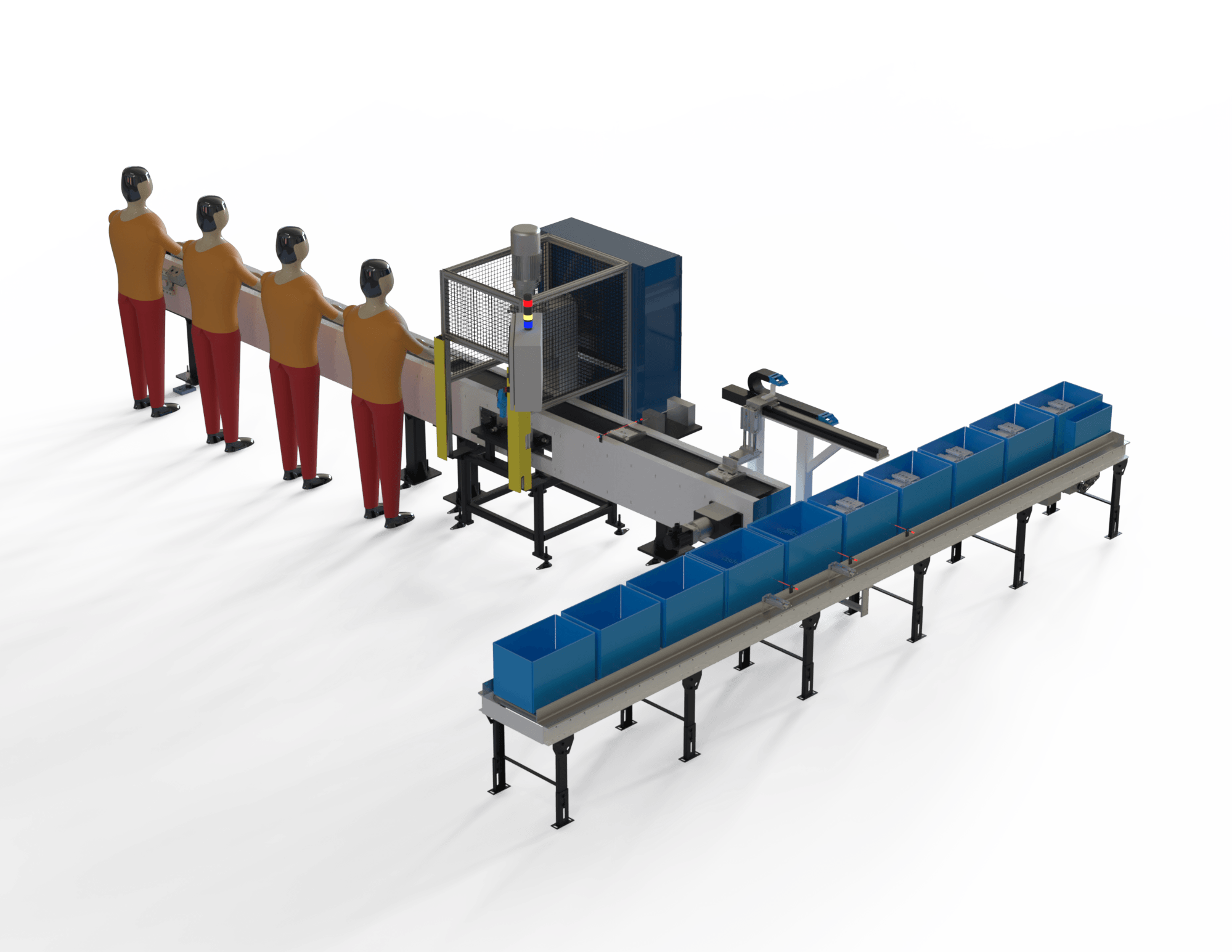

Leveraging our expertise in mechanical design and controls engineering, we delivered a custom-designed semi-automated leak testing machine that met all client requirements.

We categorized our solution into five key steps:

