The electric vehicle (EV) revolution is here and it's gaining speed. But there’s a catch: battery assembly can't keep up with the demand. As the race to produce EVs intensifies, many manufacturers are struggling to scale production fast enough.

The solution? A battery assembly line that’s fast, flexible and automated. In this blog, we’ll explore how smart design and automation can help you break through the bottleneck. You’ll discover how effective mechanical design and controls engineering can transform your assembly line boosting efficiency and preparing you to meet the growing demand.

Let’s explore how the right industrial automation solution can supercharge your battery manufacturing process.

Top Challenges for Battery Manufacturers

Battery manufacturers are under intense pressure. As EV demand surges, so does the need to deliver high-quality batteries. Faster than ever.

Here are the key pain points manufacturers are dealing with:

- Production Bottlenecks: Existing EV battery assembly lines can’t keep up with the rapid changes in battery chemistry and pack designs.

- Labor Shortages: It’s tough to find skilled workers who can keep pace with increasingly automated environments.

- Inconsistent Quality: With growing demand, quality control can slip, leading to defective batteries that affect safety and performance.

- Regulatory Compliance: Dealing with safety rules and certifications makes things even more complicated.

- Rising Demand: Meeting the increasing order volumes from the EV and ESS sectors while maintaining quality and speed is a major hurdle.

These challenges aren’t going away. So, how do you overcome them? The solution lies in optimizing your EV battery assembly line with efficient design and automation. Let’s take a closer look at what a battery assembly line really involves.

What is a Battery Assembly Line?

A battery assembly line is a system that puts together different parts of a battery, like cells, tabs and modules, into a complete unit. It uses machines, robots and automation to handle tasks like stacking cells, welding connections and running safety checks.

These lines are designed to work fast, reduce human error and maintain consistent quality. They're widely used to produce batteries for electric vehicles (EVs) and energy storage systems (ESS).

What is Inside a Battery Assembly Line?

A battery pack assembly line involves several key steps to ensure the final product is safe, high-performing, and ready for use. Here's a breakdown of the main operations:

- Cell Testing and Sorting: The first step is to test and sort the battery cells. Only the best-performing cells move forward to ensure high-quality output.

- Stacking and Insulation: Next, the cells are carefully stacked with separators and insulators. This helps prevent short circuits and ensures safe, efficient operation.

- Welding and Connections: Laser welding and busbars are used to connect the cells into a unified pack, forming the heart of the battery’s electrical system.

- Electronics and Sensors: Essential electronics, including thermistors, PCBs, and control systems, are added to monitor and regulate the battery's performance throughout its life.

- Final Assembly and Inspection: The pack is then enclosed, labeled and rigorously tested to ensure it meets all standards before being ready for shipment.

Key Features of a Modern Battery Assembly Line

Here’s what a modern, high-performance battery pack assembly line should deliver:

1. Flexibility

Battery designs are always changing. One day you're making lithium-ion batteries, the next it could be solid-state. Your line should be able to switch between different types and sizes without costly downtime or major changes. That way, you stay ready for whatever comes next.

2. Traceability

You should always know where every battery part came from and how it was made. This helps with quality checks, safety and following the rules. A good, automated battery assembly line keeps track of everything from start to finish so nothing gets missed.

3. Safety

Working with batteries can be risky. There are fire hazards and high voltages involved. A modern assembly line includes safety features like fire suppression, safe material handling and automatic inspections. These keep your team and your products safe.

4. Efficiency

Speed is important but so is doing it right. Automation helps you assemble batteries faster and better. Robots, cameras and testing systems help cut down on mistakes, lower your costs and keep quality high.

5. Staying Ahead of the Competition

Having a smart, automated assembly line helps you grow faster and deliver on time. It shows customers you’re serious about quality and ready to meet demand. In a competitive market, that can make a big difference.

How Smart Design and Automation Optimize Your Battery Assembly Line

Creating a high-performance battery pack assembly line requires two crucial elements: mechanical design and controls engineering.

A. Mechanical Design: The Foundation of Scalable Assembly

Mechanical design is where optimization begins. A well-thought-out line layout and equipment setup can significantly reduce downtime, improve throughput and smoothly support future tech upgrades. Here's how:

- Modular Architecture: Designing with modular systems allows you to adapt quickly when new battery formats or sizes hit the market, without expensive overhauls or retooling.

- Custom Fixtures and Tooling: Tailored fixtures reduce operator dependency, ensure consistent part placement, and speed up assembly. This is especially important in high-precision EV battery manufacturing.

- Automated Material Handling: Smooth, safe movement of fragile components like cells and tabs is important. Automated conveyors, lifters and robotic arms reduce damage and keep lines running smoothly.

When you integrate flexibility into your mechanical design from the start, your battery assembly line is ready for the future and can scale with minimal disruption.

