To solve the issues with the tower crane, we used a hands-on approach, combining research and practical structural engineering solutions to develop a detailed 3D model.

Our process included:

1. Load Calculations

Before jumping into the design, we made sure to understand the operational needs of the crane. This meant assessing the static and dynamic forces, considering weight, movement, and how lifting and lowering loads at different angles could impact stability.

We also considered important load types like dead, live, wind, seismic, and fatigue loads. This helped us explore various design options to ensure the crane would perform reliably, no matter the conditions.

2. Material Selection

Based on our load calculations, we chose EN 10025-3: S460 high-strength structural steel for the tower crane's main frame, jib, and other key structural components. This steel offers high strength and durability, even in low temperatures, while being lightweight yet strong (with a yield strength of 460 MPa).

For areas under the most stress, like crane’s joints and connections, we selected S460NL and S460ML, which are designed to withstand higher levels of pressure and strain.

3. Detailed Structural Design

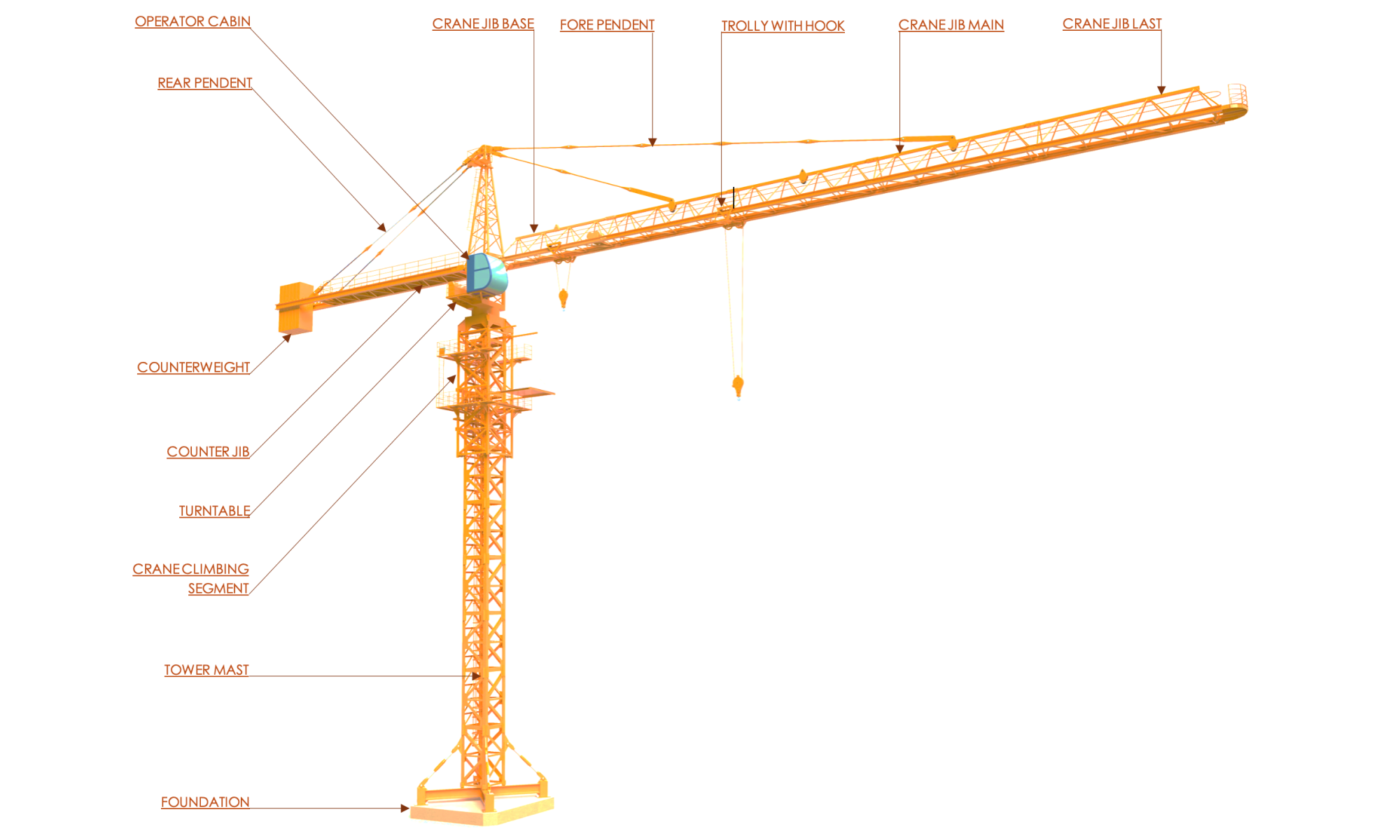

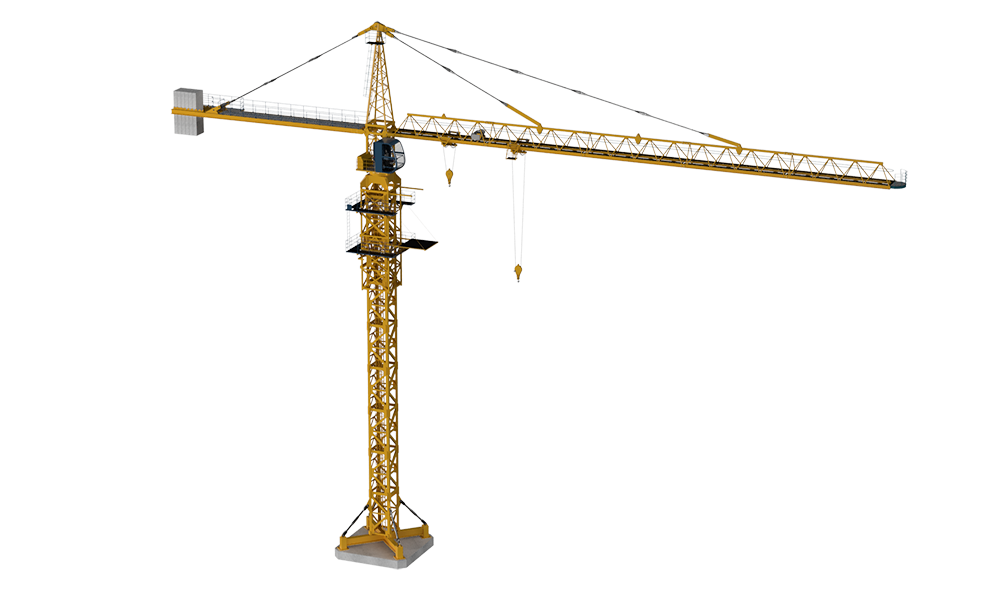