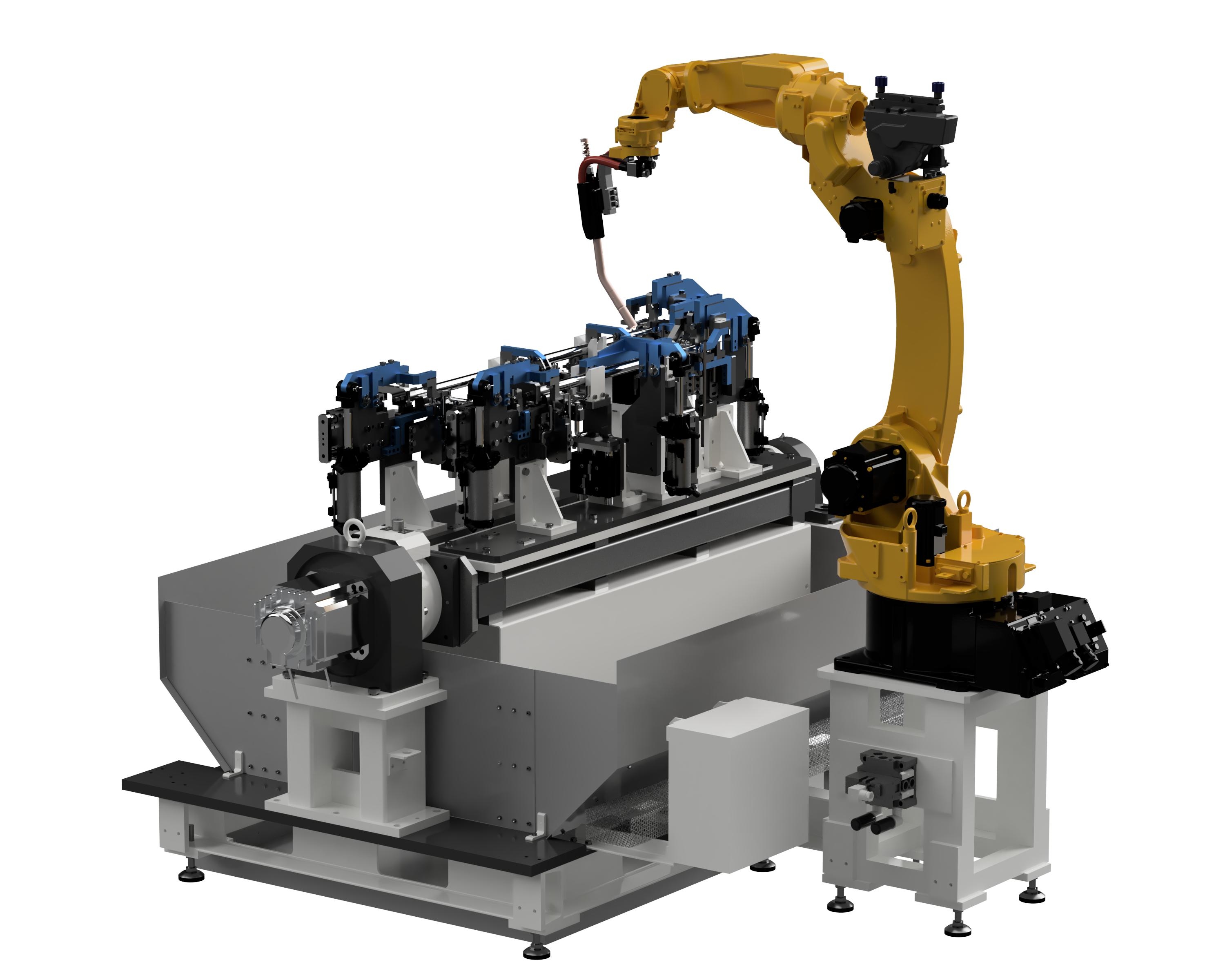

1. Mechanical Design of Leak Testing Machine

After discussing with the client, Sedin’s engineers developed a design concept where both the cylinder head cap and cylinder head body leak tests would run parallelly side-by-side once the cycle starts. This allowed for increased throughput without compromising accuracy.

We optimized the compact design to fit the limited space while maintaining structural integrity and easy access for operators.

2. Precision Fixture Design

To make manual loading and unloading smooth and consistent, the fixtures were designed with foolproof setups, including poka-yoke mechanisms. The fixtures also incorporated resting and clamping units that held the parts securely in place, preventing any errors during testing.

Additionally, PU sealings were integrated and indexed by dedicated cylinders to effectively seal the multiple ports on both cylinder head caps and bodies.

3. Air-Sniffing Leak Testing Technology

The leak test process utilized the air sniffing technique, which required a machine exposed to the open environment for optimal performance. Our precise fixture design ensured that there was zero air leakage during testing, making the system highly accurate and reliable.

We also integrated Cosmo Instruments’ leak tester technology, which enabled precise detection of even the smallest leaks, providing real-time, high-accuracy results.

4. Integrated Part Marking System

To simplify the identification of passed parts, an automatic dot punch marker was added to the machine. This system marked OK parts, making it easy for operators to differentiate between passed and failed components. This feature enhanced the workflow efficiency.

