product and brainstorming ideas to address market needs.

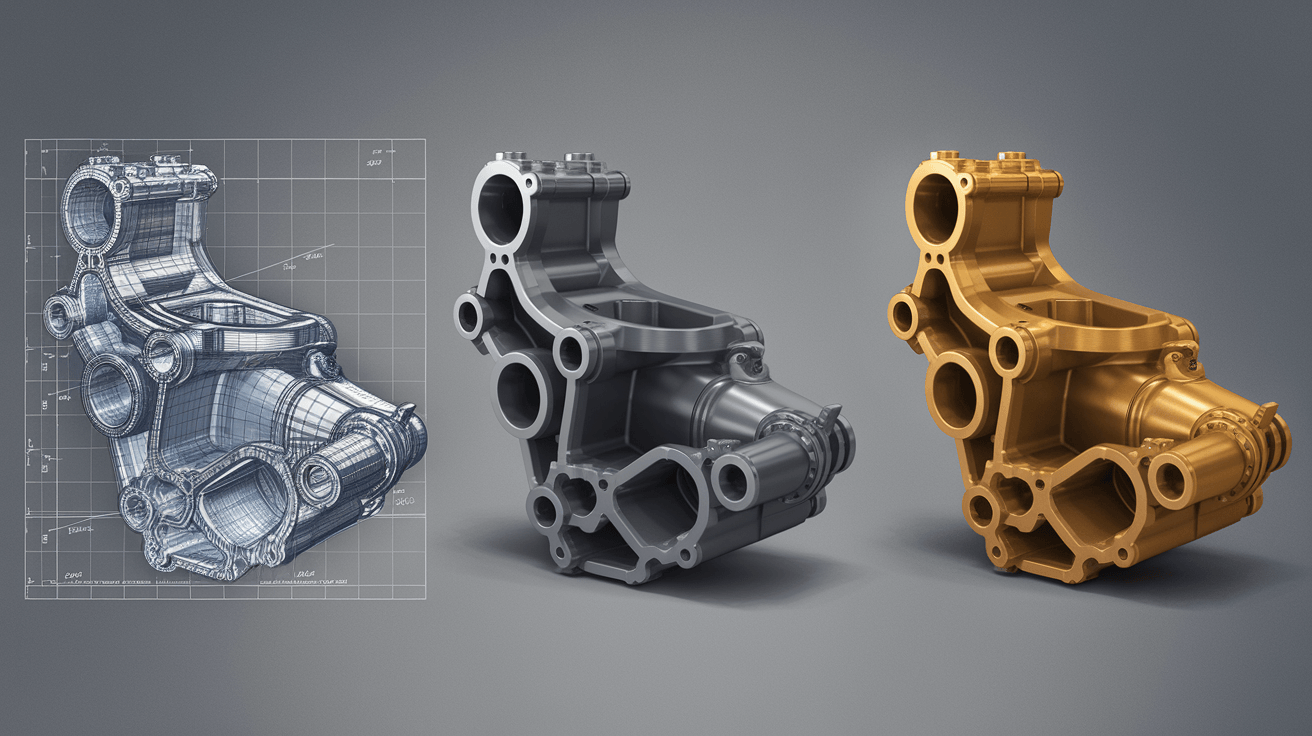

In this phase, the design engineers develop the initial design through simple sketches. These concepts visually represent the product, enabling early feedback and idea refinement to align with user expectations.

3. Detailed Design

This stage involves creating detailed designs through CAD modeling. It includes specifications for materials, dimensions, and assembly processes, laying the groundwork for production.

Design for Manufacturability (DFM) and Design Failure Mode and Effects Analysis (DFMEA) are applied to identify potential risks early and ensure easy manufacturing. This helps make production more efficient and cost-effective.

4. Design Iterations & Validation

This stage focuses on finalizing the design while keeping manufacturing costs and budget in mind. The design is optimized for production by considering material choice, manufacturing processes, and assembly efficiency.

It also includes validating the design to ensure it meets all functionality, manufacturability requirements and industry standards.

5. Prototype Testing

While validation ensures the design meets the desired requirements, hands-on testing is essential. A prototype is built to test the design in real-world conditions, helping to spot any issues with functionality, design, or usability.

