Mechanical Design

Controls Engineering

Robotic Simulation

Industrial Automation Services

We partner with OEMs and clients to optimise production line efficiency, from concept to finished design, ensuring seamless technical and business performance.

What's on your design request?

OUR CLIENTELE

Trusted clients

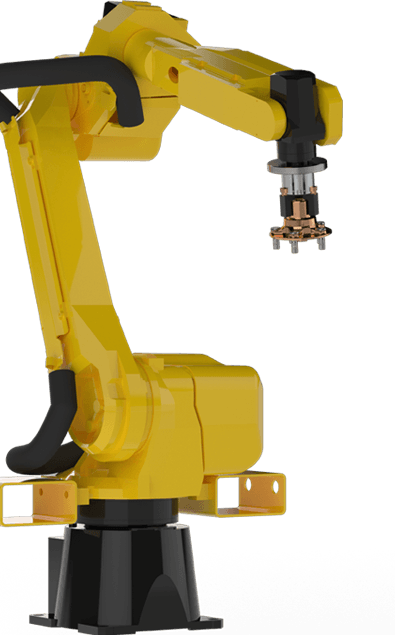

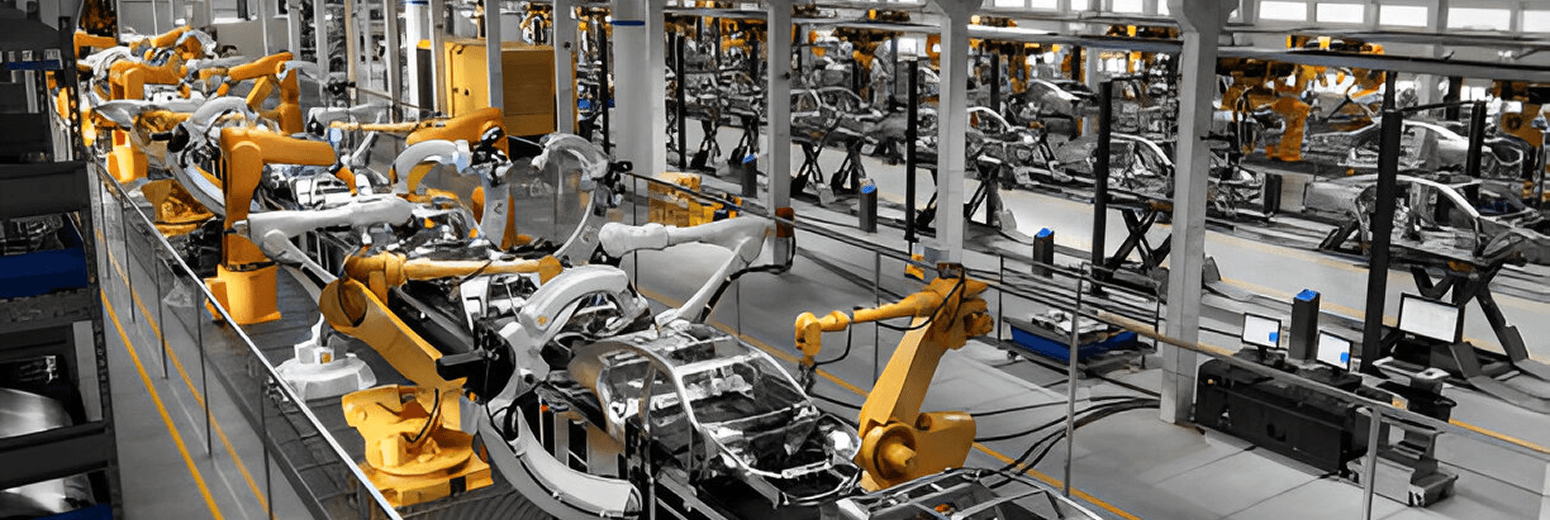

Mechanical Design

Mechanical design is crucial in industrial automation, ensuring efficient and reliable systems. We conceptualise, develop, and optimise mechanical components and systems for automation, from intricate machinery to crafting robust mechanisms. Our services span general and specialised automation fields like Automotive Assembly Lines, Material handling, Welding, Testing, Conveyor systems, Robotic arms (EOAT), Tool design and Special Purpose Machines.

Our designs ensure DFM techniques, impeccable welds, reduced human error, Improved performance and enhanced safety in the manufacturing process.