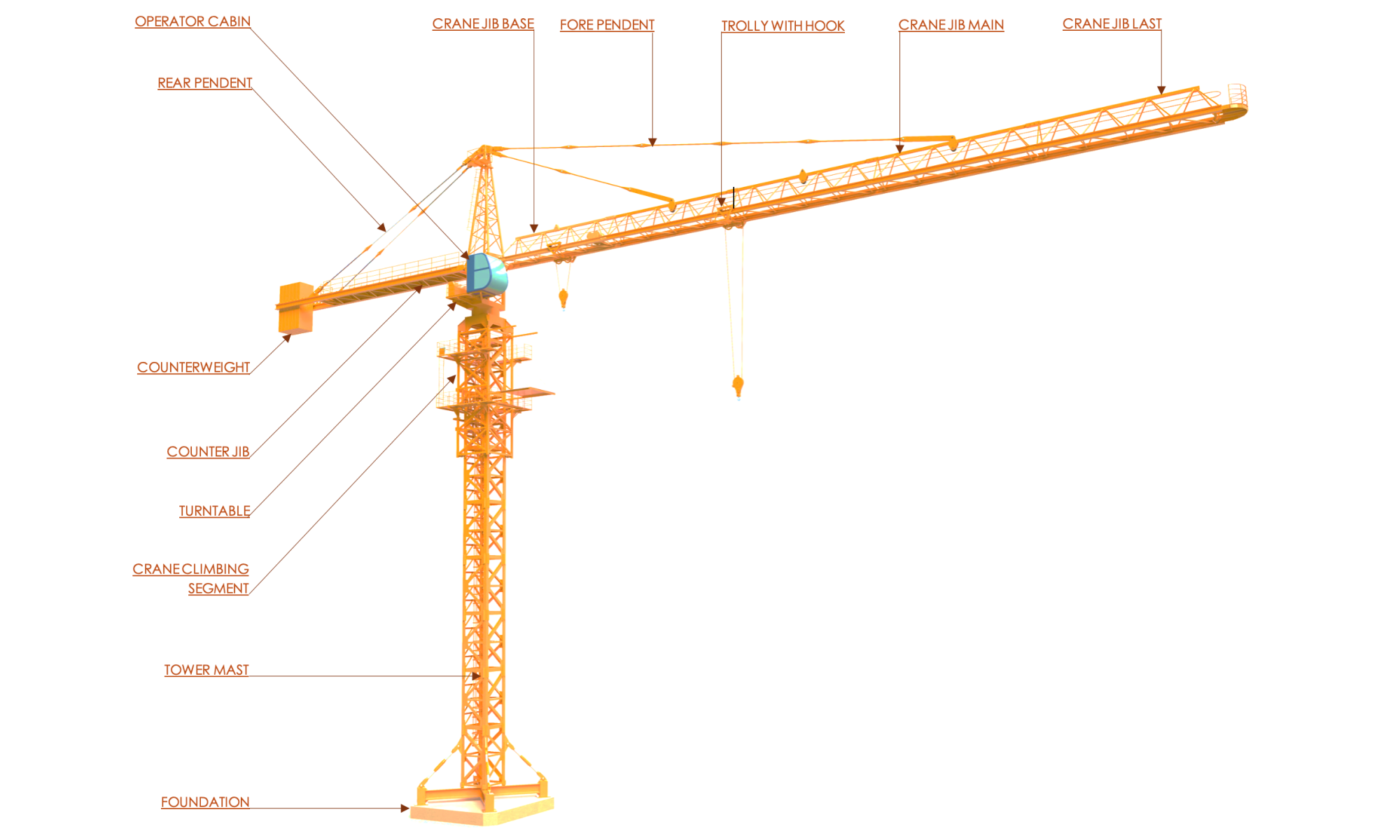

In this phase, we created a detailed 3D CAD model of the tower crane using SolidWorks.

Here are some of the key design elements:

- Tower Mast: We went with a modular lattice design for strength and easy transpor

- Jib (Horizontal Arm): Designed to handle heavy lifting without bending, reinforced to avoid stress points, and built with lightweight materials to keep the crane balanced.

- Counterweights: Placed strategically to prevent tipping, made from concrete-filled steel blocks for extra stability.

- Hoisting Mechanism: A high-capacity pick and place system was incorporated with safety backups to ensure smooth and secure operation.

- Base and Anchoring System: A solid bolted foundation to keep the crane steady.

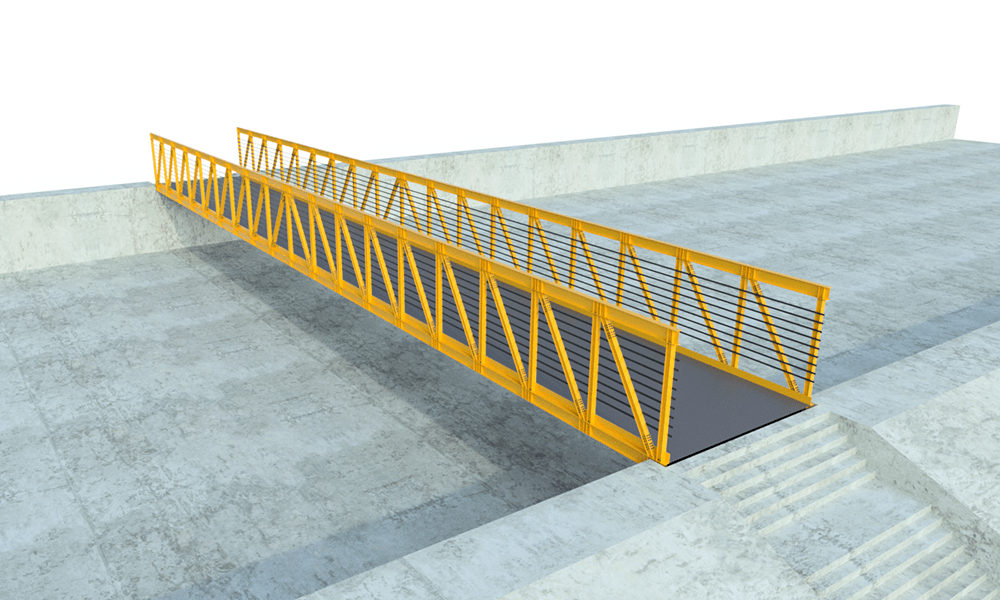

- Safety Features: We also added lifting attachments, walkways, stairs, handrails, and access equipment, all designed for functionality and safety.

After multiple iterations in CAD software, we developed a winning tower crane design. We ensured the final design was optimized for stability, balancing overturning forces, deflection, and vibration control.

4. Design Validation and Analysis

The final crane design was validated through basic analysis using SolidWorks Simulations. We tested the counterbalance weight, foundation, anchorage, and jib design. The analysis ensured the structural integrity, mounting arrangements, and lifting attachments were all functional and met real-world conditions.

5. Quality Check and Compliance with Standards

Before delivering the CAD files to the client, we thoroughly reviewed the design for quality and accuracy. New assemblies and weldments were verified using DFMA (Design for Manufacturing and Assembly) to ensure a high-quality, cost-effective solution. We also conducted DFMEA (Design Failure Mode and Effect Analysis) to identify and mitigate potential risks.

Our team ensured that all weldment assemblies and structural components adhered to AS standards for steel structures, while AISC guidelines were followed for fabrication and connections.

Additionally, all internal ladders, handrails, walkways, and access platforms met OSHA safety standards, including fall protection and toe plates for ladders.

The designs were finalized with proper GD&T (Geometric Dimensioning & Tolerancing), flawless weldments, and a detailed quality checklist.

By addressing the challenges of heavy structural designs, we helped the client complete and install their products on time, presenting the best solutions.