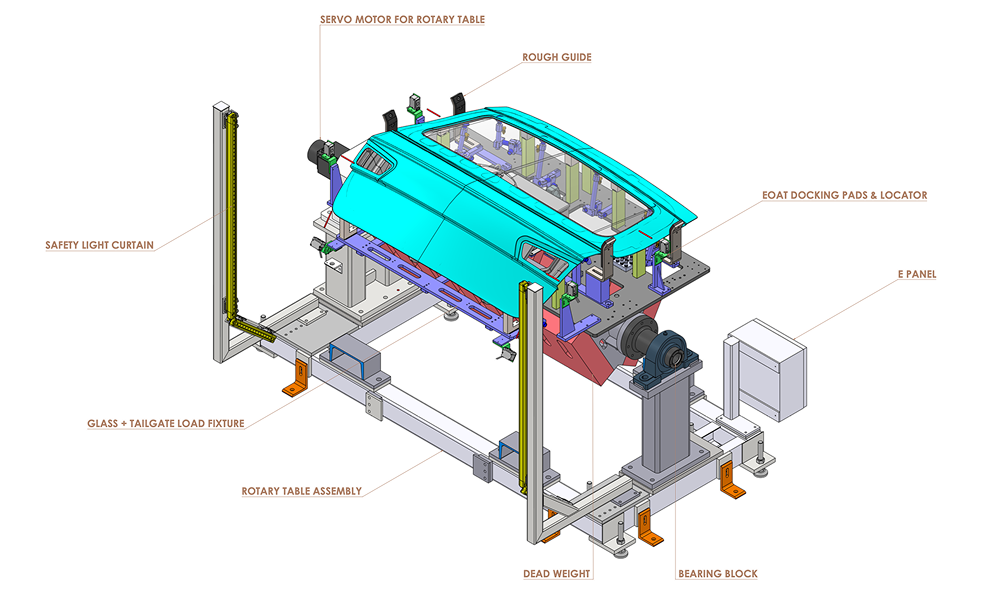

The client sought us to design a flipping station with a custom fixture to safely handle a glass and tailgate assembly during automated handling. As a future scope, the client also required the system to be flexible enough to handle different automotive models using interchangeable fixtures.

