Do your engineers spend hours doing the same CAD tasks over and over? What if you could save or completely eliminate those hours? That’s exactly what CAD automation does. It takes over the repetitive design work, helping your team move faster, reduce errors and take on more projects without extra effort.

In this blog, we’ll break down what CAD automation is, how it improves design workflows and some real-world use cases where CAD automation saves you the most time.

What Is CAD Automation in Manufacturing?

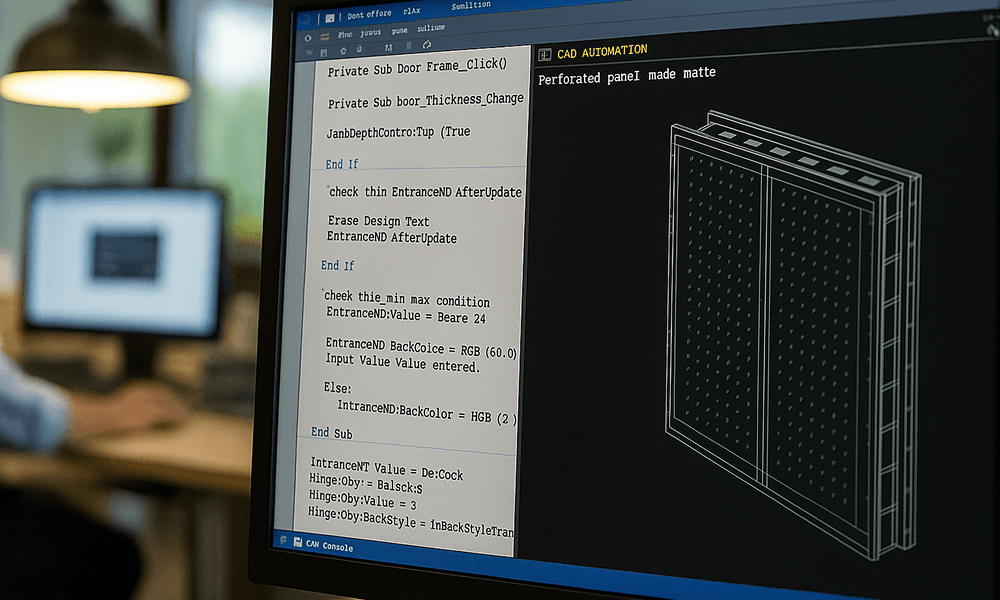

CAD automation in manufacturing refers to the use of custom scripts, macros, or rule-based systems to speed up and simplify repetitive design tasks in CAD software.

Instead of manually creating each model or drawing, automation allows design engineers to generate entire parts, assemblies and documentation with just a few inputs like dimensions, materials or configuration options.

It’s especially benefits companies that deal with configurable products or repeat similar designs.

Why Use CAD Automation in Manufacturing Design?

Manufacturing design involves many repetitive, time-consuming tasks like, modifying part dimensions, creating drawings, updating BOMs (Bill of Materials) and so on. These tasks consume valuable engineering time and increase the risk of errors.

CAD design automation solves this by turning such manual steps into repeatable, rule-driven processes. You can generate models, assemblies and drawings automatically with just a few inputs. The result? Faster design cycles, fewer mistakes and more time for your engineers to focus on innovation instead of repetitive CAD modeling.

If you're dealing with high product variation, tight deadlines or increasing demand, CAD automation helps you scale design work without scaling your team.

How Does CAD Automation Work?

CAD automation speeds up the design process by using technology to handle repetitive tasks. It’s especially useful in new product development, where quick changes and early accuracy are required. Here’s how it works:

1. Define the inputs

You start by entering values like dimensions, material type, number of holes or layout choices — anything that normally changes from one design to another.

Example: For a custom enclosure, you might enter its height, width, and number of openings.

2. Apply design rules

The system uses built-in logic (set of predefined rules) to adjust the model based on your inputs, controlling features, dimensions and configurations automatically.

