When a critical machine part fails without CAD drawings or supplier support, production stops instantly. This is a familiar challenge for manufacturers and EPCs dealing with old machines, discontinued components, or undocumented systems.

The longer the downtime, the higher the costs.

Reverse engineering offers a practical solution. It captures a part’s geometry, dimensions, and material properties to create accurate digital models for manufacturing. The process can also improve the design, making parts stronger and more reliable. This keeps equipment running even when documentation is missing or OEM support is no longer available.

In this blog, we will learn more about reverse engineering – what it is, how it works, and how it supports modern manufacturing.

What is Reverse Engineering?

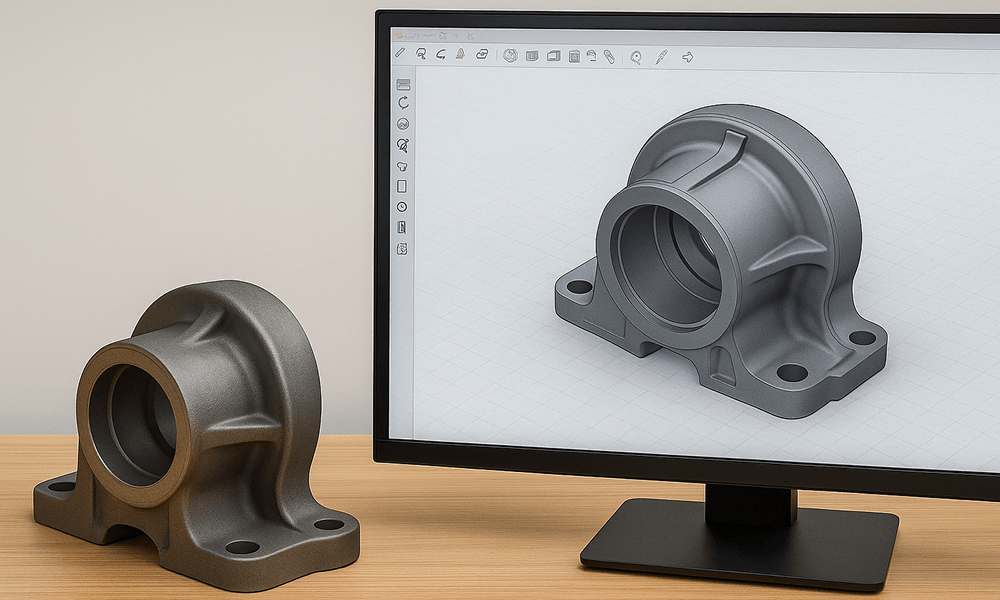

Reverse engineering is the process of taking a physical part and creating a digital model from it. The part is measured, scanned, or analyzed to capture its geometry, dimensions, and material properties. This data is then used to create accurate CAD models and technical drawings.

The goal isn’t just to copy a component. It’s to understand how it was designed and how it works. With that knowledge, you can manufacture replacements, improve performance, or even adapt the design for new applications.

Why Use Reverse Engineering?

Companies often ask, “Why should we use reverse engineering?” The answer is simple: it helps solve problems that come up when equipment is old, parts are no longer supported, or documentation doesn’t exist.

Instead of replacing entire machines or waiting on long OEM lead times, reverse engineering provides a faster, cost-effective way to get critical parts back into production. It also creates opportunities to improve designs and build reliable digital records for the future.

How Reverse Engineering Works

The reverse engineering process involves several practical steps. These steps help manufacturers and EPCs recreate or improve parts when documentation or OEM support is unavailable. Here’s the step-by-step process:

- Understand the Part and Its Function: At first, engineers study the component to know how it works and interacts with surrounding systems. Here, simply copying the part is not enough; functional understanding is essential.