Automotive Assembly Line

Rotary Indexing Table Design for Tailgate and Glass Handling

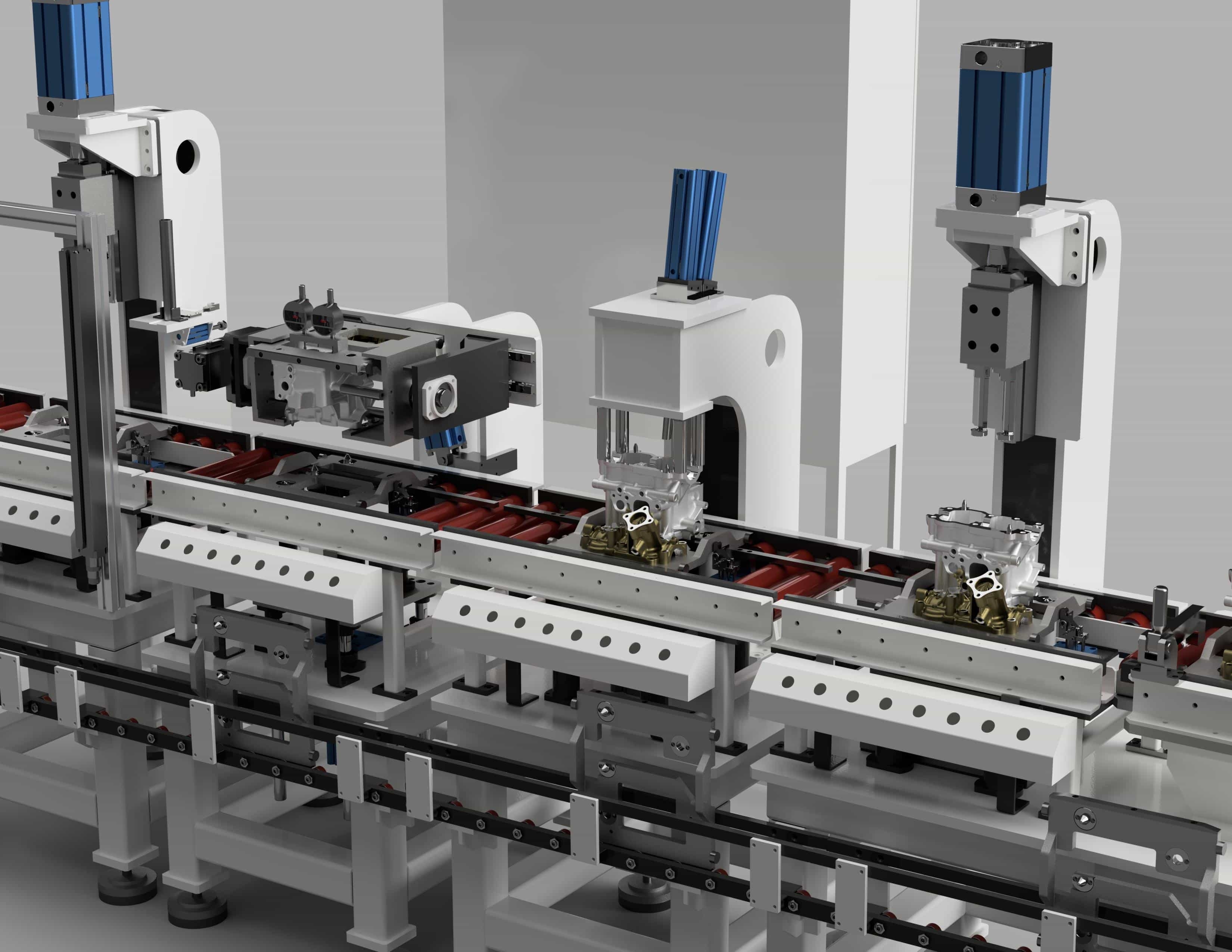

The client specializes in the design and manufacture of fully integrated totally automated systems, stand-alone assembly machines, specialized machines and automated & secondary equipment. Their end user is a global automotive OEM, requiring high-throughput automation solutions for their vehicle assembly line.

Scope

Challenge

- Glass Handling Safety: Designing a fixture that could securely hold both the glass and tailgate during flipping, without causing any cracks, scratches, or pressure marks.

- Unbalanced Load Distribution: Managing the weight imbalance between the glass and tailgate to ensure smooth and stable flipping.

- Future Compatibility: Ensuring the fixture design could be easily adapted for different automotive models as required by the client in future.

- Weight Limit Constraint: Keeping the total weight of the fixture and part assembly under 250 kg, while maintaining structural integrity and reliable performance.

Solution

The client initially approached us to design a flipping station with a fixture to handle a specific glass–tailgate assembly.

But during early discussions, we learned they planned to handle more part variants in the future. So instead of designing a single-use fixture setup, we proposed a 3-axis rotary indexing table that could accommodate up to three fixtures, giving the client more flexibility with minimal future investment.

Our team studied load constraints, model variants and layout feasibility to create an optimized solution. This proactive approach helped the client:

- Avoid repeated investments in future setups

- Speed up cycle time and reduce changeovers

- Plan for long-term growth without rework

Leveraging our expertise in industrial automation solutions, our design team created a 3D model that met all requirements and design standards.

Here’s how we approached the design and developed a solution that met both current needs and future goals:

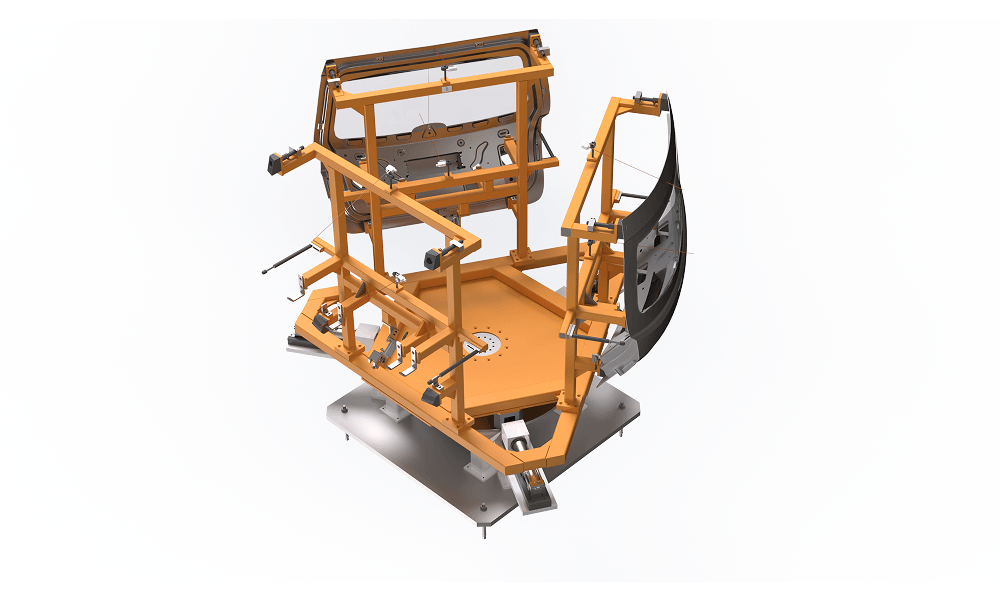

1. Fixture Designed for Safe and Precise Handling

We started by designing a custom fixture tailored to the current glass–tailgate combination. Our main focus was protecting the glass during flipping while ensuring accurate alignment and support.

Key design features:

- Nylon rest pads were added at all glass contact points to prevent scratches, cracks, or pressure marks.

- Ten vacuum cups were strategically positioned to evenly distribute the tailgate’s weight.

- Two clamping units were included at the bottom to ensure the part remained secure during flipping.

- Guiding blocks across the fixture width helped operators easily align the tailgate before loading.