Adhering to the motto of “Do it Right the First time” , we follow the simple process below for the Mechanical Design: Concept >> Finished Design >> 2D Drafting

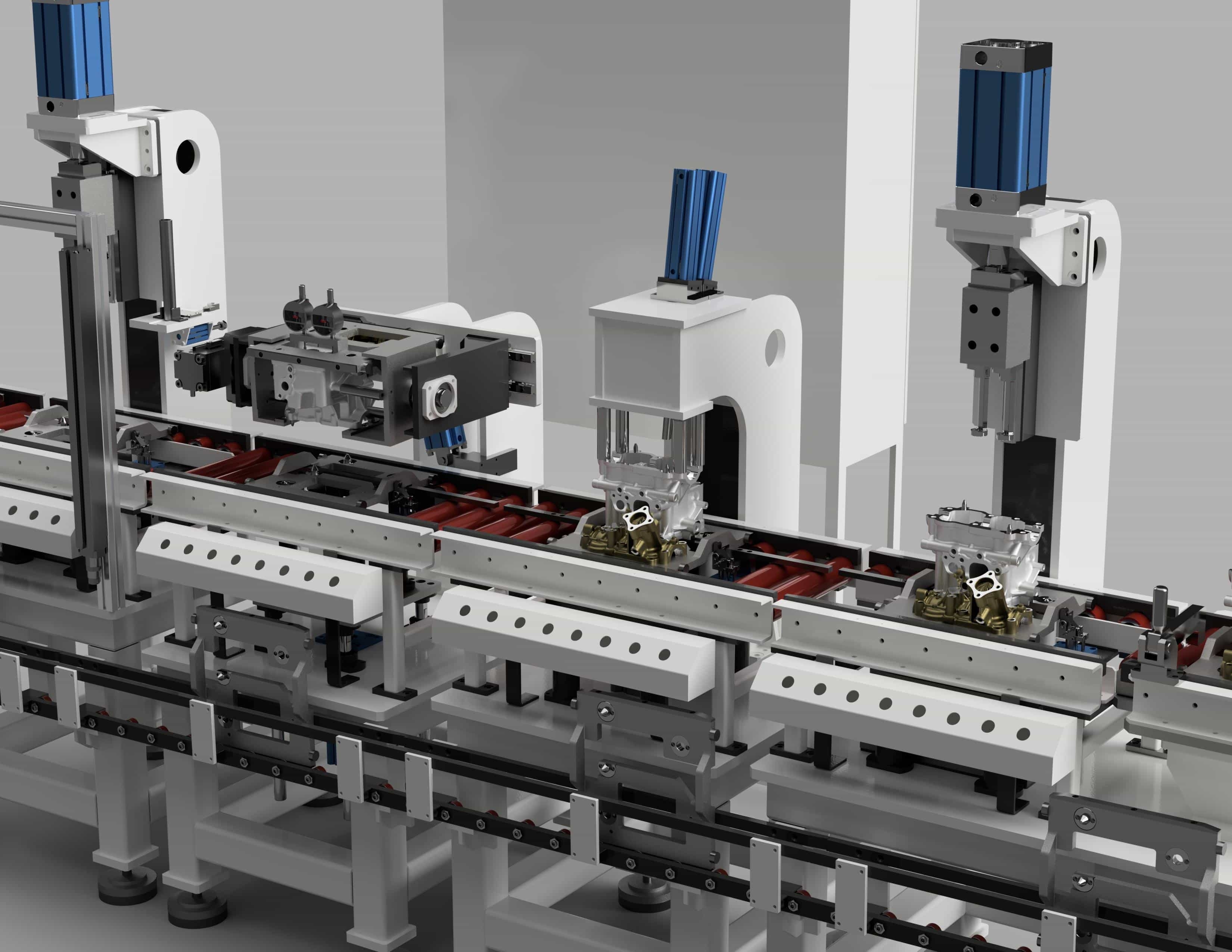

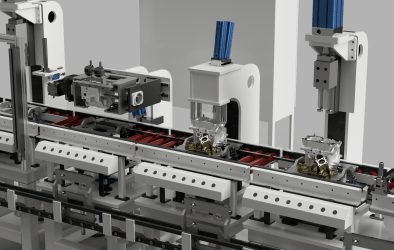

Cylinder Head Assembly Line

Boosted production efficiency by streamlining the cylinder head assembly process for a leading Indian 2-wheeler manufacturer.

