We designed a semi-automated drill and router machine specifically for the EV battery front panel. The objective was to meet tight production targets while ensuring flexibility and accuracy.

This project brought together our core strengths in mechanical design and industrial automation services. The solution we delivered included the following key steps:

1. Precision Fixture for Complex Geometry

We developed a custom fixture that securely holds the front cover of the battery case without deforming it. The design accounted for the cover’s uneven thickness and complex shape. Our solution ensured accurate and repeatable drilling and routing across all units.

2. Dual-Process Tooling with Servo-Driven Indexing

For sections that required both drilling and routing, we integrated Suhner modular units with specific tool bits. These units were mounted on servo-actuated X-Y slides, which enabled precise, programmable positioning. This step eliminated the need for manual repositioning and reducing cycle time.

3. Quick Changeover for Two Variants

To support both standard and extended panel versions, drill units were mounted on slider mechanisms with a built-in changeover feature. The operator can switch between variants by repositioning the units. No tool changes required. This minimized setup time and kept operations consistent.

4. Designed for Tight Cycle Time

With a target cycle time of 160 seconds per panel, every element of the design was optimized for speed and efficiency. Reusing drill units across variants, shortening tool travel paths, and automating movement through servos allowed us to meet this production requirement without compromise.

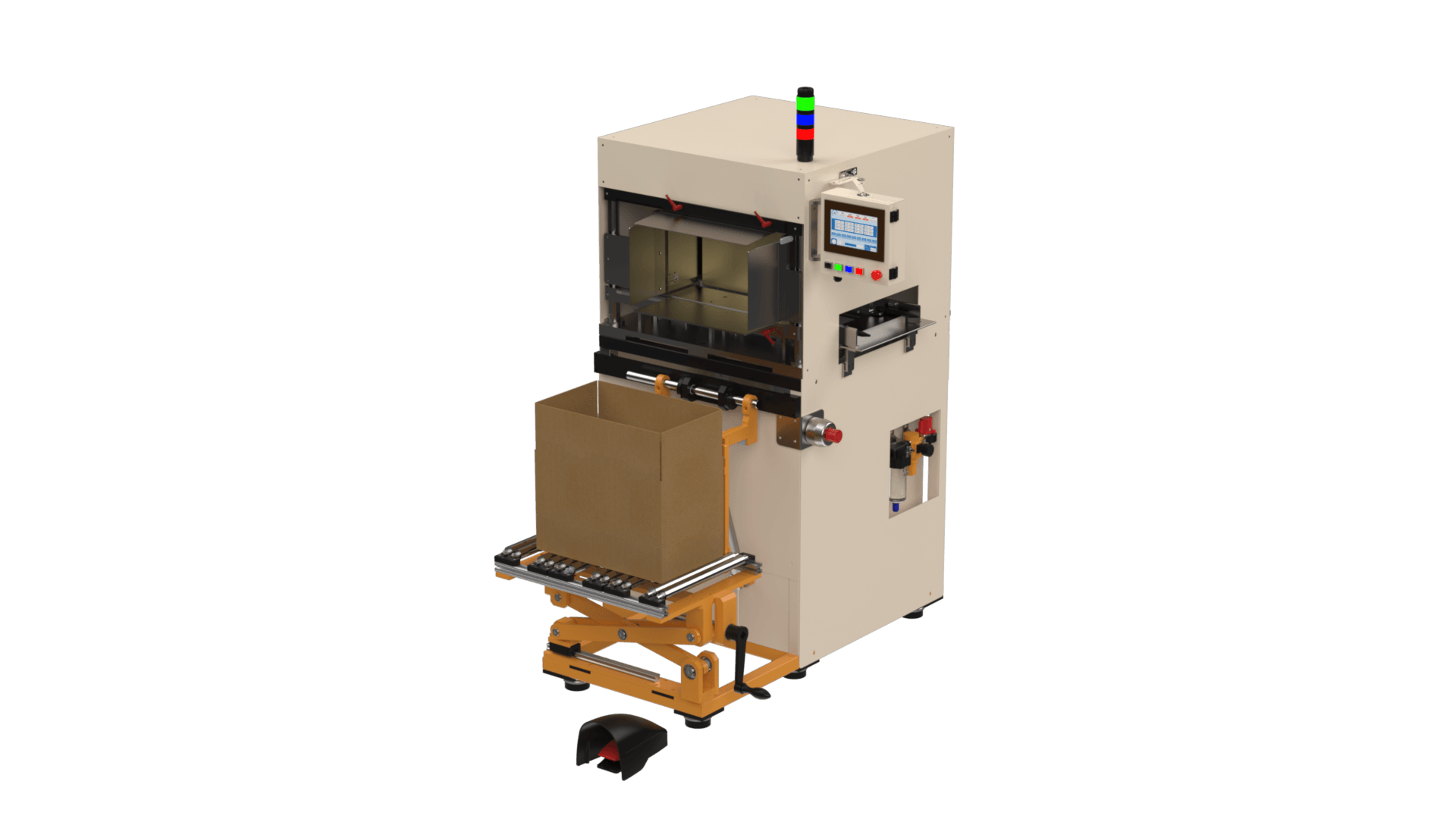

5. Integrated, Shop-Floor-Ready Machine Base

The entire fixture and tooling system was mounted on a custom frame that housed electrical panels, servo drives, maintenance doors, and a dust collection manifold. This compact structure simplified installation and ensured operator access and reduced downtime.

This special purpose machine was designed with DFM (Design for Manufacturing) and DFMEA (Design Failure Mode and Effects Analysis) to ensure it’s reliable, safe, and easy to maintain.

We delivered the final design to the client after validating it against all required safety and quality standards and performance criteria. We also ensured the design smoothly integrated into the client’s existing production line, minimizing disruption and enabling quick setup.