Why Your Organisation Needs a Wiring Harness Designer

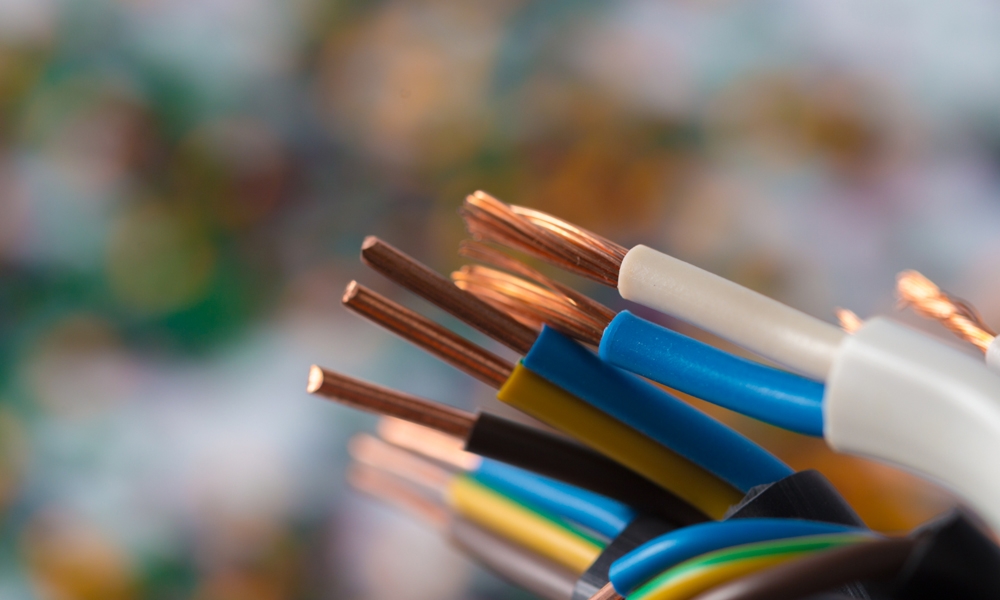

Wiring harnesses are essential components in numerous electronic systems, from automotive and aerospace to industrial machinery and consumer electronics. These harnesses connect various components, such as sensors, switches, and actuators, to a central control unit. Despite their appearance, designing wiring harnesses is a complex, time-intensive process.

This is where a wiring harness designer comes into play. Specialising in the design and development of wiring harnesses across various industries, these professionals possess the expertise to create custom solutions tailored to specific requirements.

In this blog, we'll explore the key reasons why having a wiring harness designer in your organisation is beneficial, the advantages they bring, and the challenges of managing harness design in-house.

Importance of a Wiring Harness Designer in Your Organisation

There are several key reasons why your organisation may need a wiring harness designer:

Expertise and Experience

Wiring harness designers have extensive knowledge and experience in designing and developing harnesses. They understand the intricacies of electrical systems and can create bespoke harnesses that meet your specific requirements. Their expertise ensures your wiring harness is reliable, efficient, and cost-effective.

Time and Cost Savings

Designing wiring harnesses in-house can be a resource-intensive process, requiring specialised tools, equipment, and expertise that may not be readily available. Outsourcing to a wiring harness designer can save time and reduce costs, streamlining the design and development process.

Customisation

Every organisation has unique requirements for their wiring harnesses. A wiring harness designer can deliver tailored solutions, whether for automotive, aerospace, or industrial applications, ensuring your harness is optimised for its intended use.

Quality Control

Wiring harnesses are critical components, and poor design can lead to performance issues, safety hazards, and costly repairs. A wiring harness designer ensures your harnesses meet stringent quality and safety standards, minimising the risk of malfunctions.

Support and Maintenance Wiring harness designers offer ongoing support and maintenance, ensuring that your harnesses remain in optimal condition. They can help troubleshoot issues as they arise, reducing downtime and keeping operations running smoothly.

Ensuring Proper Wiring Wiring harness designers are responsible for developing manufacturing documents and conducting quality tests, ensuring harnesses are built according to specific system requirements. This diligence helps prevent potential malfunctions or electrical hazards.

Meeting Industry Standards Wiring harness designers have a deep understanding of relevant industry standards and regulations, such as IPC/WHMA-A-620, ensuring compliance and enhancing the safety and reliability of your final product.

Design Flexibility A wiring harness designer can achieve the desired functionality and aesthetics of your final product, enabling your organisation to differentiate itself in the marketplace with custom solutions.

Conclusion In today's rapidly advancing technological landscape, the role of a wiring harness designer is more critical than ever. They not only ensure the safety, quality, and compliance of your wiring harnesses but also contribute to cost savings and enhanced design flexibility, ultimately setting your products apart in the market.

Hiring a skilled wiring harness designer is a strategic investment, helping your organisation stay competitive, achieve its goals, and consistently deliver high-quality products to your customers.