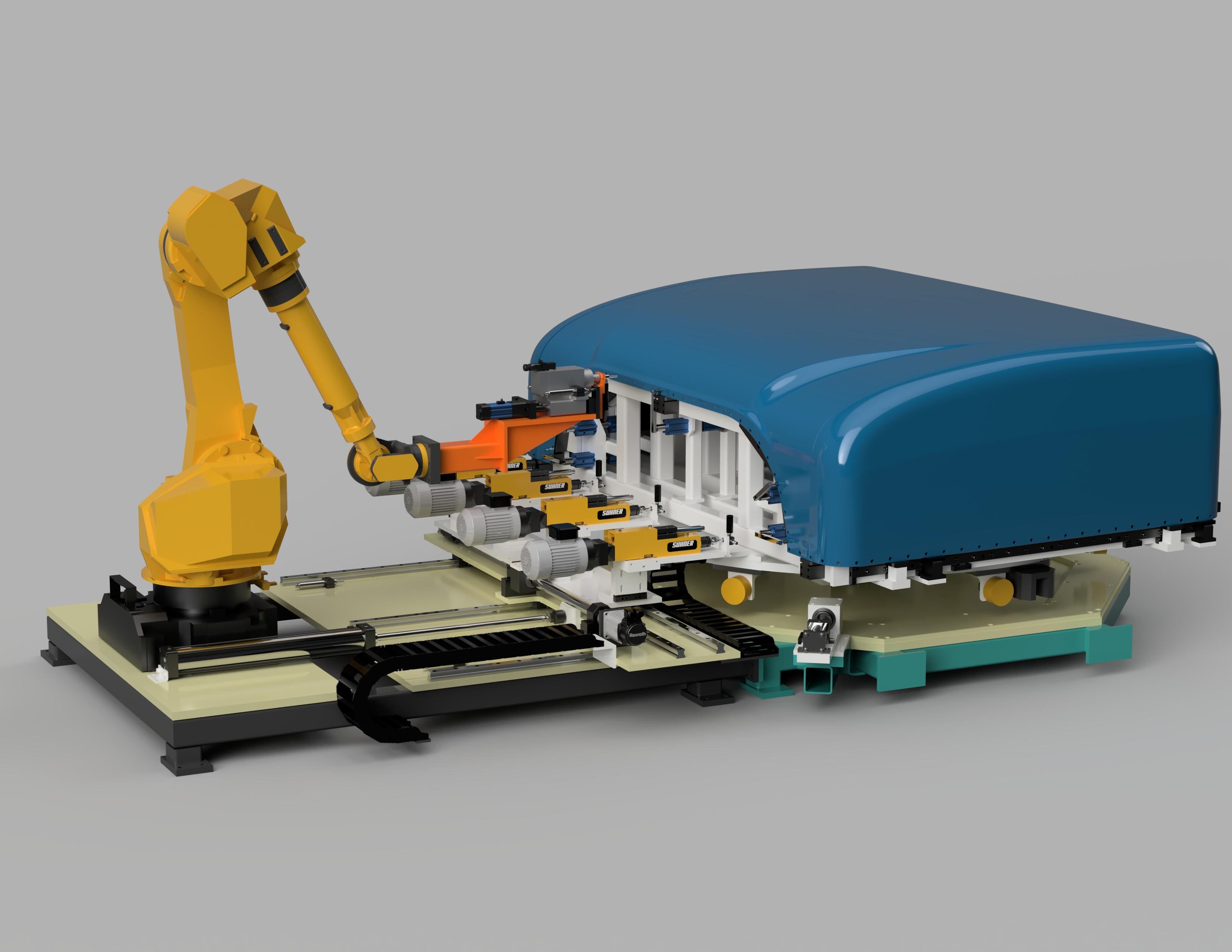

Robotic Drill Cell

Optimized drilling operations for sleeper roof caps with an innovative robotic cell, cutting lead times and ensuring precise, efficient production.