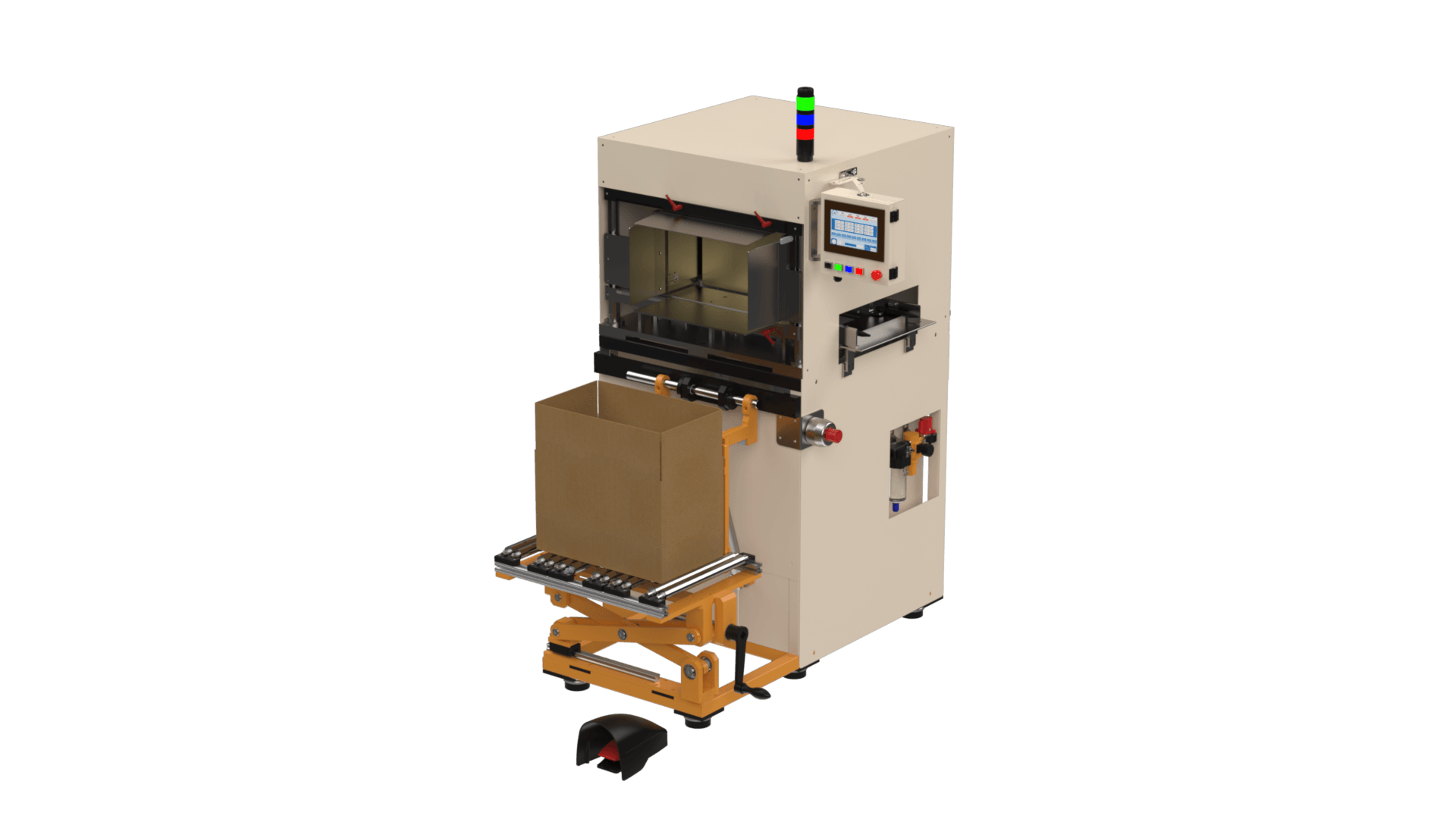

5. Safety and Ergonomics

The machine was designed to meet safety and ergonomic standards recommended by ISO, making it easy and safe for operators to use. Key features included:

– Manual loading/unloading stations positioned for operator comfort and efficiency

– Safety interlocks and light curtains to protect personnel

– A user-friendly HMI interface showing real-time status, maintenance alerts, and fault diagnostics.

All solutions were developed with full consideration of DFMEA (Design Failure Modes and Effects Analysis) to minimize risk and ensure long-term reliability.

The final design resulted in a compact, high-performing, and user-friendly leak testing machine that met every client requirement with precision. Thanks to our efficient and cost-effective automation solution, the machine runs smoothly with minimal downtime, helping the client boost productivity and maintain consistent output on the line.