Steel detailing may look like a small step in your structural engineering project. But it has the power to make or break the entire process.

A single mistake in the details can lead to delays, rework, and extra costs. In the fast-paced world of engineering and construction, these issues can quickly spiral out of control and affect your budget and timeline.

In this blog, we’ll explain why you can’t ignore structural steel detailing. And how getting it right from the start saves you time and money and keeps you compliant. Let’s dig in!

What is structural steel detailing?

Steel detailing is the critical link between engineering design and fabrication. It involves creating detailed drawings and documentation that guide fabricators and erectors in assembling steel structures correctly.

A steel detailer is responsible for making sure that every beam, column, brace, and connection is accurately represented so manufacturers and builders can avoid costly errors.

Think of it like an instruction manual for steel structures. Without it, fabrication and installation become a guessing game, which leads to wasted materials, delays, and safety risks.

Key components of structural steel detailing

A comprehensive structural steel detailing includes:

a. Shop drawings

These are your step-by-step guides for fabricating steel parts. They show:

⁃ Exact dimensions for cutting and drilling steel parts ⁃ Number of bolts, bolt hole sizes and locations ⁃ Welding instructions for assembling different sections ⁃ Material specifications (what type of steel/aluminum to use)

b. Erection drawings

These help construction crews install everything in the right place. They include:

⁃ Erection sequence ⁃ Where each beam, column, and connection go ⁃ How different parts fit together ⁃ Which connections are bolted vs. welded

c. Bill of Materials (BOM)

A detailed list of all the materials needed for the job, including:

⁃ Steel beams, plates, supports and braces ⁃ Bolt sizes and quantities ⁃ Welding materials

d. Connection details

These drawings explain:

⁃ How steel pieces attach to each other ⁃ The type and size of welds ⁃ What bolts and fasteners to use and how tight they need to be

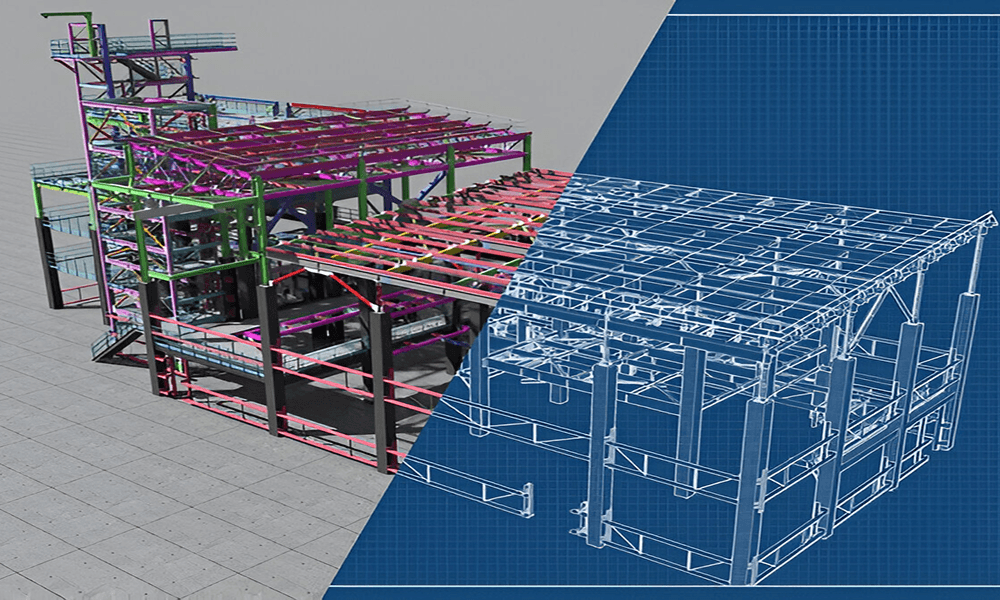

e. 3D models & clash detection

Many steel detailers now use CAD modelling software like Tekla, Advance Steel, Revit, or AutoCAD to catch design issues before fabrication starts, preventing costly mistakes.

f. Assembly instructions

Sometimes, detailing includes guidelines on:

⁃ The order to install steel parts ⁃ Which sections should be welded in the shop vs. on-site ⁃ Lifting points for cranes to safely move large pieces

Looking for the best structural steel detailing services? Let's talk.