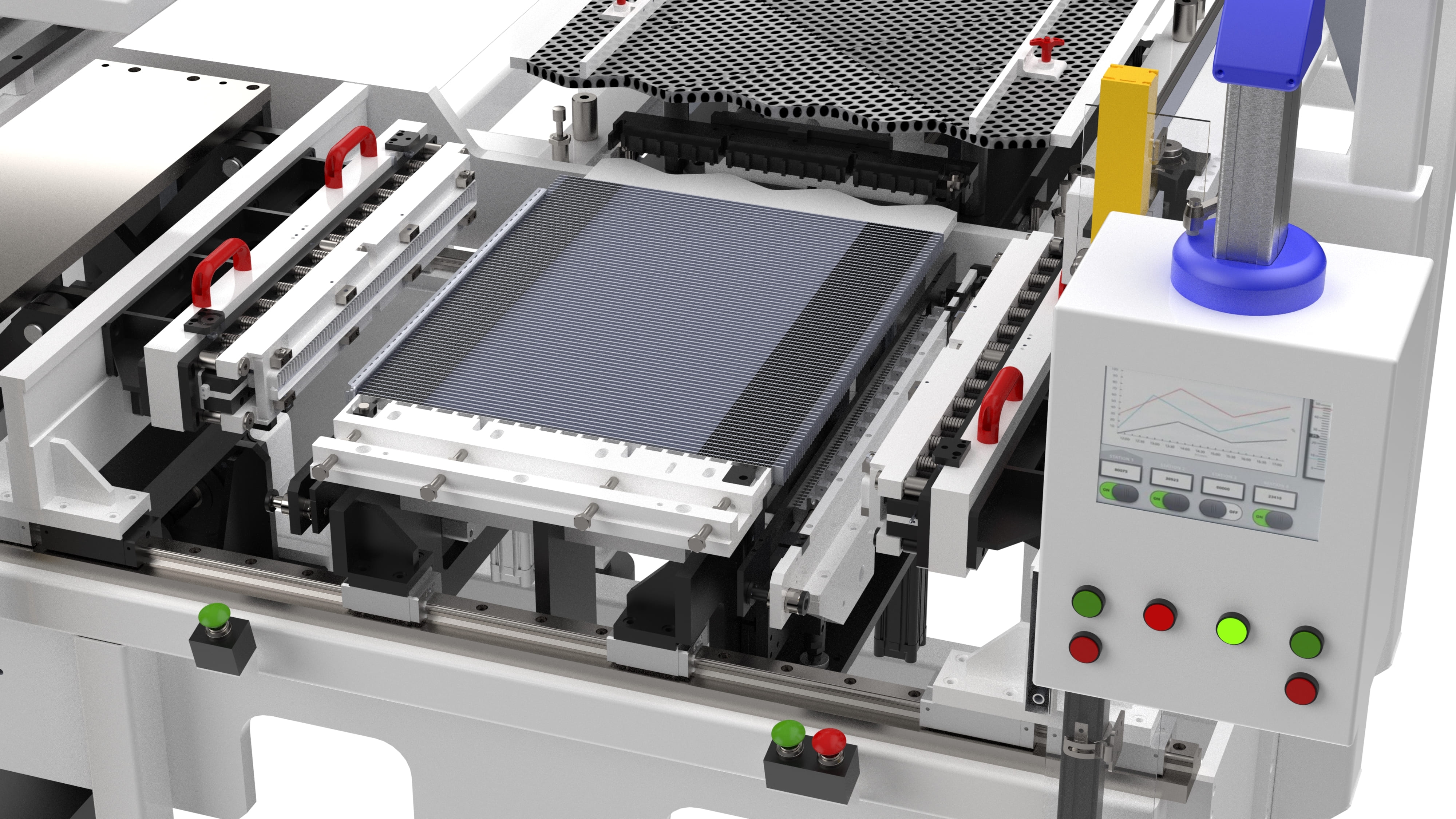

Radiator Assembly

Enhanced production with a semi-automated assembly machine, reducing cycle time and accommodating five radiator variants seamlessly.

