Sedin's highly experienced engineers provide comprehensive support to the client at various stages. Addressing the challenges posed by heavy structural designs for overhead cranes and other complexities, our design solutions assist the client in completing and installing their products on time, presenting improved versions.

We categorized our solution in four phases:

1. Load Calculations

Before we began the design process, we assessed the operational requirements. This included evaluating static, dynamic and impact forces. We calculated dead load, live load, and also dynamic loads caused by motion, like acceleration, deceleration, and sudden stops. Horizontal lateral loads from trolley and bridge movement were also evaluated to maintain stability.

Bending moments and deflection were considered in the design to prevent excessive bending and maintain stability under load. A safety factor of 1.5 was applied to ensure the crane could handle unexpected stresses and operate efficiently. Every calculation was carefully reviewed to confirm the design can safely handle the expected loads.

2. Detailed Design

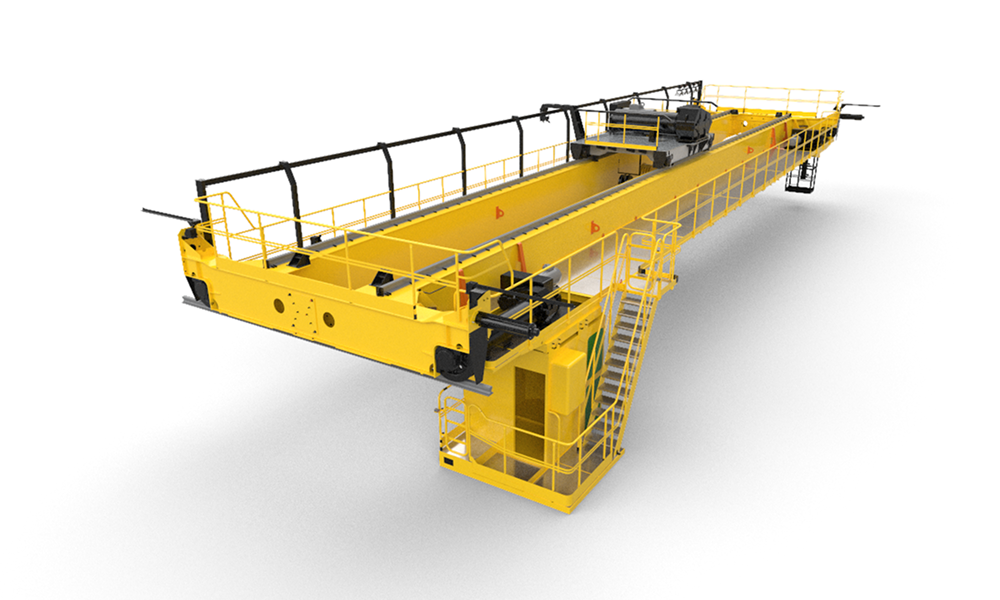

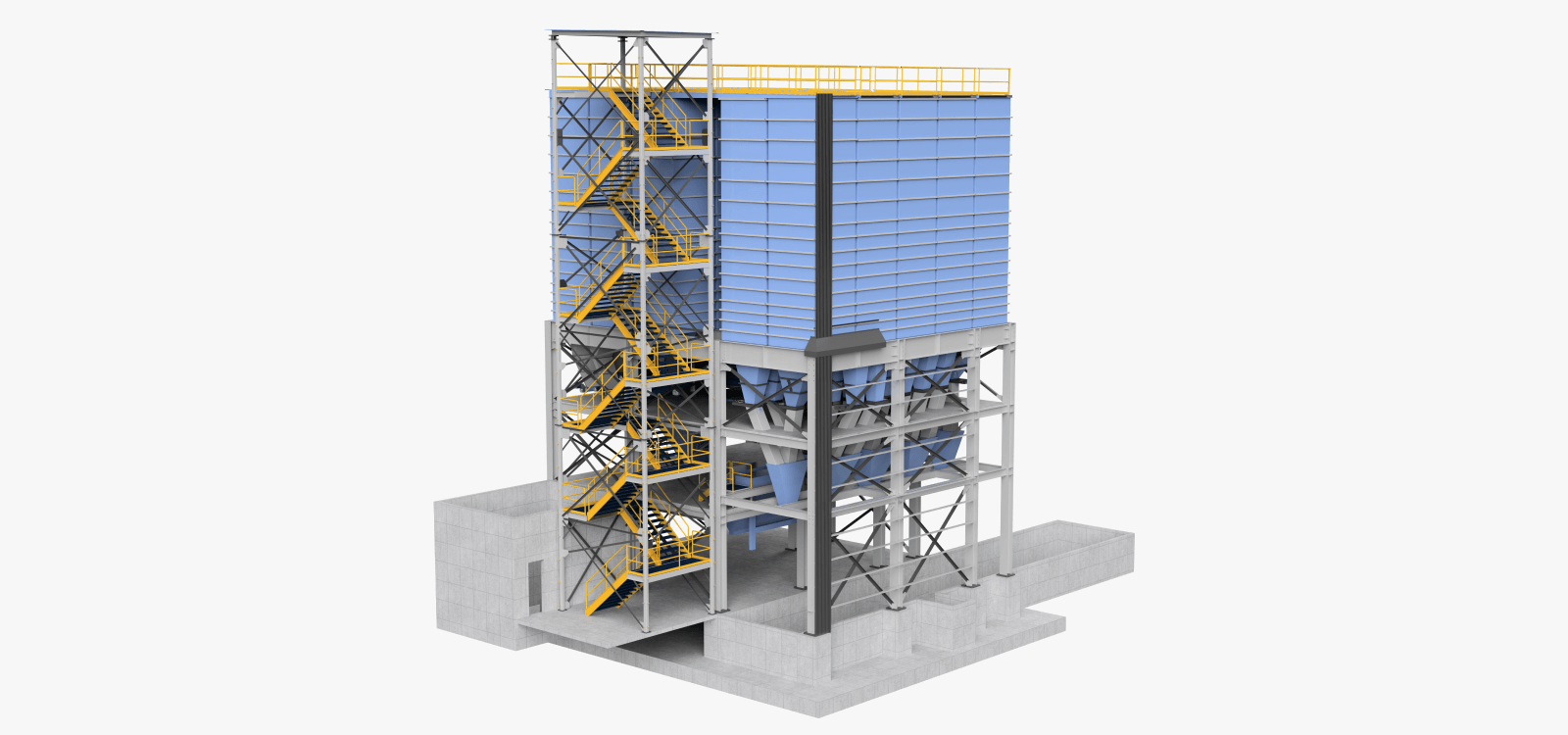

In this phase, we designed a 3D CAD model of the overhead crane using SolidWorks. It featured a 64-ft span and a 20-ft maximum lifting height, as per client’s requirements. Based on load calculations, we chose A572 Grade 50 (355 MPa Yield Strength) low-alloy structural steel for its strength and reliability.