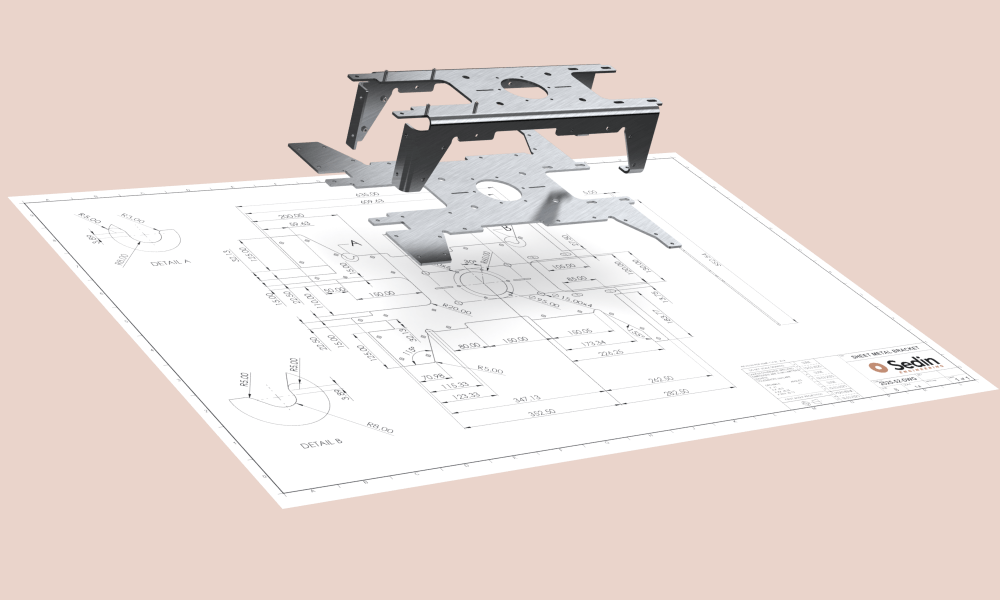

- Data Capture with 3D Scanning: 3D scanners, laser scanners, structured light scanners, and industrial CT scanners are used to capture precise measurements and complex geometries.

- Coordinate Measurement: Tools like calipers, micrometers, and CMM machines record exact dimensions, which are logged in databases to guide the modeling process.

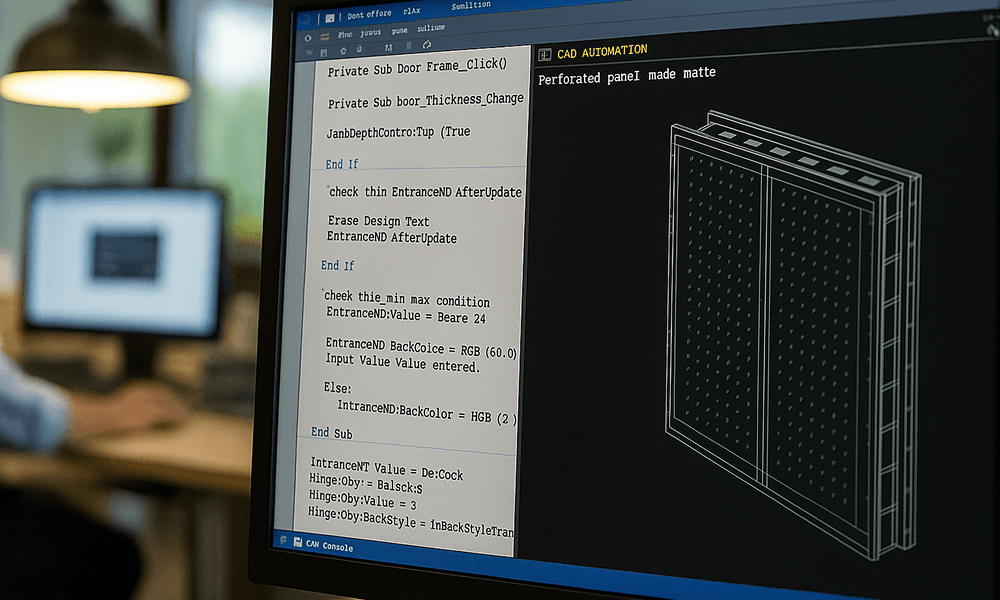

- CAD Modeling: Then, the captured measurements are converted into 3D CAD models. Engineers define geometry, tolerances, and material properties to make the part ready for manufacturing or analysis.

- Verification and Testing: The CAD model is checked against the original part to confirm fit, function, and accuracy. Prototypes may be produced for validation if needed.

- Documentation and Delivery: Final outputs include 3D CAD files, 2D drawings, BOMs, and specifications, providing everything needed for production or maintenance.

- Optional Design Improvements: With new digital models ready, engineers can strengthen weak areas, update materials, and redesign parts in line with Design for Manufacturing (DFM) principles to simplify production and boost performance and durability.