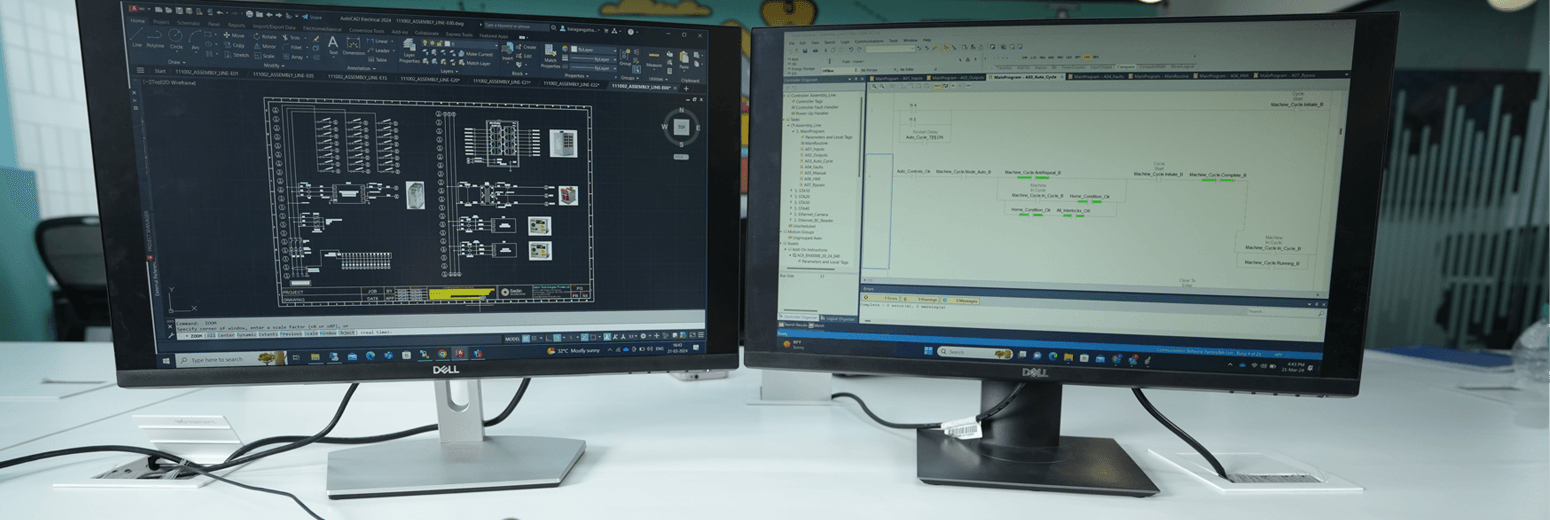

Controls Engineering

Controls engineering is essential in automation, designing systems to control machines and processes by combining electrical, mechanical, and systems engineering with sensors and actuators using PLCs, SCADA, and SERVO programming. Our engineers create algorithms to integrate hardware and software through feedback and feedforward strategies.

They develop high-quality HMIs for operator interaction and use simulation tools to optimise performance. With extensive experience, we automate applications for efficient, safe, and reliable machine operation, enhancing productivity, ensuring safety compliance, supporting maintenance, troubleshooting complex processes, and achieving precise results.

Our controls team is versed in variety of hardware, software and networking devices as well as integration with higher level data collection systems that are safe, reliable and user friendly.

Designing PLC & HMI Programs for Cylinder Head Assembly

Learn how our efficient PLC and HMI programming for cylinder head assembly helped an automotive supplier improve efficiency, productivity and safety.