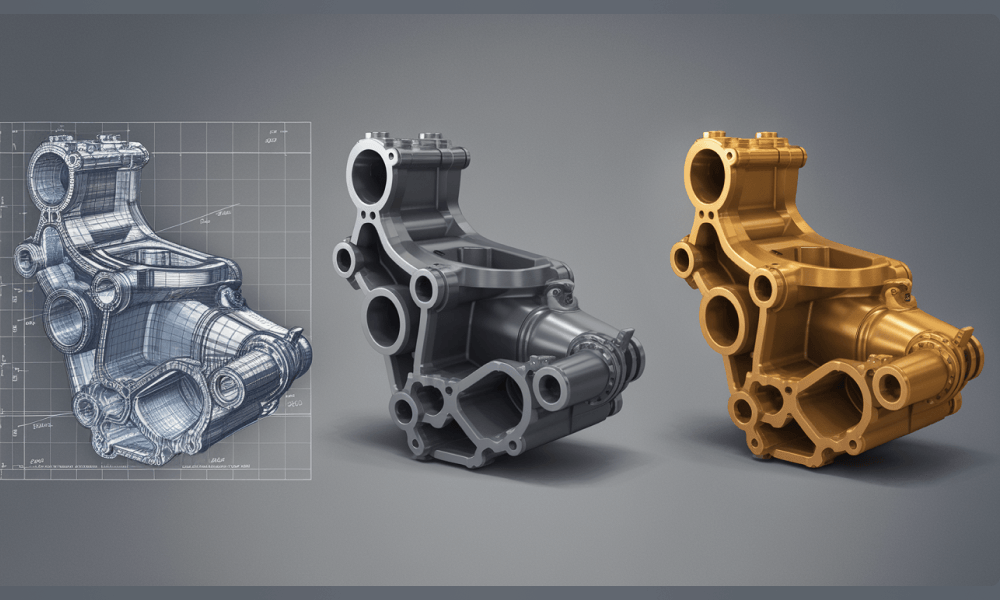

3. Models and drawings are auto-generated

Once the logic runs, CAD automation generates:

- 3D models

- Annotated 2D drawings

- BOMs (Bill of Materials)

- Export files like DXFs or PDFs

All of this happens without redrawing anything manually.

4. Outputs are ready for manufacturing

The system can also handle file naming, folder organization, and bulk exporting, so your outputs are manufacturing-ready.

Example: You can export 20 variations of a bracket—each with its own drawing and DXF, in just one click.

Real-World Use Cases of CAD Automation

Here are some practical scenarios where automated CAD workflows drastically reduce design time and effort:

Designing sheet metal enclosures in different sizes

If you design electrical boxes, control panels or server racks, you know how often sizes and cutouts change from one customer to the next. Instead of redrawing each variation, automated CAD tools let you enter key dimensions and instantly create the right model and drawings. No need to start from scratch every time.

Creating 2D drawings and BOMs for similar parts

Many industrial equipment manufacturers regularly produce components like brackets, flanges and other simple parts in high volumes. Manually creating drawings and BOMs for each of these components can be time-consuming. With CAD design automation, you can generate all the 2D drawings and parts lists at once — fully labeled and ready for production.

Modelling custom jigs and fixtures with built-in design rules

Jigs and fixtures are used to hold or guide parts during manufacturing. They often follow specific design rules, like fixed hole spacing, minimum clearances or standard material thickness. Using rule-based CAD automation, you can integrate these rules into your models. When something changes, for instance, the size of the baseplate, the rest updates automatically, without errors.

Handling engineering changes in large assemblies

If you're designing large assemblies like security doors, machine frames, robotic cells,, or food machinery equipment such as boilers, hoppers, etc., a small change can affect the entire assembly. With automated CAD workflows, you only need to update one value and the system adjusts all related parts, drawings and BOMs for you. What used to take hours now takes minutes.

Exporting DXF and PDF files for manufacturing

CAD teams often need to deliver detailed 3D models and technical drawings to the manufacturing shop on a regular basis. Handling each file manually can be time-consuming and error-prone. With CAD automation, engineers can batch-export DXFs and PDFs, complete with correct file names, layers and formats. All in just one click.

Key Benefits of CAD Automation in Design

We’ve already seen how CAD design automation helps eliminate repetitive tasks, speed up modeling and reduce manual work.

But having worked on several CAD automation projects, we can tell you there’s more to it than saving time. Here are some more benefits that go beyond speed and efficiency. These can make a real difference in how you design, scale and deliver.

1. Eliminate manual errors from the start

Manual CAD work often leads to small but costly errors—like incorrect dimensions, missing features, or wrong layer names. With automated CAD drawings and models, everything is generated based on predefined rules, ensuring accuracy from the very first output. That means fewer revisions and faster approvals.

2. Keep every output consistent

With automated CAD workflows, your parts, assemblies and drawings follow the same standards across teams, projects and product lines. Also, the file names, dimensions, layers and templates stay uniform. This makes it easier for manufacturing or fabrication teams to understand and use the data right away.

3. Create product variants without rebuilding models

Need 50 versions of a control panel or 20 sizes of a bracket? Instead of starting from scratch each time, automation lets you input values like width, height, hole patterns and instantly generate fully detailed models and drawings. This is where CAD design automation really proves its value.

4. Scale design output without growing your team

With automation in place, your design capacity grows without increasing your team size. Whether it’s 10 or 100 custom requests, the system generates models and outputs faster than a manual workflow ever could—without burning out your engineers.

