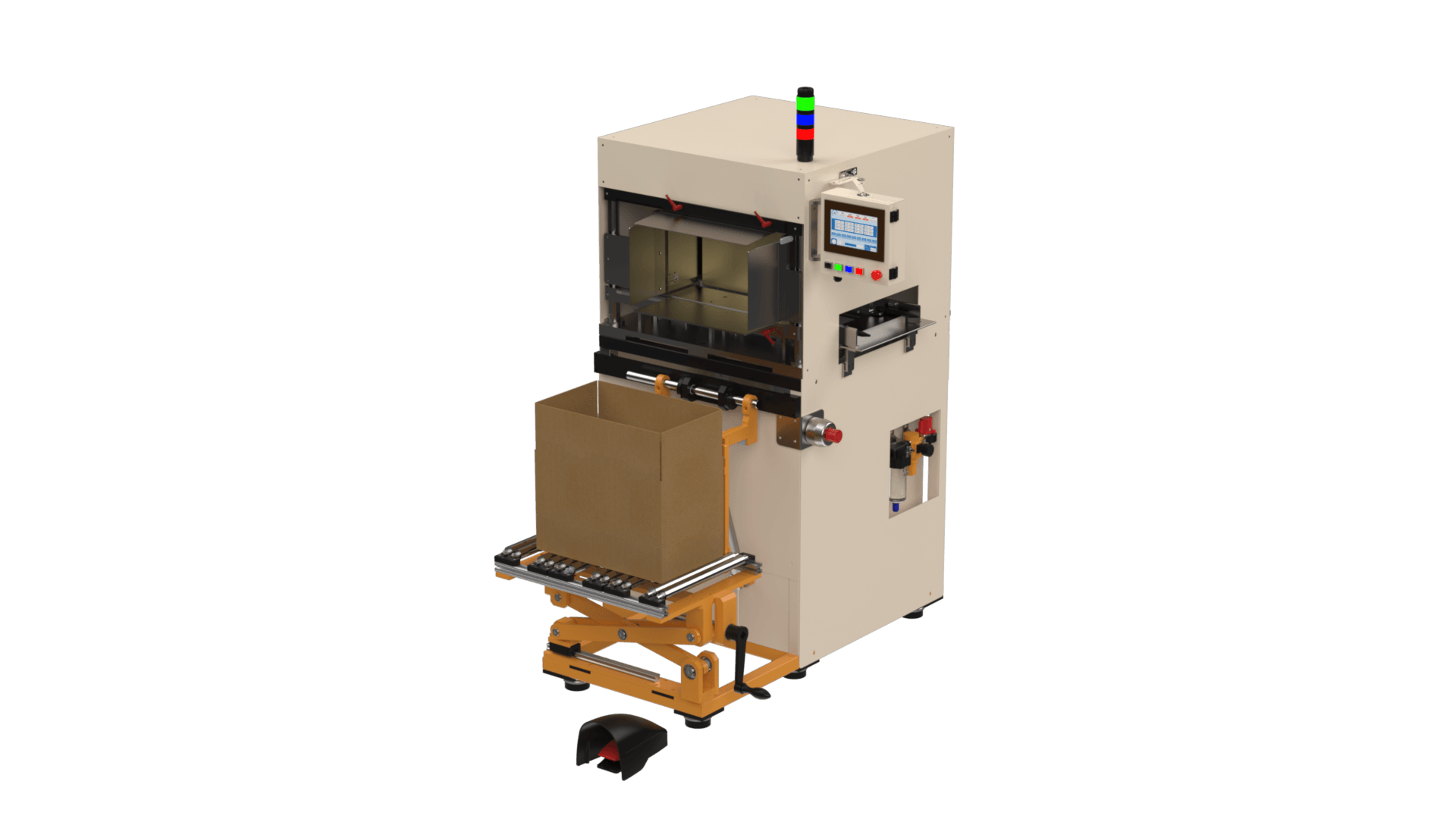

Based on the project scope, the filling station is designed to fill 4 bottles sequentially. As bottles approach the conveyor, 2 pneumatic cylinders are used to separate and position the bottles for filling. optical sensors detect the liquid level in the bottles to prevent overfilling or underfilling. The station also includes a vertical cylinder and flow sensors to ensure consistent filling.

After filling, each bottle is capped and positioned at the capping station using a servo indexer. Inductive sensors ensure precise alignment of the bottles and caps. Capping is managed by a vertical slide cylinder and a rotary gripper, aided by a cap sensor for positioning and a torque measurement sensor to ensure the caps are tightened to the correct specification. Nylon fingers securely hold the cap during the tightening process.

After capping, the bottles are labeled by the labelling unit and then transferred to the bottle transfer conveyor.

Through-beam sensors are used for counting bottles. Once the designated number of bottles is transferred and stacked, the Fanuc M10iA robot picks up 4 bottles at a time and places them into cartons of specified sizes. The robot is equipped with a state-of-the-art End Of Arm Tool (EOAT) designed by our team for precise bottle handling.

We used safety door switches to protect and detect any intrusion into hazardous areas and installed emergency stop buttons to shut down the system in case of an emergency.

Advanced sensors were utilised to optimise the filling and capping process, ensuring product quality, reducing waste, and enhancing safety, all while complying with the customer’s safety standards.