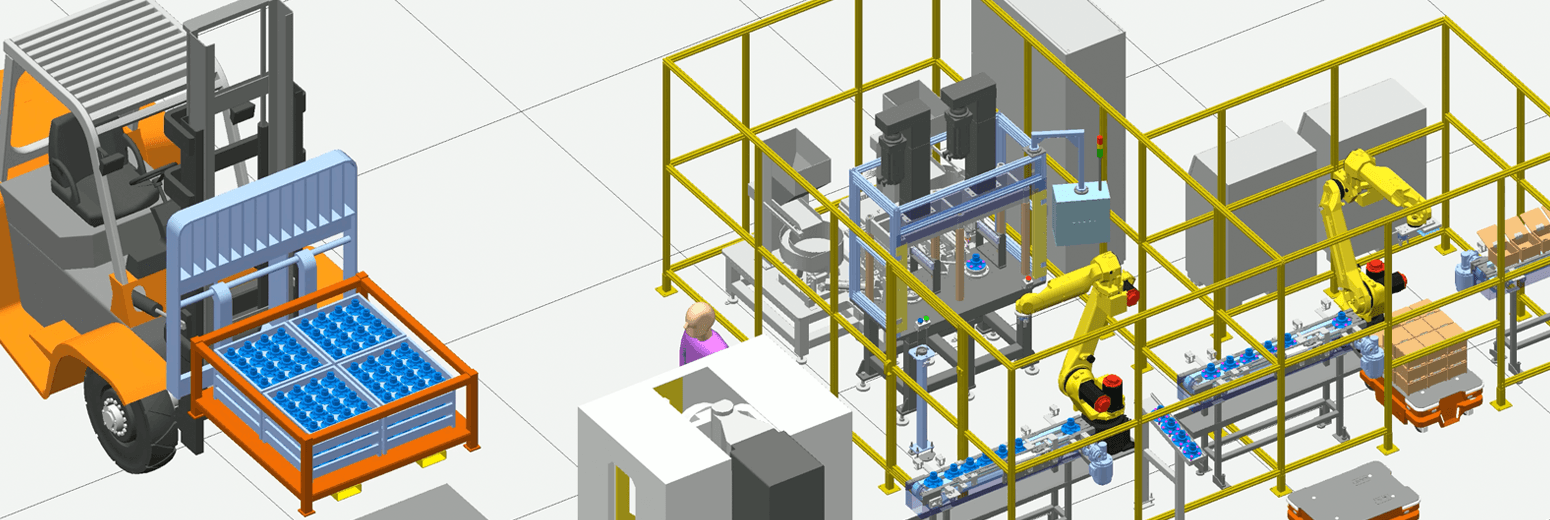

Robotic Simulation

Our Robotic Simulation service provides virtual validation and optimization of robotic systems before real-world deployment. We handle design validation, robot reach analysis, motion analysis, ergonomics, peripheral selection and verification in collaborative environments. We ensure collision-free path planning and provide high-fidelity offline programming (OLP) to reduce cycle time, ensure efficiency, and enable seamless integration with real robots.

We simulate different scenarios and evaluate human-robot interactions to identify issues, improve designs, and ensure seamless & safe integration of robots into human-centric workflows, ultimately reducing costs, improved accuracy, and productivity in the virtual environment.

