After a series of in-depth discussions with the client and a detailed review of their floor plan, operational flow and safety requirements, Sedin Engineering team developed a custom turntable system designed for efficient handling of glass-fitted tailgates.

Leveraging our strong expertise in industrial automation services for material handling, we designed a solution that focused on safety, accuracy, compact size and weight limits, while also making sure it could be easily upgraded in the future.

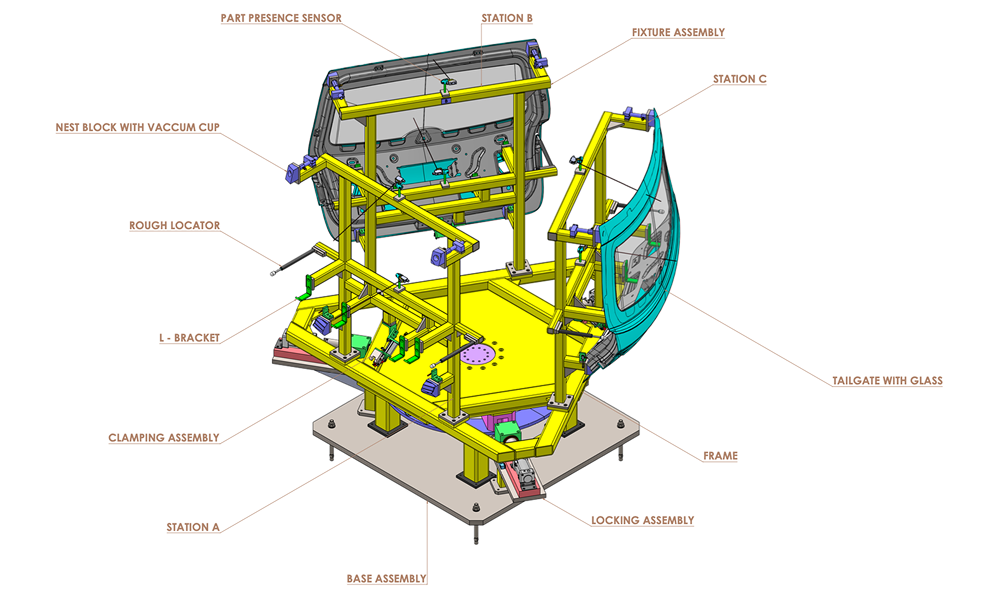

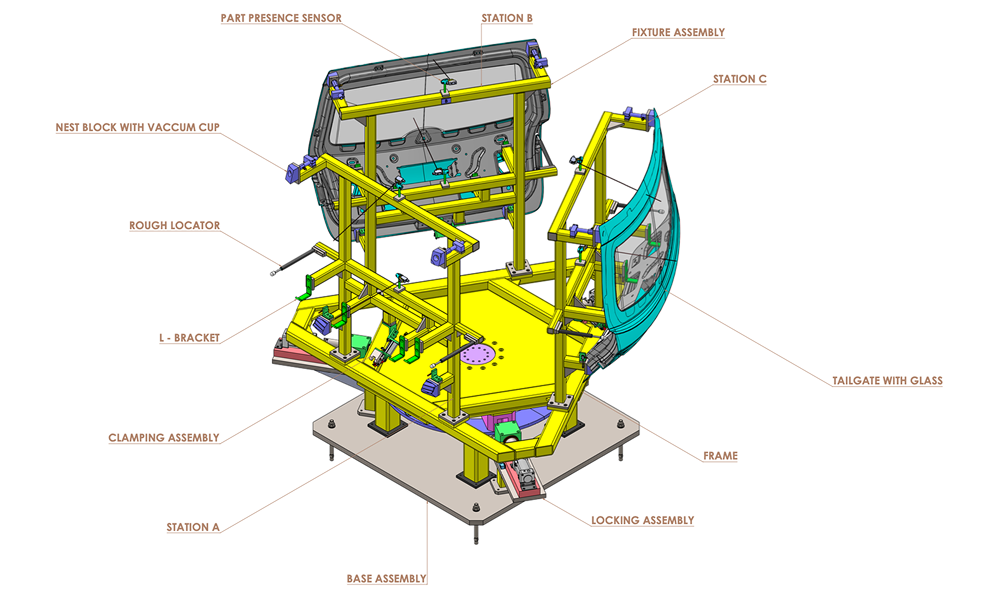

1. Compact Turntable Frame with Triangular Layout

To meet the strict space constraints of the client's factory, the turntable was designed in a triangular configuration, enabling three working stations within a minimal footprint. This geometry not only reduced rotational travel between stations (120° indexing) but also provided stable weight distribution and easy operator access on all sides.

The frame was designed for strength-to-weight optimization, supporting the fixture assemblies while maintaining structural integrity under repeated dynamic loads.

2. Three-Station Fixture Assembly Design

In the fixture assembly, Station A was designated to load the tailgate with glass, Station B was for inspection and Station C was for unloading the finished part. Each of these three stations had the same fixture setup. This made the process simpler and reduced the need for additional training or setup changes. The fixture design included:

- Four precision-machined nest blocks to hold the tailgate in place

- Two vacuum cap systems for gentle handling and support of the glass panel

- Four mechanical hooks and a clamping assembly to firmly secure the tailgate without inducing stress or distortion

- A rough locator for easy initial positioning

- A distance sensor to detect and verify the presence of the tailgate and glass assembly

These features ensured repeatable positioning, minimal operator effort and damage-free handling, even in high-throughput environments.

3. Safety-Locking and Sensor Integration

To ensure complete positional accuracy and prevent movement during manual handling or inspection, an external locking assembly was integrated at each station. This lock is sensor-monitored using proximity switches, ensuring the turntable is fully secured before any operation is initiated. This feature meets the client’s safety and foolproofing requirements, reducing the risk of accidental rotation or misalignment during the process.

4. Motor-Gearbox Selection with Built-In Future Capacity

The turntable was powered by a high-torque motor and precision gearbox carefully selected to handle the complete system load of 1.2 tons. Importantly, the drivetrain was sized with an additional 100 kg capacity in mind. This allowed the client to integrate future components or upgrades without overloading the system.

Before finalizing the turntable design, our team considered the following factors:

- Required torque at each indexing point

- Speed and acceleration profiles

- Duty cycles and load inertia

- A standard factor of safety (FOS) for all real-world conditions

This proactive approach ensured long-term reliability with zero risk of performance degradation.

5. Compliance with DFMEA, Ergonomics and Client Standards

All components and assemblies were validated through a thorough Design Failure Mode and Effects Analysis (DFMEA) process, reducing the chance of in-field failure or rework. The entire system was also reviewed against the client’s ergonomic and safety standards, ensuring:

- Easy operator access and minimal bending/reaching

- Clear line-of-sight for inspections

- Sensor-driven safety interlocks at all critical points

Additionally, the weight distribution and fixture ergonomics made it easy for operators to handle components without fatigue. This contributed to a safer and more efficient work environment. With the help of Sedin’s cost-effective and state-of-the-art idea, the entire machine was able to work continuously without any hassles, thereby increasing productivity.