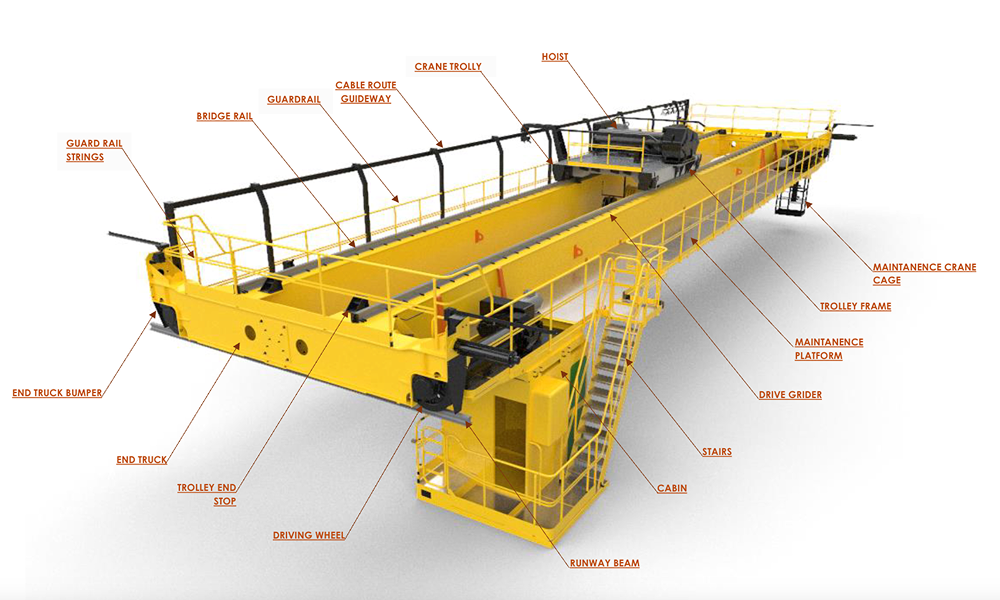

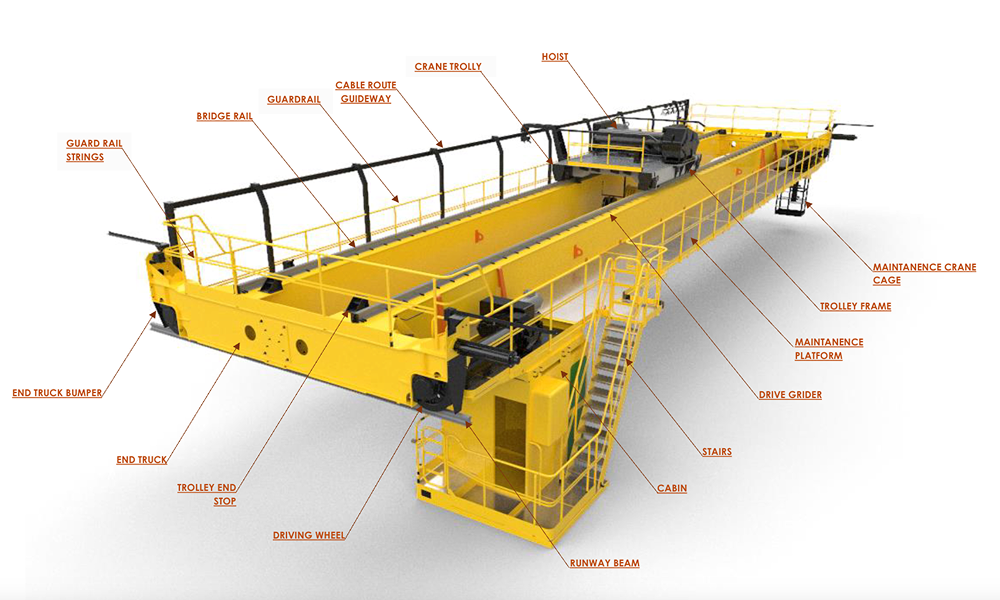

The key components of our overhead crane design included:

- Girder Bridge: The main structure was designed to support the crane’s load capacity while minimizing deflection. Its design ensured stability during lifting and movement, even under maximum load conditions.

- Trolley and Hoist: The trolley was designed for smooth travel along the bridge, supporting a hoist powered by a dual-speed motor for precise lifting and lowering. The hoist system also included a pick-and-place assembly to ensure accurate load positioning.

- Wheels and Tracks: We incorporated durable wheels with anti-friction bearings and precisely aligned tracks to ensure smooth movement and even load distribution.

- Drive Systems: High-performance motors paired with variable frequency drives (VFDs) were integrated to ensure smooth acceleration or deceleration and minimize mechanical stress.