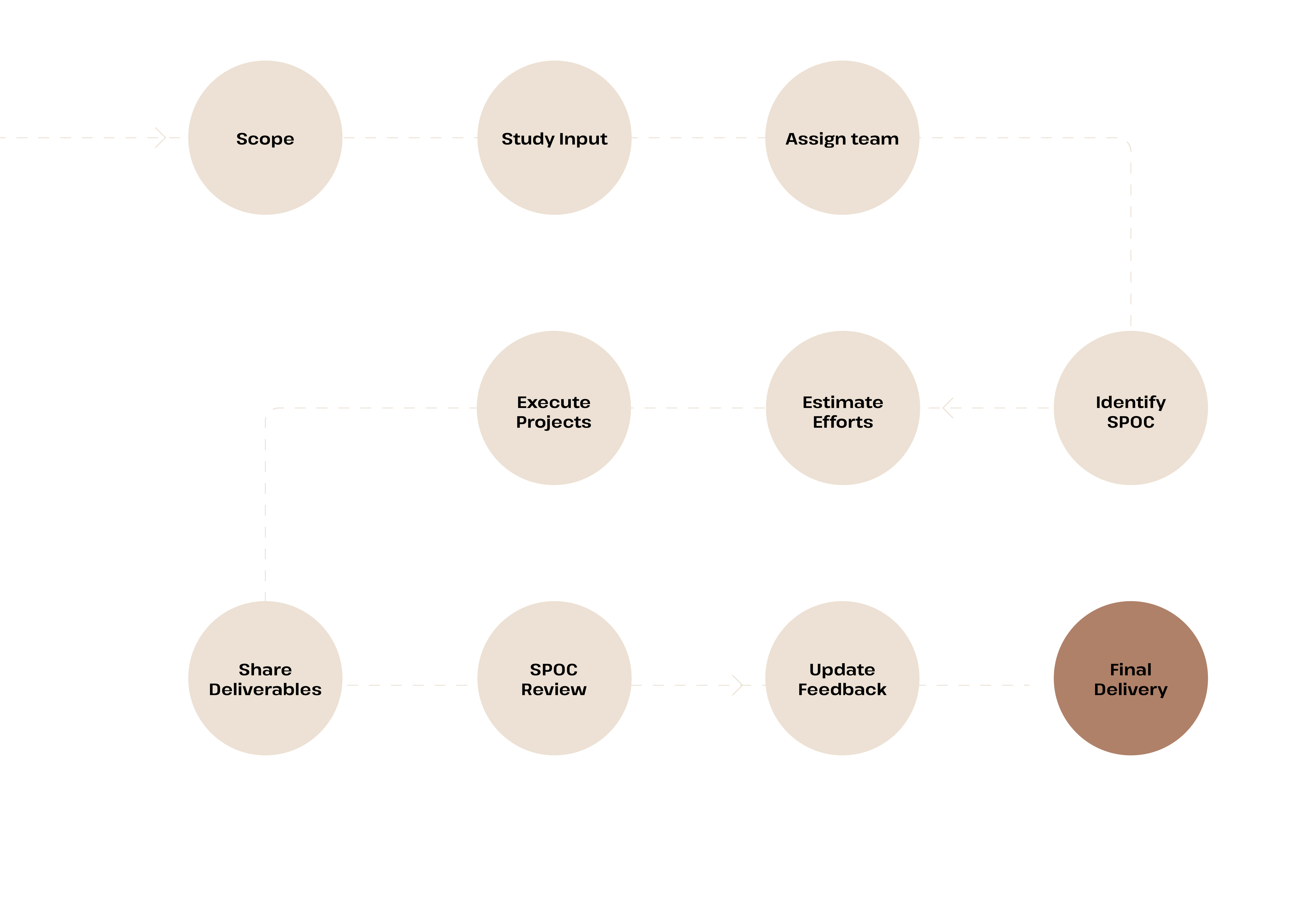

Our 10-step approach to excellence

Our clients often say it best: our 10-step process is rigorous, foolproof, and methodical. It's not just a mantra; it's how we do things here at Sedin Engineering.

Technologies we use

AUTOCAD

SOLIDWORKS

AUTOCAD ELECTRICAL

ROBCAD

PTC CREO

INVENTOR

E-PLAN

FANUC ROBOGUIDE

AUTODESK VAULT

SOLIDWORKS PDM

ALLEN BRADLEY

DASSAULT DELMIA

VENTION

3D EXPERIENCE

FACTORY TALK

SIEMENS TECHNOMATIX

MITSUBISHI ELECTRIC

SCHNEIDER ELECTRIC

SIEMENS AUTOMATION

ABB ROBOSTUDIO

CODE SYS

B&R

GE DIGITAL

CIM STATION ROBOTICS

KAWASAKI

MOTOMAN

OMRON

KUKA SIM

Industries we serve

AUTOMOTIVE

INDUSTRIAL AUTOMATION

PACKAGING

FOOD & BEVERAGE

METAL FABRICATION

AGRICULTURE

MATERIAL HANDLING

DAIRY PRODUCT MANUFACTURING

MANUFACTURING

HEAVY MACHINERY

MEDICAL

ENTERTAINMENT

Industrial Standards

ANSI/ASME

AS/NZS

ISO

ISO 2768

BS EN 1993

AS 1170

API

VOICES OF DELIGHT

Stories shared by our happy clients

Relevant Services

Automotive Assembly line

- Cylinder Head Assembly line

- Engine Assembly

- Radiator Core assembly

- Cylinder Block Assembly

- Robotic Drill Cells

- Robotic Dispensing Cell

- Dispensing and Bonding

- Robotic Clips

- Robotic Screw

- Glass Bonding

Material Handling Applications

- Conveyors

- Bottle Capping Assembly

- End Of Arm Tool (EOAT)

- Pick & Place Assembly

- Case Erector Machine

- Pallet

- Linear Transport Equipment

- Automated Guided Vehicle

Special Purpose Machines (SPM)

- Hydraulic Pressing Machines

- Drilling & Routing Machines

- Clip Insertion Machines

- Jig & Fixtures

- Servo Pressing Machines

- Tightening System

- Punch Press Machines

- U-Cap Servo Machines

- Greasing & Pressing Assembly

Testing & Vision System

- Vision System Cell

- Leak Testing Machine

- Torque to Turn Checking Machine

- Float checking Machine

- Vision System Standalone

Welding Application

- Rear Axle Arc Welding Fixture

- BIW Welding fixture

- MIG Welding Cell

- TIG Welding Cell

- Sonic Welding Machine

- Ultrasonic Welding Cell

- Robotic Welding Cell

Semi Conductor

- QCM Module

- Vacuum Chamber and Frame

- Design

- Gas Box Assembly

- Equipment Front End Module

- Load Lock Chamber

- TM Chamber

- Vacuum Robot