The cost of poor steel detailing

So, now that we know what steel detailing is, let’s talk about why detailing alone isn’t enough. It has to be done right. Poor detailing can cause more harm than no detailing at all.

A small mistake can trigger a chain reaction—delays, wasted materials, and rising costs. What seems like a small error on paper can turn into a major headache on-site.

Here’s why:

1. Fabrication errors mean wasted steel & labour

Let’s say a beam arrives at the shop, only to discover the bolt holes are in the wrong place. Now what?

☐ Best-case scenario: The fabricator spends extra hours fixing the mistake. ☐ Worst-case scenario: The steel is scrapped, and a new order is placed, delaying the entire project.

Either way, poor detailing means more time, more materials, and more money down the drain.

2. Construction delays drain time & money

On a construction site, every piece of steel needs to fit perfectly. If columns, beams, or braces don’t align because of a detailing error, the entire project comes to a standstill. And delays aren’t cheap:

☐ Idle crews waiting for corrections = Lost labour costs ☐ Rushed last-minute field modifications = Extra expenses ☐ Project delays = Penalties, lost bonuses, and frustrated clients

Steel detailing mistakes don’t just slow things down. They create a domino effect that throws entire schedules off track.

3. Safety risks & compliance issues

Steel structures must follow strict safety codes like AISC, AWS, OSHA and regional industry standards. A detailing error can cause weak connections, load issues, or instability. That means failed inspections and costly emergency fixes. And worst, a structural failure that risks lives.

At Sedin Engineering, we strictly follow structural steel design principles to ensure every detail meets safety codes and local regulations. Our structural steel drawings and models provide clear and accurate guidance for manufacturers, fabricators, and erectors to get the job done right.

4. Rework (the silent profit killer)

One of the biggest hidden costs in steel fabrication? Rework.

Every time an engineer has to revise drawings, or a fabricator has to fix an error, the costs pile up leading to additional engineering fees and extra material handling.

Rework eats into profit margins fast. Investing in precise steel detailing upfront is always the cheaper option.

5. A reputation that’s hard to fix

In the steel industry, reputation is everything. One bad project can mean:

☐ Lost trust from clients and contractors ☐ Fewer referrals ☐ Negative impact on your company’s credibility

Benefits of accurate steel detailing

The best way to avoid these costly mistakes is accuracy. When steel detailing is done with precision and attention to detail, it eliminates fabrication errors, prevents costly rework, and keeps projects on track.

Here’s why getting it right the first time makes all the difference.

- Prevents costly mistakes: One wrong connection can mean delays and expensive rework. When the structural detailing is accurate, it ensures every piece fits the first time — no surprises, no do-overs.

- Speeds up production & assembly: With detailed shop drawings and precise BOMs (Bill of Materials), manufacturers cut production time, and fabricators assemble faster with fewer adjustments. That keeps projects on time and within budget.

- Ensures safety & compliance: Every steel structure must meet several local and international standards. Precision detailing ensures every bolt, weld, and beam meets these standards which reduces liability and prevents inspection failures.

- Reduces waste & cuts costs: Accurate steel detailing reduces waste, minimizes errors, and maximizes material use. This saves money and makes construction more sustainable.

- Keeps projects moving smoothly: Clear and precise structural detailing eliminates miscommunication between engineers, fabricators, and contractors. That means fewer RFIs, faster approvals, and no last-minute surprises that slow projects down.

ALSO READ: Introduction to Design for Manufacturing (DFM)

Expert steel detailing services that get it right the first time

At Sedin Engineering, we know that every detail matters. That’s why we deliver precision-driven structural steel detailing services that keeps your project on track.

With a deep understanding of industry-specific standards and expertise in the latest tools like Tekla Structures, Autodesk Revit and Advance Steel, our structural steel detailers deliver:

☐ Detailed shop and erection drawings for error-free fabrication and assembly ☐ Clear & accurate BOMs to streamline procurement and reduce material waste ☐ Code-compliant steel designs that meet safety standards

With our motto of do it right the first time, we make sure every detail is spot-on right from the start. Contact us today for high-quality structural steel drawings that keep your engineering project on track.