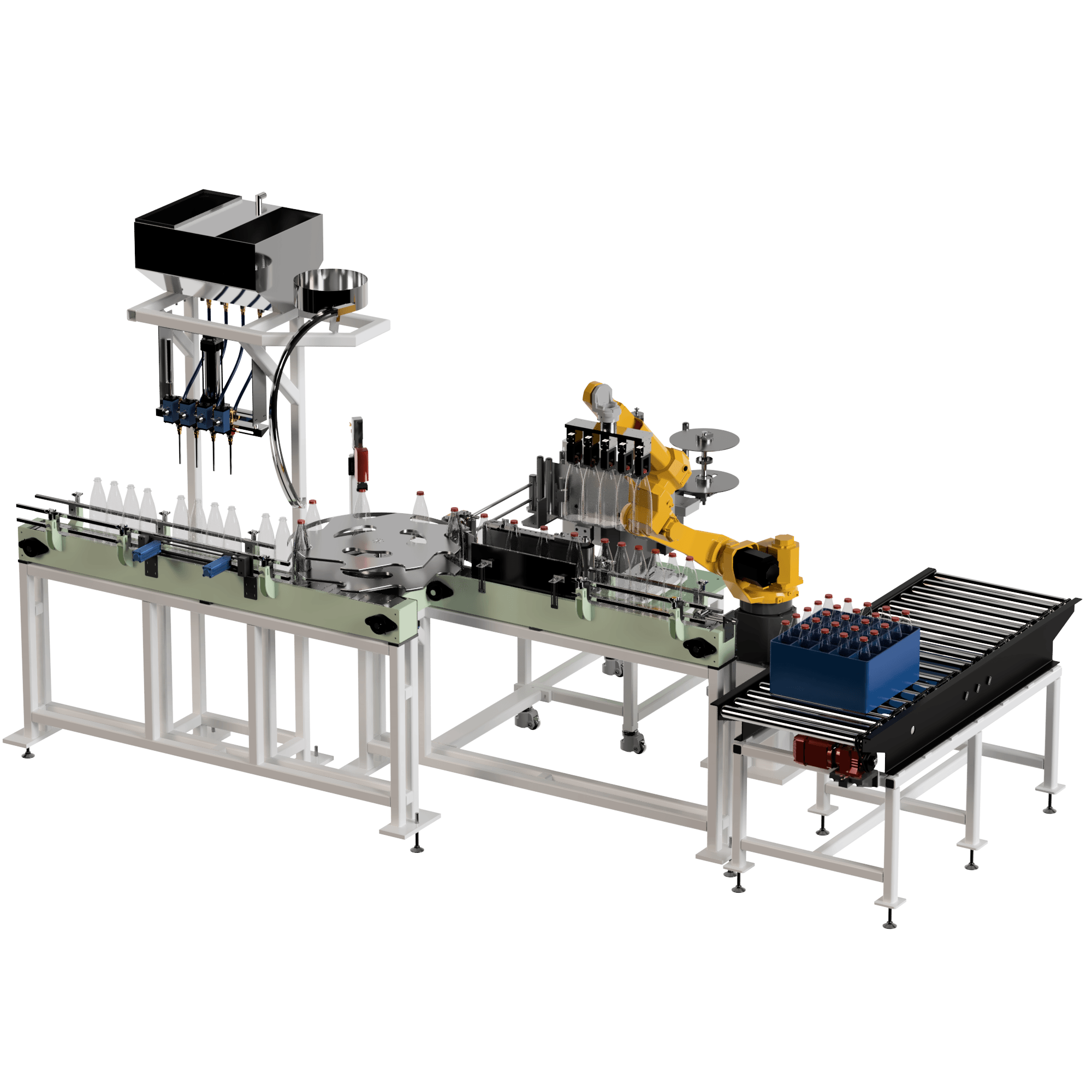

To achieve the project scope and overcome the challenges, a semi automatic Case packer machine was designed with the following solutions

Integration and Collection: Designed a semi-automatic case machine to integrate with the existing production line, to collect the product boxes and feeding them into the new system.

Automated Collation: The machine automatically collates boxes into the correct packing pattern using a pneumatic cylinder and pawl mechanism after they are gathered from the feed system.

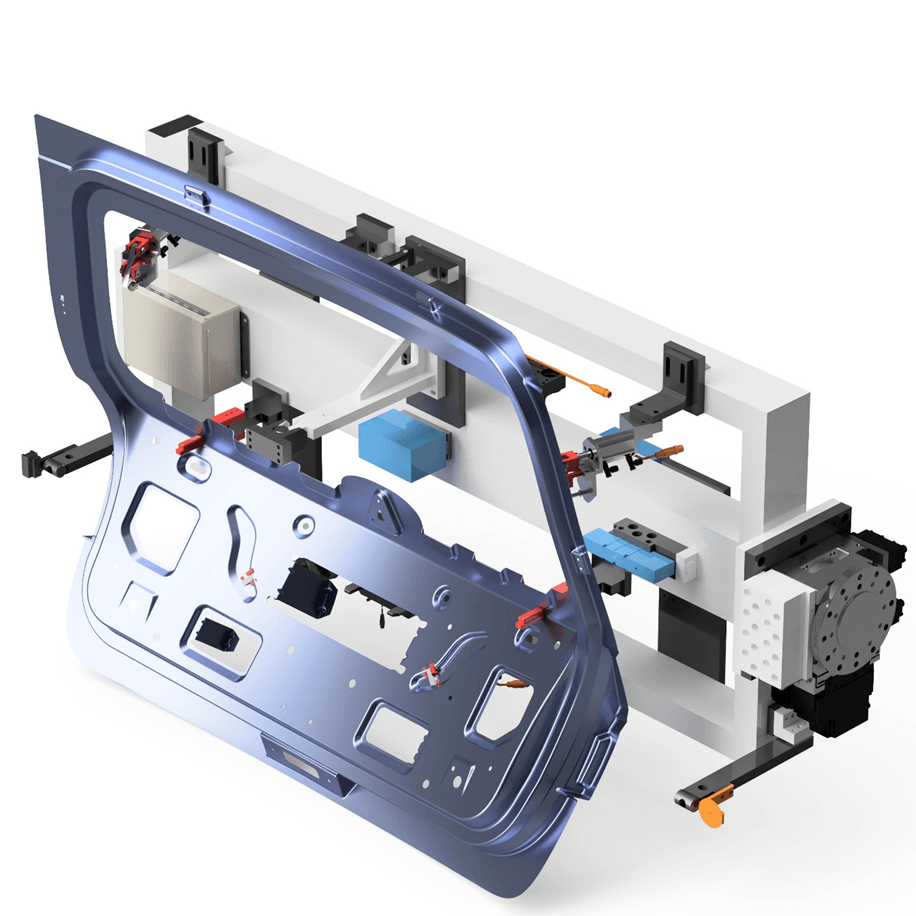

Adjustable Loading Station: A horizontal loading station was developed to handle various carton case sizes, featuring a scissor mechanism for height adjustment. The operator sets the height for each carton case size before starting the packaging process.

Box Loading Process: The operator places a carton case onto the horizontal loading station, positioning the open end over the loading funnel.

Carton Case Positioning: Pressing the foot pedal activates a pneumatic cylinder and linkage mechanism, tilting the loading unit to 90 degrees and aligning the carton case with the entry chute.

Automatic Filling: Product boxes are automatically filled into the aligned carton case through the entry chute.

Case Handling: The filled carton is pneumatically lowered and transferred via a roller conveyor to the next case taper station.

Versatile Design: The machine accommodates variable sizes and features a tool-free changeover setup.