The reverse engineering process makes sure components are accurate, functional, and manufacturing-ready while also creating digital records that make future maintenance and upgrades easier.

Benefits of Reverse Engineering

- Recreate Obsolete Parts – Need a gearbox shaft or pump impeller that the OEM no longer supplies? Reverse engineering makes it possible to reproduce those critical components without waiting for discontinued parts.

- Reduce Downtime – Any delay in the manufacturing process can be costly. By recreating parts in-house or with a trusted Reverse Engineering service provider, you can get replacements faster and avoid stoppages that drag on for days or even weeks.

- Save Costs – Why replace an entire machine when only one component has failed? Reverse engineering lets you reproduce just the part you need, saving thousands compared to a full replacement.

- Improve Part Performance – Reverse engineering goes beyond just recreating parts. Weak areas can be reinforced, materials upgraded, and designs optimized. For example, a worn valve can be redesigned to last longer and handle higher loads.

- Create Digital Records – Every part can be captured as a 3D CAD model, giving you accurate digital files for future maintenance, retrofits, or system upgrades.

- Simplify Maintenance and Upgrades – With digital models on hand, technicians can plan repairs or modifications with confidence, instead of relying on trial-and-error at the shop floor.

- Enable Design Flexibility – Sometimes older components don’t match up with new equipment. Instead of starting new product development from scratch, reverse engineering helps you modify existing parts to fit the new equipment, saving both time and cost.

Applications of Reverse Engineering

Reverse engineering helps manufacturers, EPCs, and OEMs recreate parts, keep equipment running, and improve maintenance and production. Here’s how it’s used across industries:

- Manufacturing & Industrial Equipment – Rebuild worn-out components like pumps, gearboxes, and conveyors so production lines keep running without replacing entire machines.

- Automotive – Reproduce hard-to-find engine housings, brackets, and suspension parts to keep vehicles and heavy machinery operational.

- Aerospace & Defense – Recreate essential parts even when drawings or supplier support are missing, ensuring safety and compliance.

- Oil & Gas / EPC Projects – Replace valves, flanges, and piping quickly to simplify maintenance and reduce downtime.

- Tooling & Fixtures – Reproduce jigs, molds, and custom fixtures to avoid interruptions in factory operations.

- Product Development & Prototyping – Analyze competitor products, copy key features, or test design improvements before full production.

- Digital Twins & Maintenance Planning – Turn physical equipment into 3D CAD models to simulate performance, plan maintenance, and prepare for upgrades.

Choosing the Right Reverse Engineering Service

Selecting the right reverse engineering service can make a big difference if you want accurate part replication, faster turnaround, and cost-effective solutions.

The right partner can help you recreate legacy parts, optimize designs, and minimize downtime, all while using the latest 3D scanning, CAD modeling, and material analysis technologies.

Here’s what to look for:

- Experience in Your Industry – Providers who understand your machines, parts, and processes, whether automotive, aerospace, or EPC projects, deliver faster and more accurate results.

- Technical Expertise – Skilled engineers familiar with 3D scanning, CMM, CAD modelling, and material analysis ensure precise part reproduction.

- Proven Tools and Technologies – High-precision scanners, CT machines, and advanced CAD software are essential for reliable and accurate digital models.

- Quick Turnaround – Timely delivery helps reduce downtime and keeps production lines running smoothly.

- Flexible Manufacturing Support – Providers should offer CAD models, 2D drawings, or ready-to-manufacture parts, depending on your project requirements.

- Quality Assurance – Verification and testing processes ensure parts meet specifications and perform reliably in real-world applications.

- Design Improvement Capability – The best services aren’t limited to simply replicating parts; they suggest design improvements for durability, performance, and manufacturability.

Partner with Experts in Reverse Engineering Services

Ready to keep your machines running smoothly, reduce downtime, and recreate hard-to-find parts with confidence?

Sedin Engineering offers product design and reverse engineering services that help manufacturers, EPCs, and OEMs recreate essential parts, redesign unavailable components, and minimize costly downtime

Using advanced 3D scanning and CAD modelling, we create precise digital models that simplify manufacturing and save you valuable time.

Contact our sales team for accurate, ready-to-use designs and digital solutions tailored to your machines and processes.