5. Make file delivery to the shop floor easy and error-free

Automation creates everything the shop floor or vendors need like DXFs, PDFs and BOMs with the correct names and formats. No more last-minute fixes or confusion. This helps production start on time, with fewer errors or questions.

6. Capture design knowledge inside the system

One underrated benefit: design rules are built into the system, not in one engineer’s head. This makes it easier to onboard new team members, shift work between teams, or scale without losing design accuracy and quality. CAD automation future-proofs your design process.

Best CAD Software for Design Automation

Once you understand the benefits of CAD automation, the next step is choosing the right platform to implement it. The good news? You don’t need to buy new software. Many popular tools already support design automation through built-in features or add-ons.

Here’s a closer look at the most widely used CAD software for design automation and how each supports automated, scalable workflows.

SOLIDWORKS (DriveWorks or VBA)

SOLIDWORKS is one of the most widely used CAD platforms in manufacturing and it becomes much more powerful when paired with automation tools like DriveWorks or VBA.

What is DriveWorks?

DriveWorks is a design automation and CPQ (Configure-Price-Quote) tool built specifically for SOLIDWORKS. It allows you to create input forms where users can enter product specs (like width, height or hole patterns), and DriveWorks automatically generates the 3D model, 2D drawings and BOM—without human intervention.

What is VBA in SOLIDWORKS?

VBA (Visual Basic for Applications) lets you write simple scripts (called macros) to automate repetitive tasks like exporting DXFs, placing standard views or renaming files. It’s great for teams that want quick automation without investing in complex systems.

Autodesk Inventor (iLogic Programming)

Autodesk Inventor supports automation using a feature called iLogic, a rule-based design tool that’s integrated directly into the modeling environment.

What is iLogic?

iLogic is a built-in functionality in Inventor that lets you create logic-based rules through a simple, user-friendly interface. These rules can control features (like suppressing holes), adjust dimensions, change materials or even generate drawings based on parameters. You can create smart, reusable models that adapt based on user inputs or design intent.

AutoCAD (VBA)

AutoCAD may be 2D-focused, but it’s still widely used in manufacturing for layout drawings, schematics and fabrication-ready documentation.

What is VBA in AutoCAD?

Just like in SOLIDWORKS, VBA is integrated into AutoCAD and allows you to create and run macros to automate repetitive tasks like updating block attributes, cleaning up layers, standardizing title blocks or batch-processing DWG files. It’s an easy way to speed up 2D drafting tasks without needing extra software or switching tools.

PTC Creo (Pro/PROGRAM and Mapkeys)

PTC Creo is a powerful 3D CAD platform widely used in automotive, aerospace and industrial equipment manufacturing. It supports design automation through Pro/PROGRAM, Mapkeys and advanced APIs.

- Pro/PROGRAM lets you control your model with built-in rules. It can suppress features, change sizes, or adjust geometry based on parameter inputs.

- Mapkeys are shortcuts that automate repetitive actions like creating features or views.

- For advanced automation, Creo Toolkit (C++) allows full customization and integration with PLM or ERP systems.

Advanced Automation Using C# and CAD APIs

For teams that need more flexibility or want to build custom tools, C# programming is a powerful way to automate tasks across multiple CAD platforms.

- In SOLIDWORKS, Inventor, and even Revit, you can use C# to access the API and automate everything from feature creation to drawing exports.

- C# is especially useful when you need to integrate CAD with other systems (like ERP or quoting tools) or batch-process large amounts of data.

- It’s best suited for companies with in-house developers or engineering partners who can build and maintain automation tools tailored to your workflow.

Is CAD Automation Right for Your Business?

CAD automation works best when you're designing repeatable products or handling high design volume.

It’s a great fit if:

- You design similar products with different sizes or layouts (e.g. brackets, frames, enclosures)

- Your team spends too much time on drawings, BOMs, or file exports

- Frequent design changes slow you down across models and drawings

- You’re trying to keep up with growing demand without expanding your team

- You want more consistent file outputs, naming, and documentation

But you may not need it if:

- You work on fully custom, one-off projects with little reuse

- You have low design volume and no urgency to scale

- Your products aren’t parameter-driven or reusable

If your team is constantly “editing old files to save time,” you’re already doing manual automation the hard way. A proper system just makes it reliable and scalable.

Get Started: CAD Automation Services That Fit Your Workflow

Sedin Engineering offers customized CAD automation services for manufacturers looking to speed up repetitive design tasks, reduce errors, and save engineering time.

Whether you're designing product variants, generating complex drawings or scaling up your output, automation makes the process faster and more consistent.

Want to see how it can work for your team?

Explore our Product Design Services to learn how we can help you implement CAD design automation that’s tailored to your needs.