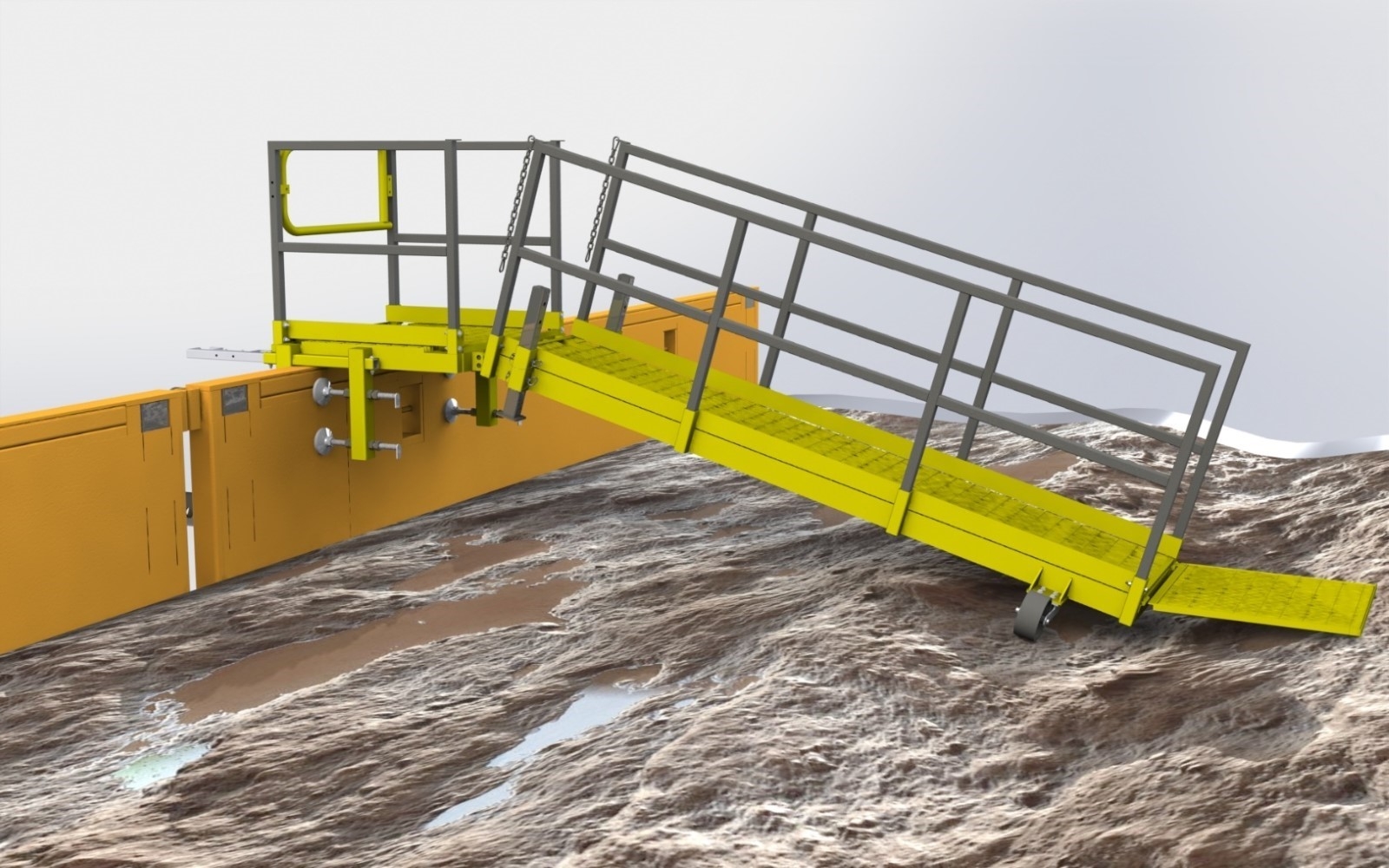

- Safety and Maintenance Access: Safety features, including overload protection, emergency stops, safety latches, brake system and an anti-sway system were integrated into the design. Walkways, ladders and platforms were added to allow easy access for maintenance and inspections of critical components.

3. Design Simulation and Validation

Several design simulations were conducted using SolidWorks to test the crane’s performance, focusing on key components like the girder bridge, trolley, hoist, wheels, and tracks. These simulations helped ensure the crane could handle the expected loads and operational conditions.

After the simulation, the design was validated to ensure compliance with relevant ANSI and ASTM standards for safety and structural integrity. We also made sure the design was customized to fit the available space, align with existing rail systems, and meet the required span, height, and lateral travel dimensions.

4. Final Review and Transfer

Once validated, the design underwent a final review. Assemblies and weldments were checked using DFMA techniques, while DFMEA ensured the reliability of the assembly structure. We also reviewed safety features on walkways and platforms to ensure compliance with OSHA standards.

The final design was confirmed with precise dimensioning, GD&T, flawless weldments, and a comprehensive quality checklist. We transferred the final design to the client, along with the deliverables, which included detailed 2D and 3D models in the required formats, a detailed Bill of Materials (BOM), and specifications for welding, nuts, bolts, and other critical components.

Our value-driven approach and expert structural design services ensured that the client received the deliverables on time, fully meeting their requirements with exceptional precision. This not only guaranteed the highest quality but also provided long-term value and reliable performance.