Based on feedback, engineers refine the design, ensuring it meets quality, safety, and regulatory standards before moving into full-scale manufacturing.

6. Manufacturing

This final stage focuses on preparing for full-scale production. The product is tested for manufacturability, and supply chains, vendors, and assembly lines are set up.

Before the market launch, the product is thoroughly tested to make sure it meets all performance standards, ensuring a smooth introduction to consumers.

Key Challenges in New Product Development

A new product design and development comes with challenges, from managing costs and timelines to navigating technical issues and regulations. Addressing these early is crucial for success.

Here are key challenges to tackle before entering the design phase.

Balancing Quality and Costs

One of the most significant challenges in new product development strategy is balancing quality with cost-efficiency. Achieving the perfect balance between high-quality output and staying within budget can be difficult.

Handling Complex Regulations

Every industry has its own set of regulations that products must adhere to. Navigating these regulations can seem daunting, especially when working across multiple regions with different standards. Manufacturers need a solid understanding of these requirements from the start to ensure that the product remains compliant.

Accelerating Time-to-Market

In manufacturing, time-to-market is critical. The longer it takes to launch a product, the higher the risk of losing your competitive edge. Speeding up the development process requires not just efficient design, but also testing, validation, and refinement at each stage.

How to Overcome Challenges in NPD: A Practical Approach

To tackle these challenges effectively, you need a clear, step-by-step approach that covers every phase of the new product development cycle, including:

Market Research

Before designing a new product, it’s essential to conduct thorough market research. Understanding customer needs, preferences, and current trends helps to ensure the product will meet market demands.

Pro-tip: Conduct in-depth research to gain valuable insights into your competitors, uncover market gaps, and identify opportunities that can make your product stand out.

Feasibility Analysis

Not all ideas that sound great are feasible. A solid feasibility analysis is crucial for determining whether your product idea is technically viable and financially sustainable.

By analyzing the technical, financial, and operational aspects of the project the project from the start, you can avoid wasting resources on ideas that might not work.

Collaborative Design Process

The design process should be a collaborative effort. Using modern CAD tools, you can create accurate digital prototypes that enable detailed evaluation and collaboration across teams.

The iterative design process allows for early identification of potential issues, reducing costly revisions later on.

Design for Manufacturability

A well-designed product is one that can be easily manufactured at scale. This involves choosing the right materials, understanding the production capabilities of suppliers, and simplifying assembly processes where possible.

Design for manufacturing ensures that the product is not only high quality but also cost-effective to produce.

Risk Mitigation through Testing

Testing and validation are key to spotting potential issues early. Advanced simulations and prototype testing show how the product will perform in real-world conditions. This helps designers make adjustments before mass production, saving time and cutting costs.

Regulatory Compliance

Compliance with industry standards is non-negotiable. Early identification of relevant regulations ensures that the product design meets the required safety, performance, and environmental standards.

It’s recommended to stay updated on regulations to prevent potential legal challenges or costly rework down the line.

Clear Timelines and Milestones

Clear timelines and milestones are key to keeping development on track. Regular check-ins help stay aligned with goals and tackle issues as they come up. A structured approach helps prevent delays and keeps the process moving smoothly.

Why choose Sedin Engineering for New Product Development?

Developing a new product requires careful planning, collaboration, and attention to detail.

At Sedin Engineering, we simplify the new product development process with a design-first approach. Our team conducts in-depth market research, cost estimation, and material availability analysis to ensure your concept is feasible and production-ready within your timeline and budget.

With expert engineering and product design services, we deliver efficient, cost-effective solutions that meet regulatory standards and your operational needs.

Why outsource to us?

- Do it Right the First Time: Our engineers focus on providing optimal designs, reducing iterations, and staying within your budget.

- Customized Solutions: We work closely with you to create unique designs tailored to your specific requirements.

- Innovation-Driven: We use the latest tools and technologies to bring fresh ideas to life.

- Rigorous Quality Control: We ensure your product meets all specifications and regulations.

- Cost-Effective: Our industry knowledge helps deliver high-quality designs at the best possible price.

- Quick Turnaround: We work fast, getting your product to market sooner, giving you a competitive edge.

Let us handle the design, so you can focus on growing your business and launching products faster.

We design products for industries like automotive, material handling, medical, agriculture, renewable energy, and more. Contact us today to get started!