B. Controls Engineering: Turning Machines into Intelligent Systems

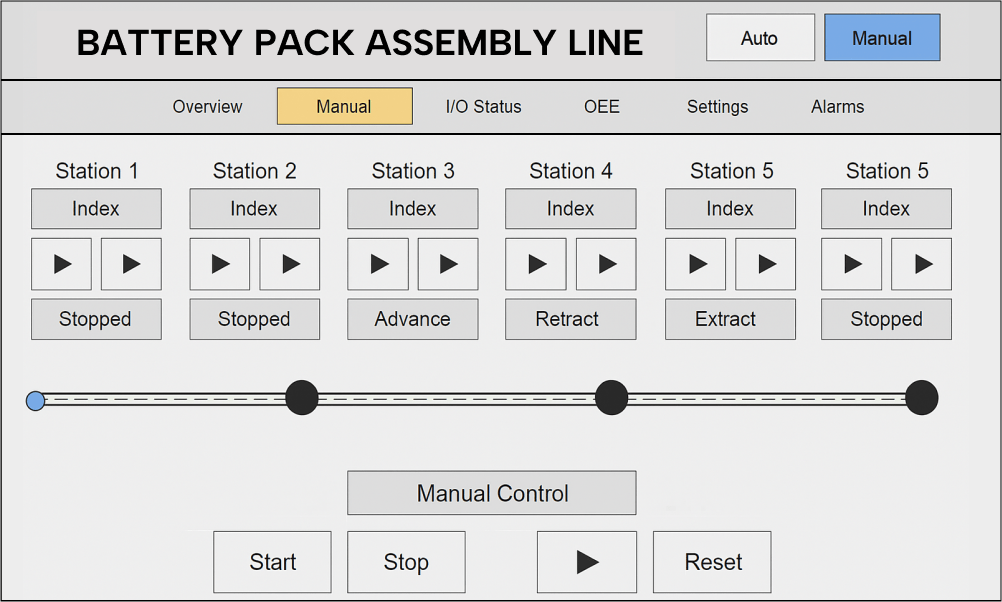

Controls engineering transforms your battery assembly line from automated to intelligent. This is the key to optimizing performance, reducing errors and gaining real-time insights across the entire process.

- Real-Time Monitoring and Data Collection: PLCs and SCADA systems give you a live view into your line’s performance. This helps you catch issues early, reduce downtime and make smarter decisions faster.

- Vision Inspection Systems: Automated visual checks ensure that every battery cell, tab and weld meets exact standards. This way, you maintain high quality without slowing down the assembly line.

- MES Integration: A Manufacturing Execution System connects machines, workers and data. It improves traceability, simplifies compliance reporting and eliminates the inefficiencies of manual logging.

Together, mechanical design and controls engineering form the backbone of an optimized battery manufacturing automation line that’s flexible, smart and ready to grow as your needs change.

Automated Battery Pack Assembly Lines for EV and ESS Applications

To meet the rising demand for both Electric Vehicle (EV) and Energy Storage System (ESS) batteries, it's important to consider how assembly lines can handle the unique requirements of both types of batteries.

While both types rely on similar automation and smart design principles, having a single assembly line for both EV and ESS batteries is generally not advisable due to several key differences between them.

Key Differences Between EV and ESS Batteries

Battery Size and Capacity

⇾ EV Batteries are typically designed for high power output in compact, lightweight formats that fit within a vehicle.

⇾ ESS Batteries, on the other hand, require much larger capacity for energy storage, meaning they’re larger, heavier, and have different power needs, primarily designed for long-duration energy discharge.

Cooling and Safety Systems

⇾ EV Batteries often use liquid cooling systems designed for fast charge and discharge cycles.

⇾ ESS Batteries need more robust cooling systems to handle long-duration energy storage cycles, and they also require extra safety protocols due to their larger capacities.

How Smart Design and Automation Help

To meet these varied needs, smart design and automation solutions are crucial to improving the manufacturing and assembly of both battery types. Here’s how:

Modular Assembly Lines

A modular assembly line helps manufacturers quickly adapt to producing and assembling both EV and ESS batteries. These flexible systems can be easily adjusted or reconfigured which reduces the need for costly retooling or downtime.

Customized Cooling Systems

Automated cooling systems can be customized to meet the needs of both EV and ESS batteries. EV batteries require fast cooling for quick charge/discharge cycles, while ESS batteries need cooling solutions that efficiently manage heat for long-term storage.

Battery Recycling and Sustainability: A Key to Future-Proofing Your Battery Assembly Line

Sustainability is no longer optional; it's essential. Battery recycling is a crucial part of that shift. By incorporating automated systems into your assembly line, you can easily recover valuable materials like lithium, nickel and cobalt.

Smart engineering design plays a key role in making recycling part of the process. With flexible, modular designs, you can add recycling capabilities without slowing down production.

Reliable automation solutions ensure the process is efficient, reducing both waste and production costs. This approach helps you stay ahead of industry demands.

By optimizing your assembly line with recycling, you’ll be able to produce high-quality batteries while minimizing environmental impact.

The Long-Term Value of Battery Assembly Line Automation

Do you feel industrial automation is just about speeding things up? It’s much more than that. For battery assembly lines, it lays the foundation for long-term growth, consistent quality and the ability to scale with demand. Here's why:

1. Reduced Operational Costs

By automating key parts of the assembly process, you can significantly cut down on labor costs and human error. With predictive maintenance and real-time monitoring, your line will experience less downtime. This means more production with fewer disruptions.

2. Faster Time to Market

Automated systems allow you to increase production speed without sacrificing quality. This means faster turnaround times on orders and the ability to respond quickly to shifts in the market.

3. Ongoing Support and Maintenance

Automation doesn’t stop at installation. Having a partner who offers continuous support ensures your assembly line stays optimized for years to come. Whether it's software updates, remote diagnostics, or operator training, ongoing support helps you stay ahead of the curve.

By investing in the right industrial automation partner, you're not just improving your current production process — you're future-proofing your business for continued success.

Why Choose Sedin to Design and Automate Your Battery Assembly Line

Scaling your battery production for EVs and energy storage systems takes more than just equipment; it takes smart design and reliable automation.

At Sedin Engineering, we combine mechanical design with advanced controls engineering to create flexible, high-efficiency assembly lines built for today’s demands and tomorrow’s growth. From speed and quality to sustainability and scale, every solution is designed to move your business forward.

Looking for the best battery assembly automation partner? Contact us today.