This setup ensured reliable part handling without damaging the fragile glass, even during flipping.

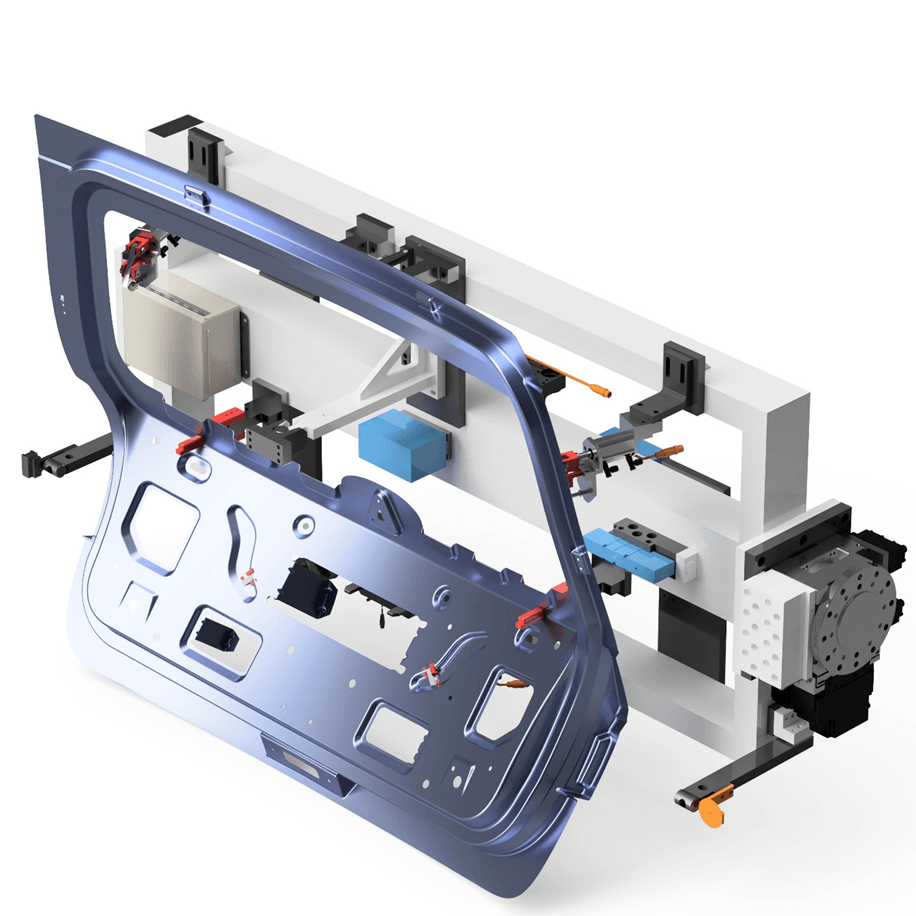

2. Rotary Indexing Table Designed for Flexibility

To accommodate future model variations, we designed a 3-axis rotary indexing table capable of holding three fixtures at once. These were arranged in a triangular layout, allowing each fixture to rotate independently without interference.

Design highlights:

- The table was designed to carry up to 900 kg, including fixtures and parts, with a proper factor of safety.

- A servo motor was integrated to enable precise and smooth rotation to support automated assembly.

- For the current setup, we designed one fixture to hold the glass–tailgate combo, while the other two stations were fitted with counterweights to maintain balance.

In future scenarios, these counterweights can be replaced with two additional fixtures to handle different models, increasing productivity without redesigning the base structure.

3. Presence Detection and Docking Interface

To verify correct part placement before rotation, the system included 4 distance sensors to detect the presence of both the tailgate and the glass. This ensured safe operation and prevented accidental motion without parts.

The fixture also included a locating and docking assembly for proper alignment with the robot’s End-of-Arm Tooling (EOAT). This enabled precise pick and place operations.

4. Compact, Line-Friendly and Serviceable

We kept the entire system compact enough to integrate into existing automotive assembly lines. Our modular fixture design allowed quick changeover and easy maintenance, while the use of standard components and open access points ensured serviceability with minimal downtime.

Our team ensured the equipment is simple and user-friendly. It can be conveniently combined with any application and fixtures can be upgraded for future requirements.

5. Design for Manufacturability and Compliance

All the safety and ergo standards were met as per the end client’s standard. We designed and modeled the rotary indexing table along with fixture while taking all the DFMEA (Design Failure Modes and Effects Analysis) into consideration.

With the help of Sedin’s cost effective and state-of-the-art idea, the entire machine was able to work continuously without any hassles and thereby increasing productivity.

Value and Benefits

Instead of a single flipping station with one fixture as initially planned, our rotary indexing table solution enabled the client to handle two additional models within the same cell. This helped them save costs and floor space by eliminating the need for separate setups.

Soft pads and vacuum cups ensured safe glass handling without damage, lowering rejection rates.

The compact design helped the client save floor space, reduce costs and improve productivity.

Designed for 900 kg with factor of safety, the system delivered long-term reliability and smooth integration into the automated line.